Drum-type mixer

A mixer and drum-type technology, applied in cement mixing devices, chemical instruments and methods, clay preparation devices, etc., can solve problems such as difficult cleaning of solidified materials, uneven mixing, and affecting quality, and achieve high use value and promotion value , uniform mixing, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

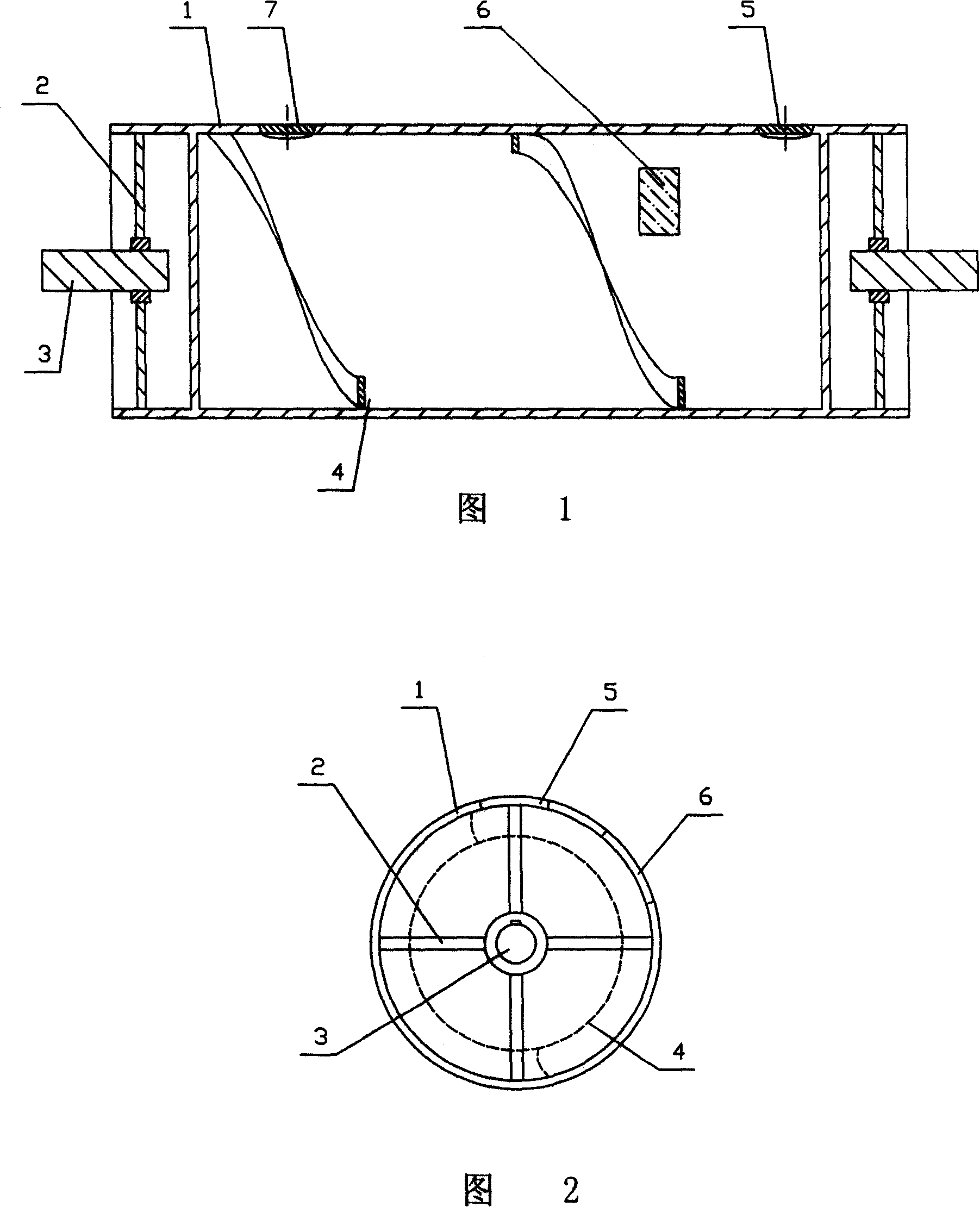

[0015] Embodiment, as shown in Fig. 1, Fig. 2, the drum agitator comprises cylinder body 1, and the two ends of cylinder body 1 are welded support frame 2, and the welding point of support frame 2 is evenly distributed in the inner side of cylinder body 1, and support frame 2 is keyed to connect the drive shaft 3, the inner side wall of the cylinder 1 is welded with a continuous spiral blade 4, one end of the cylinder 1 is provided with a material inlet 5, the other end of the cylinder 1 is provided with a material outlet 7, and the cylinder 1 has at least An observation window 6 is provided.

[0016] A spiral guide groove is formed between the spiral blades 4. When the material enters the cylinder 1 from the feed port, the material will move along the channel surrounded by the cylinder 1 and the spiral blade 4. Every time the cylinder 1 rotates, the spiral The blade 4 pushes the material toward the outlet by one pitch. This propulsion movement not only plays the role of conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com