Composite microwave medium ceramic material

A technology of microwave dielectric ceramics and ceramics, applied in the field of dielectric ceramics, to achieve stable process, excellent microwave dielectric properties, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this experiment, high-purity Li 2 CO 3 , Nb 2 o 5 and TiO 2 raw material. The raw materials are mixed according to the chemical ratio of a=0.05, b=0.075; d=0.01 in the formula composition, and deionized water is added according to the weight ratio of the mixture and deionized water at 1:1.8, and mixed by wet ball milling for 24 ~36h, dry at 100~150°C, put them into high alumina crucibles respectively, pre-fire at 700°C~900°C for 5h~8h, and synthesize the required main crystal phases respectively. Mix the above-mentioned pre-synthesized powders at a molar ratio of 1:1, add alcohol according to the weight ratio of the mixture to alcohol at 1:1.2, and discharge the material after wet ball milling for 24h~36h, at 100~150℃ Drying, granulation with 4%-8% PVA, pressing into small discs under a pressure of 100-200MPa, debinding at 600-700°C. Undoped B 2 o 3 The ceramic sample is placed in an alumina crucible and sintered at 1000° C. to 1200° C. for 1 to 3 hours and n...

Embodiment 2

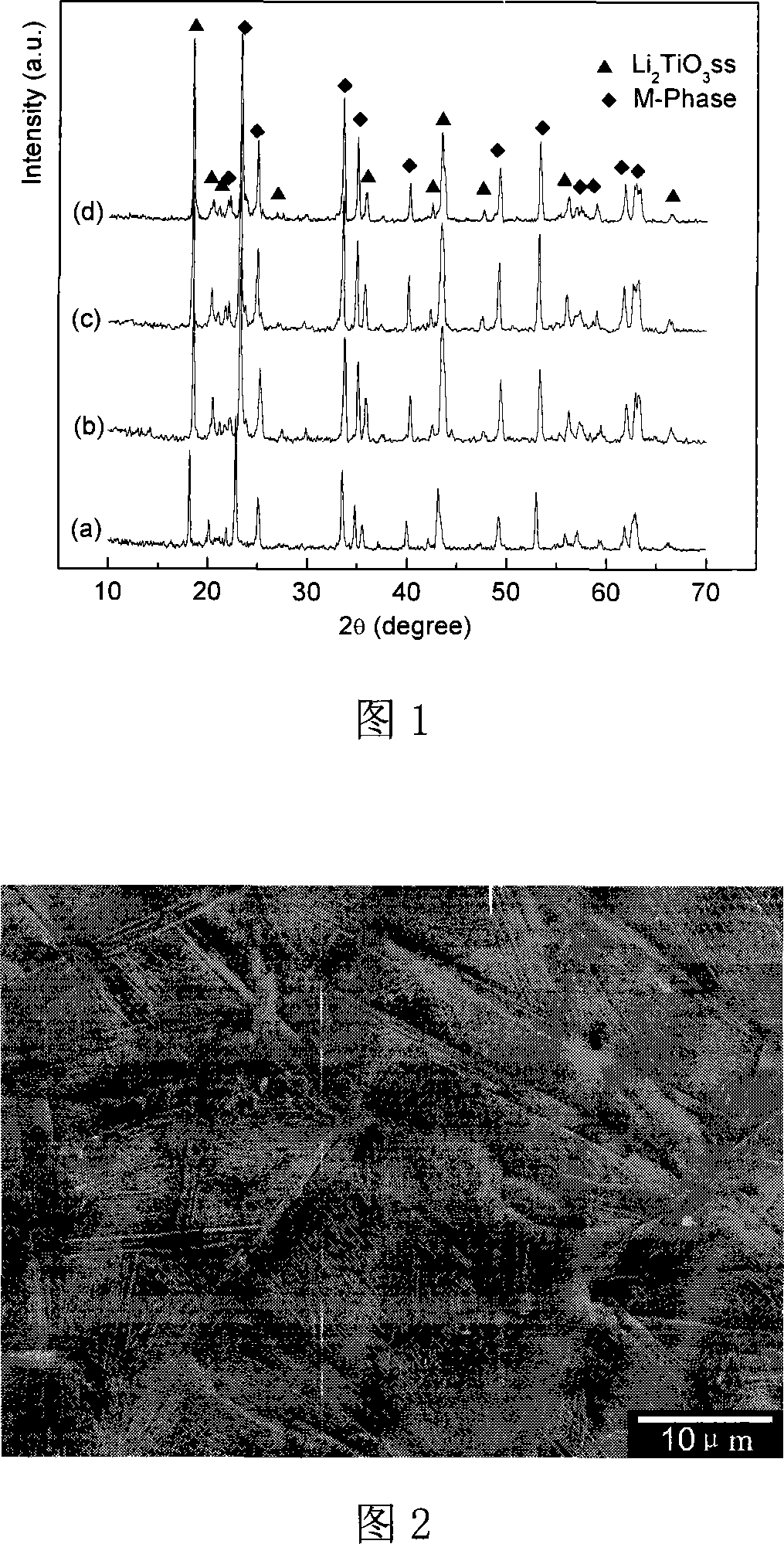

[0032] In this experiment, high-purity Li 2 CO 3 , Nb 2 o 5 and TiO 2 raw material. The raw materials were mixed according to the stoichiometric ratio of a=0.05, b=0.05; d=0.03, and the main crystal phases of the above compositions were respectively synthesized according to the preparation process described in Example 1. The above-mentioned pre-synthesized powders are mixed according to the molar ratio of 1:1, and the preparation process described in Example 1 is adopted to prepare the ceramic material of the above composition. The ceramic sample is to be tested after being ground on both sides by sandpaper. . Through the test of the microwave performance, the microwave dielectric properties of the composite ceramic material at different sintering temperatures are shown in Table 2, and the phase composition of the ceramic sheet sintered at 1100 ° C was identified by X-Ray (accompanying drawing 1 (b) The X-Ray diffractogram of the example 2 sample at 1100 ° C sintered cer...

Embodiment 3

[0036] In this experiment, high-purity Li 2 CO 3 , Nb 2 o 5 and TiO 2 raw material. The raw materials are mixed according to the chemical ratio of a=0.05, b=0.1; d=0.07, and the weight ratio of the mixture to the deionized water is 1:1.8, and the deionized water is added respectively, and the wet ball milling method is mixed for 24 to 36 hours. Dry at 100-150°C, put them into high-alumina crucibles respectively, and pre-fire at 700°C-900°C for 5h-8h to synthesize the required main crystal phases respectively. Mix the above-mentioned pre-synthesized powders at a molar ratio of 1:1, add alcohol according to the weight ratio of the mixture to alcohol at 1:1.2, and discharge the material after wet ball milling for 24h~36h, at 100~150℃ Drying, granulation with 4%-8% PVA, pressing into small discs under a pressure of 100-200MPa, debinding at 600-700°C. Undoped B 2 o 3 The ceramic sample is placed in an alumina crucible and sintered at 1000° C. to 1200° C. for 1 to 3 hours an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com