Device for harmlessly conversing plastic rubber garbage to combustible gas

A gas device and garbage technology, applied in the field of plastic garbage recycling equipment, can solve the problems of non-renewable value, rubber garbage polluting the environment, etc., and achieve the effects of outstanding environmental and social benefits, significant economic benefits, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

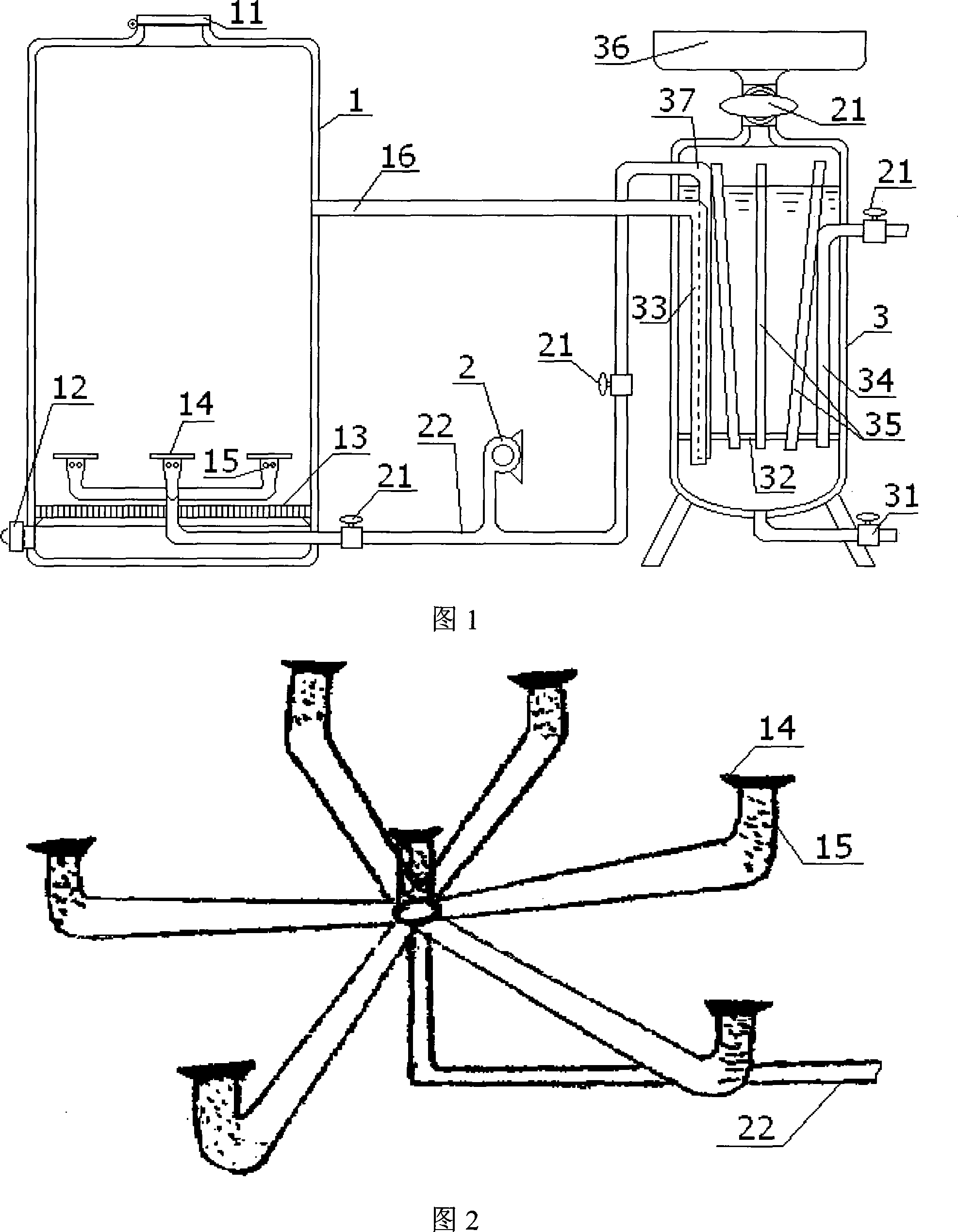

[0023] Embodiment 1, as shown in Figure 1, the device for the harmless conversion of plastic waste into combustible gas according to the present invention includes a gasification furnace and a cooling liquid remover with cooling and gas-liquid separation functions. The gasification furnace includes an upper end with a feeding port 11, a lower end A vertical furnace body 1 with a slagging outlet 12, the furnace body 1 is equipped with a furnace grate 13 above the slagging outlet 12, and an air nozzle 15 with a cover plate 14 on the top and a gas injection port on the side of the furnace grate 13 is arranged. The nozzle 15 is connected to the air blower 2 through the air regulating valve 21 and the air pipe 22, and the upper side of the furnace body 1 is connected with an air outlet pipe 16; the air outlet pipe 16 is further connected to the cooling liquid remover.

[0024]The cooling liquid remover includes a vertical tank body 3 with a drain valve 31 at the bottom, a partition ...

