High pressure high speed rotation joint

A high-speed rotation, high-pressure technology, applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc., can solve the problems of backward design structure, locking between the mandrel and the stator, etc., to achieve reasonable structure, easy maintenance, The effect of meeting technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

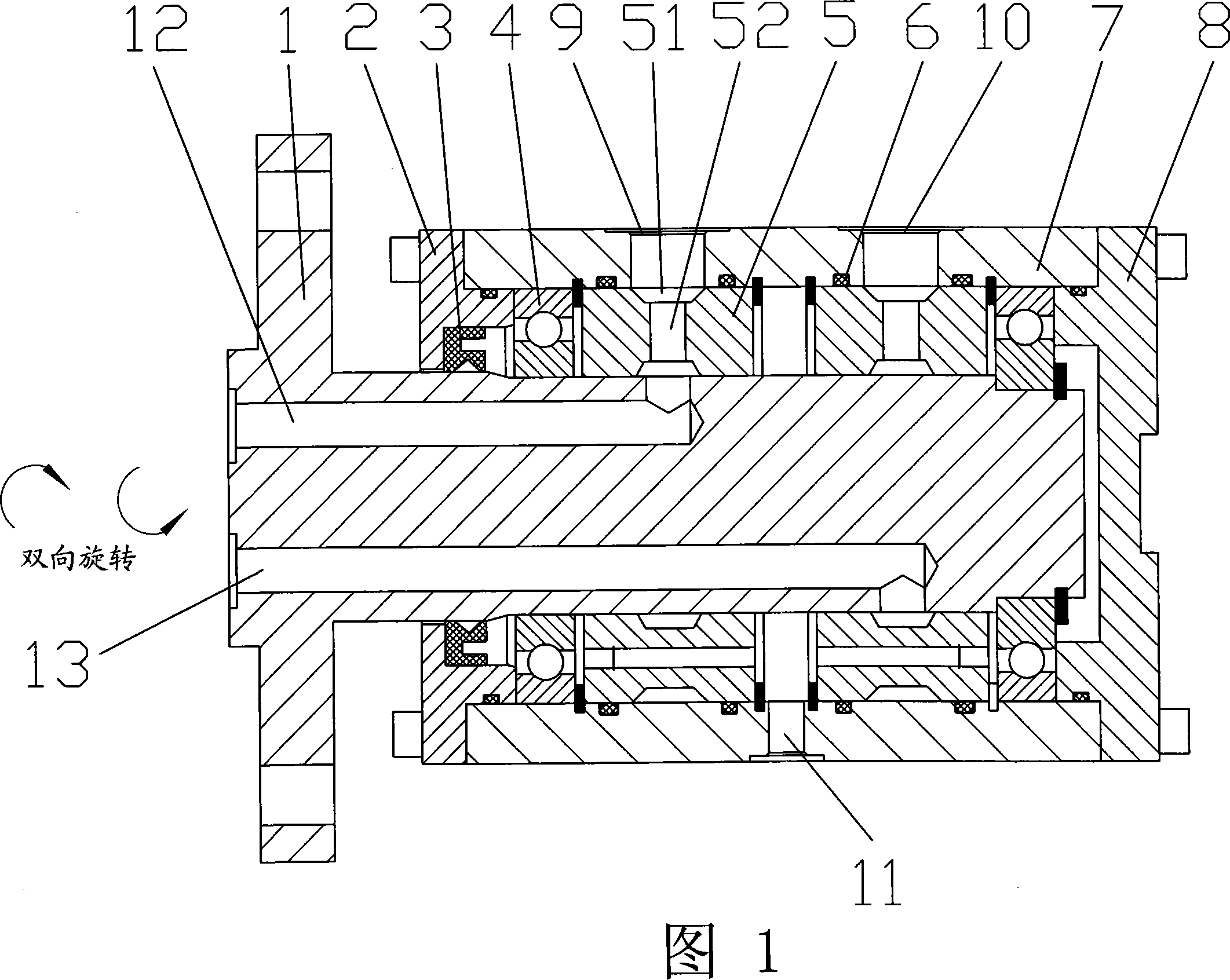

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] Referring to Figure 1, a high-pressure, high-speed rotary joint includes a shaft core 1 and a housing 7. The shaft 1 rotates at a high speed while the housing 7 is stationary. The shaft 1 is fixedly connected with the hydraulic cylinder and together with the main engine Rotation, a servo ring 5 is installed between the housing 7 and the mandrel 1, the servo ring 5 is controlled by the "O" ring 6 and the working pressure, the "O" ring 6 adopts a high-precision "O" ring to achieve Constant gap control and servo self-adjusting centering control, the working medium enters the working oil port A9 or working oil port B10 on the casing 1 through the pipeline, and is input and connected with the fixed casing 7 and the fixed servo ring 5. The mandrel 1 that rotates together with the main machine goes to the main machine to realize the continuous transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com