Ball bearing internal ditch automatic measurement feeding device

An automatic measurement, ball bearing technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of large changes in measurement accuracy and quantity, and achieve the effect of high precision, product quality and quantity assurance, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

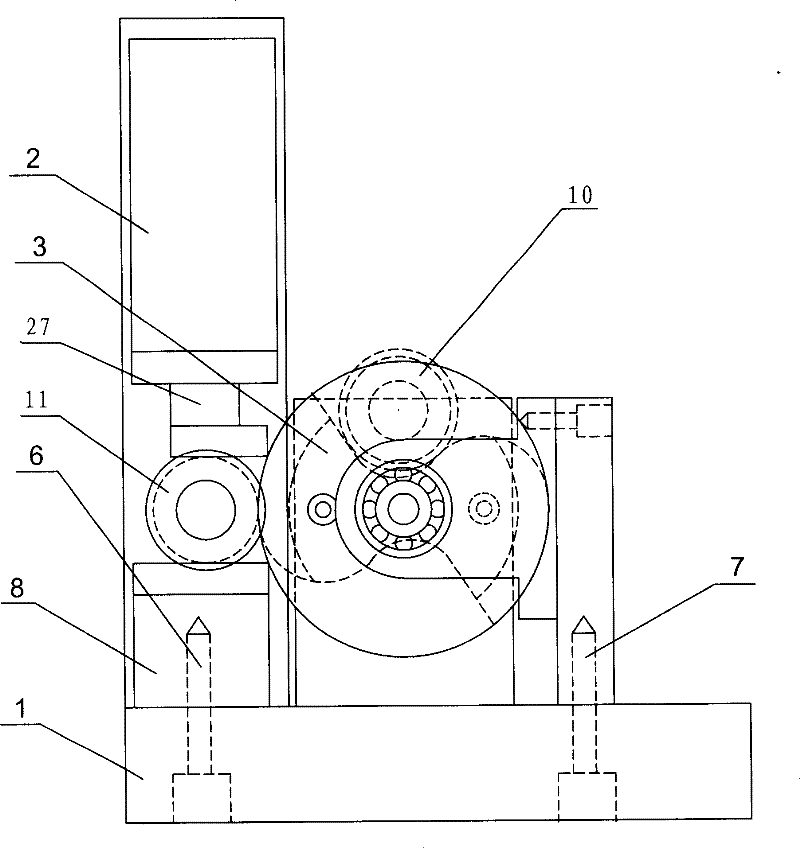

[0019] The automatic feeding device for ball bearing inner groove measurement comprises: a column 5 fixed on the measurement platform 1 with fasteners 6, a measuring mechanism 2 is fixed on the column 5 by fasteners 4, and the measurement An upper measuring slideway 27 is installed in the mechanism 2 , a loading and unloading device 3 is fixed on the measuring platform 1 , and a lower measuring slideway 8 is fixed on the measuring platform 1 .