Embodiment 2

[0025] Embodiment two, as shown in Figure 2, its difference with embodiment one is that described air nozzle 15 is that a central air nozzle 15 is arranged in the middle, and six peripheral air nozzles 15 are evenly arranged on the circumference of central air nozzle 15, Air nozzle 15 top still has cover plate 14.

Embodiment 3

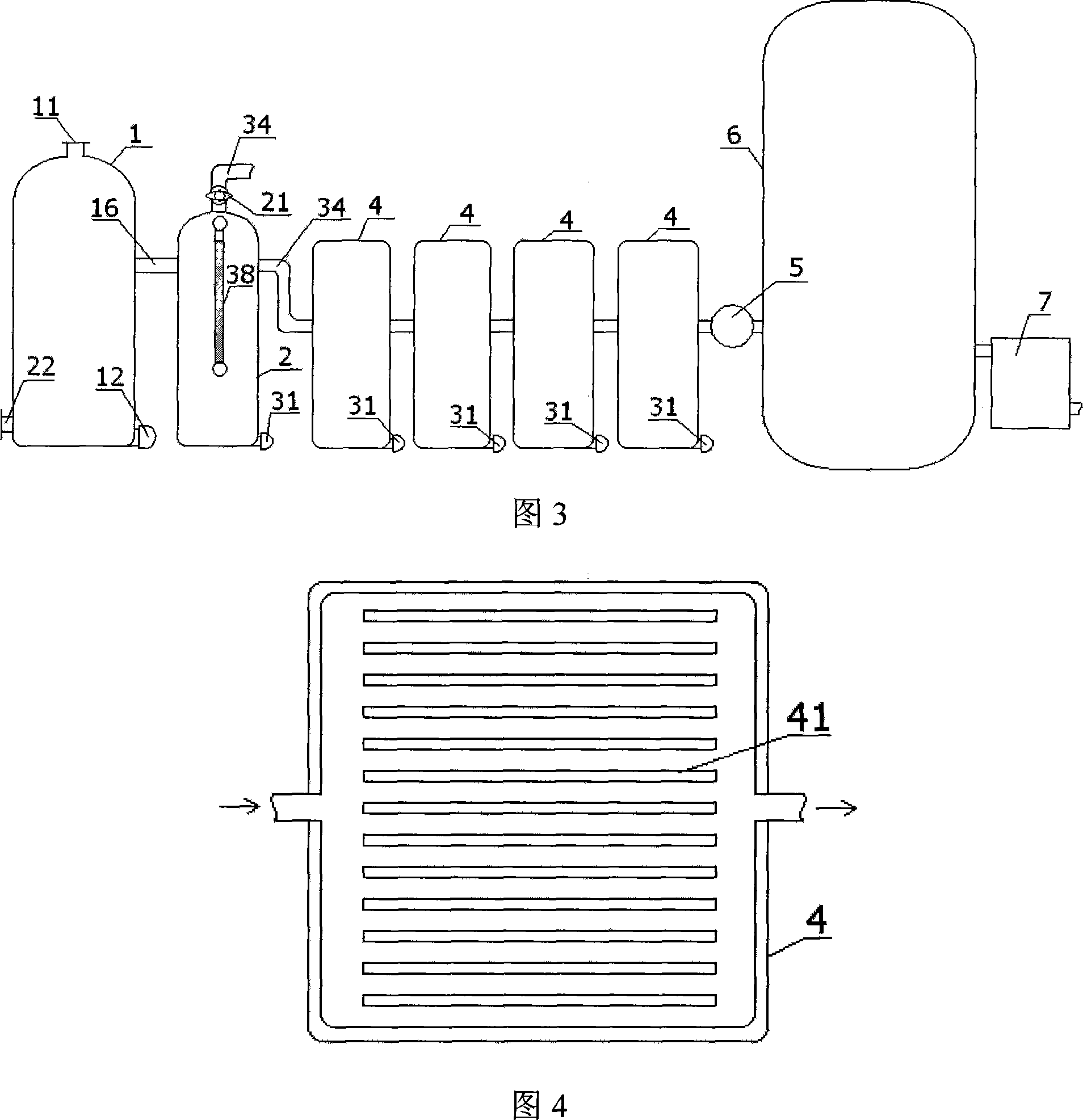

[0026] Embodiment 3, as shown in Figures 3 and 4, the difference between the harmless conversion of plastic waste and combustible gas device of the present invention and Embodiment 2 is that a water level gauge 38 is installed on the vertical tank body 3 of the cooling eliminator, and the tank body 3 The top is connected to a clean air pipe 34 through an air regulating valve 21 . After the side cleaning air pipe 34 of the cooling deliquidator is connected in series with four buffer adsorption tanks 4 with a drain valve 31 at the bottom, the pressurized cooling pump 5 is further connected to the gas storage tank 6 with a drain valve 31 at the bottom. The gas storage tank 6 is connected to the liquefied gas storage tank through the liquefaction device 7; the buffer adsorption tank 4 is built with glass adsorption plates 41 densely distributed in the same direction as the air flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com