Hub-shape knife and cutting device

A cutting device and cutting tool technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems such as difficult disassembly and assembly, and achieve the effects of improving productivity, ensuring disassembly and assembly, and ensuring cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

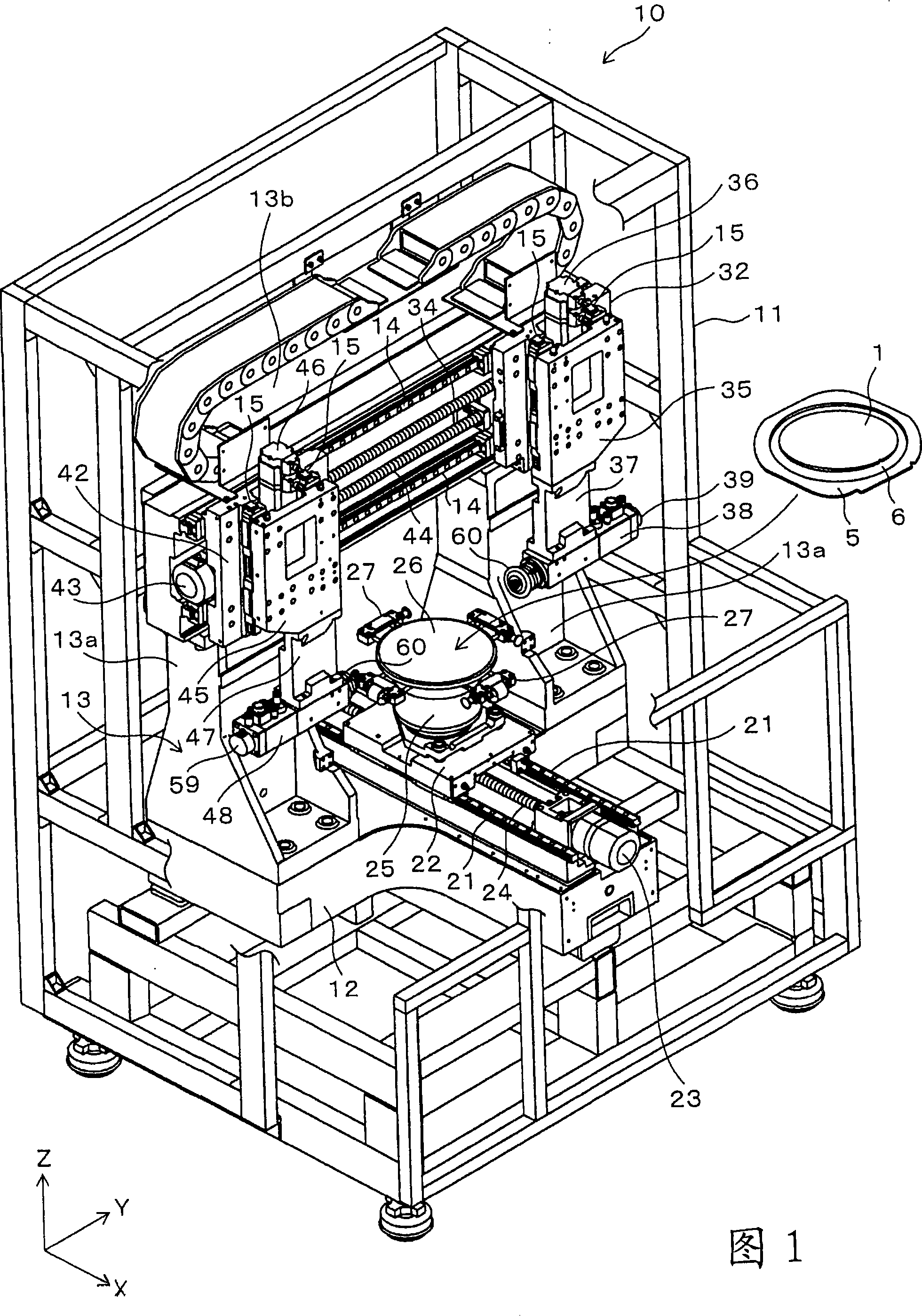

[0036] One embodiment of the present invention will be described below with reference to the drawings.

[0037] FIG. 1 shows a dual-axis opposed cutting device 10 according to one embodiment. Reference numeral 11 in FIG. 1 is the main frame of the whole device, a base frame 12 is fixed on the bottom inside the main frame 11 , and a portal column 13 is fixed on the base frame 12 . A pair of X-axis linear guides 21 extending in the X-axis direction are provided at the center of the base frame 12 , and X-axis sliders 22 are slidably attached to these X-axis linear guides 21 . The X-axis slider 22 is reciprocated along the X-axis linear guide 21 by the ball screw feed mechanism 24 driven by the X-axis feed motor 23 . A disk-shaped suction table 26 is provided on the X-axis slider 22 via a suction table base 25 .

[0038] The suction cup table 26 is rotatably supported on the suction cup table base 25 about the Z-axis direction (vertical direction), and is driven to rotate clockw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com