Embodiment 2

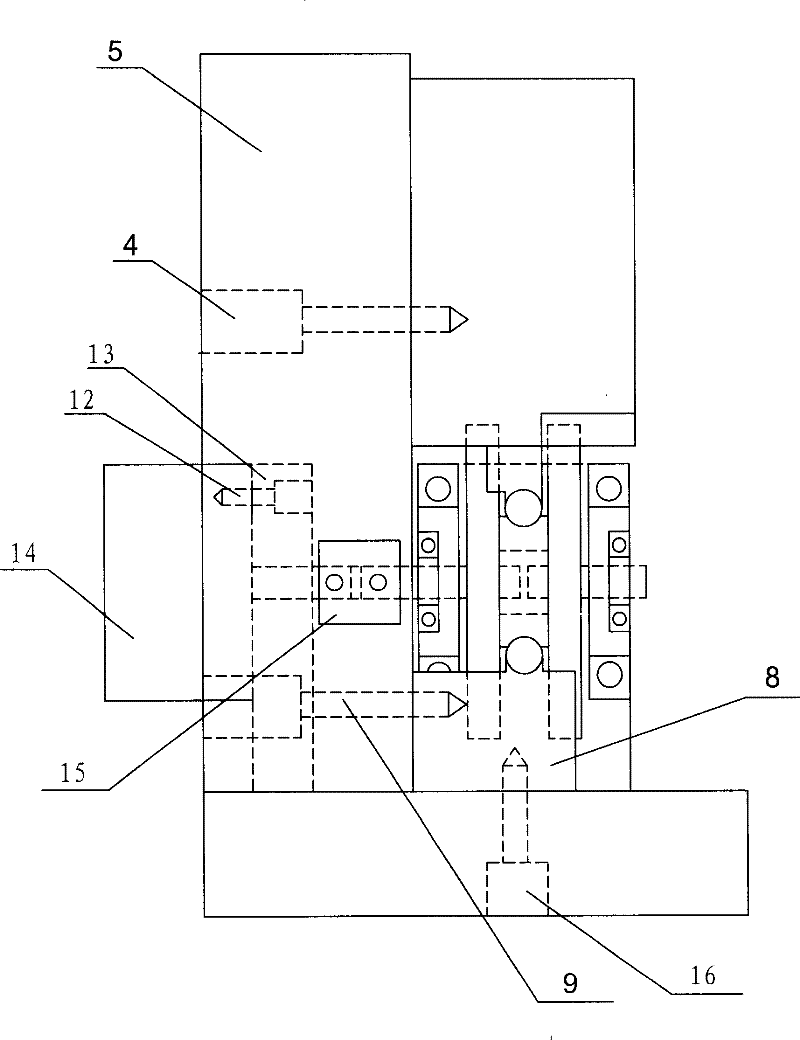

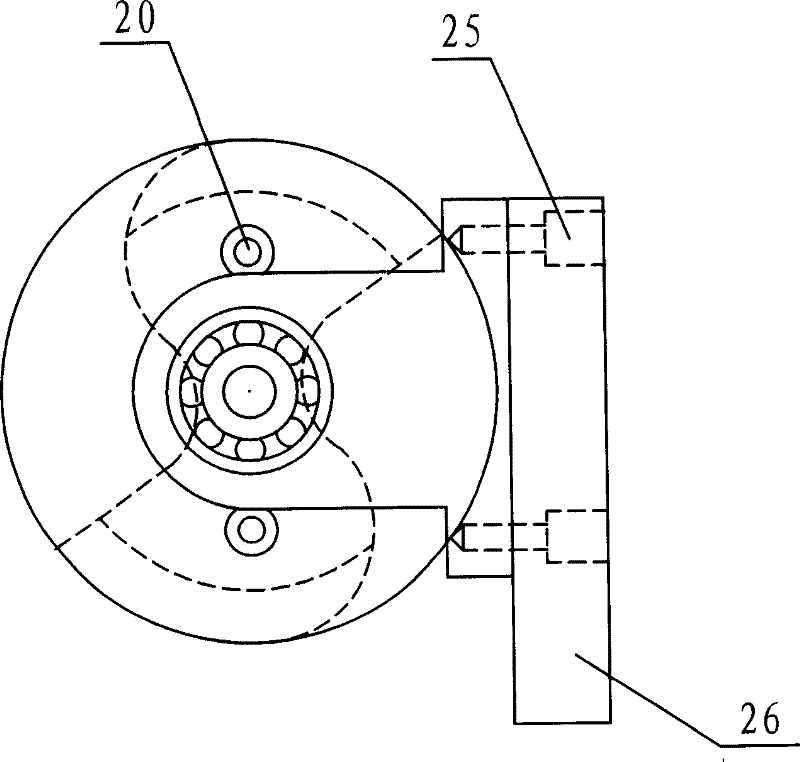

[0021] The above-mentioned automatic feeding device for ball bearing inner groove measurement, the described loading and unloading device 3 includes a feed wheel 17, a left side plate 18 of the feed wheel, and a right side plate 19 of the feed wheel, and the three are connected by a fastener 20 Together, the long axis end of the left side plate 18 of the feed wheel is connected with the left bearing 22, the left bearing pad seat 21, the short axis of the right side plate 19 of the feed wheel is connected with the right bearing 24, the right bearing The shoe seat 23 is connected, the left bearing shoe seat 21 and the right bearing shoe seat 23 are fixed on the bearing shoe seat support plate 26 by the fastener 25, and the bearing shoe seat support plate 26 is fixed by the fastener 7 is fixed on the measuring platform 1.

Embodiment 3

[0023] In the above-mentioned automatic feeding device for ball bearing inner groove measurement, the shape of the surface of the inner sleeve of the bearing pushed by the feed wheel and the measurement surface of the upper and lower measurement slideways is an arc whose radius is smaller than the radius of the steel ball in the bearing, so The feed wheel is involute toothed, the long axis of the left side plate 18 of the feed wheel is connected to the stepper motor 14 through a coupling 15, and the stepper motor 14 is fixed by a fastener 12 On the stepper motor support 13 , the stepper motor support 13 is fixed on the measurement platform 1 with fasteners 16 . Make sure that each workpiece is sent to a relatively fixed position on the measurement surface.

[0024] Work Engineering Description:

[0025] In the above-mentioned automatic feeding device for ball bearing inner groove measurement, the workpiece 10 to be detected enters the feed wheel 17 under the action of gravity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com