Digitalized torque measuring and loading device

A technology of loading device and torque measurement, applied in the direction of measurement device, force/torque/work measuring instrument calibration/test, instruments, etc., can solve the problems of large system operation error, low degree of standardization, and unstable connection method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

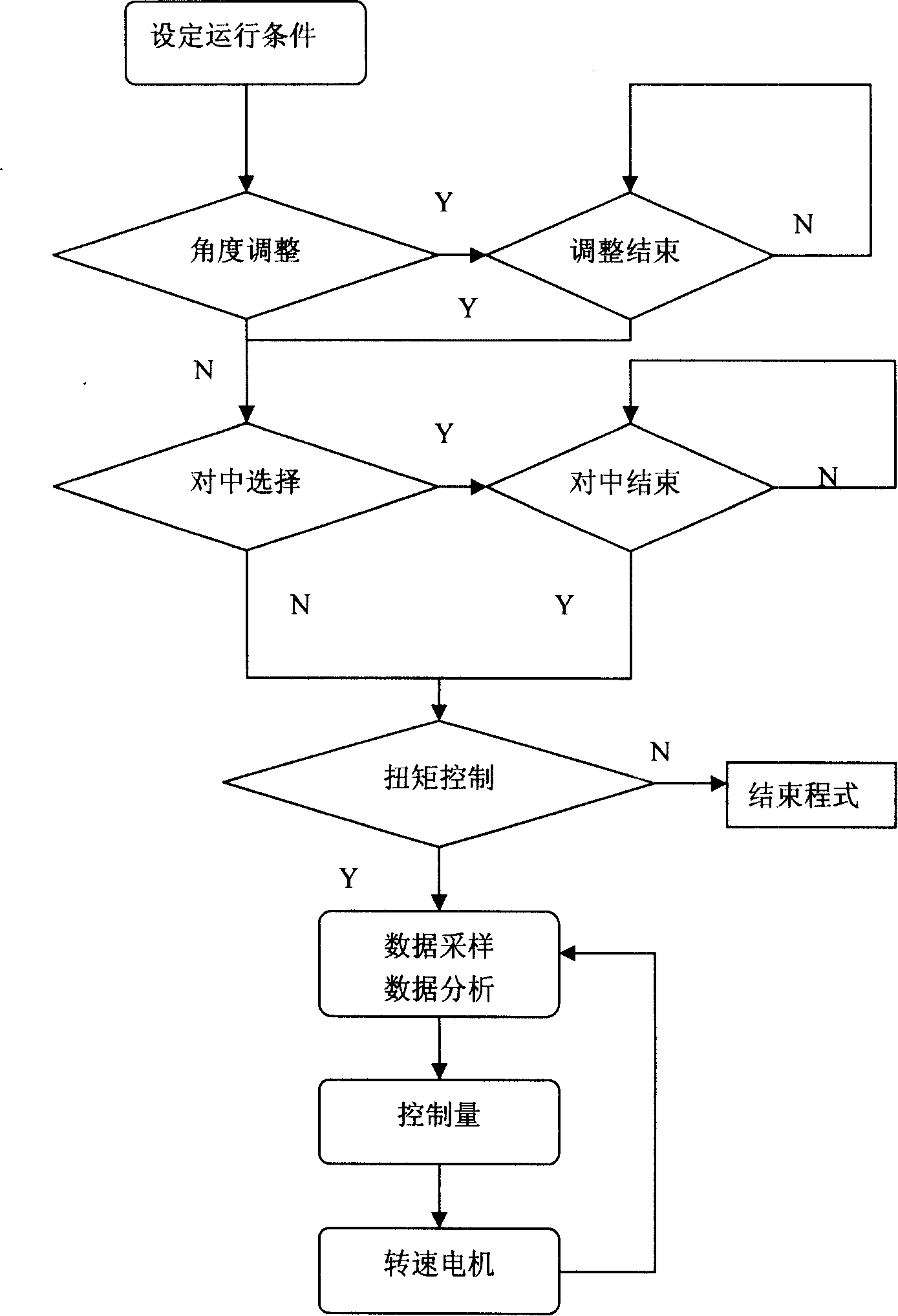

[0006] Embodiment 1: with reference to accompanying drawing. The main frame of the machine in this embodiment adopts the gantry plus platform chute structure, the loading head is at the upper center of the gantry, and can be adjusted arbitrarily within the range of 90° vertically and horizontally to the horizontal plane, and the angle adjustment is electric adjustment, with automatic And manual adjustment button, just input the angle to be adjusted in automatic mode, and press the button until the set angle is reached in manual mode, and release it, and it is designed with anti-loose locking mechanism, which can be adjusted at 90°~0° Lock at any angle.

Embodiment 2

[0007] Embodiment 2: with reference to accompanying drawing. This embodiment adopts an automatic centering device. When the tested instrument is placed on the clamping position of the platform, press the clamping button and the tested instrument is automatically clamped. The position of the tested instrument on the horizontal plane can be automatically adjusted by the laser scanning system to the center of the loading part of the tested instrument. That is to automatically make the loading rotation axis of the tested instrument coincide with the power loading rotation axis; during the test, the laser scanning system first automatically scans the position difference between the current position and the active loading axis, and the system automatically adjusts the position left and right, front and back according to the difference. The loading axis of the tested instrument coincides with the power loading rotation axis.

Embodiment 3

[0008] Embodiment 3: with reference to accompanying drawing. This embodiment adopts dual control of computer and man-machine interface, both of which can simultaneously display various values such as speed, torque, time, etc., and the computer can also display various related change curves, and all display signals come from DEWE-DSA series dynamic signal analyzers . When the computer is turned on, the computer takes priority control, and the man-machine interface touch screen only displays the content. When the computer is not turned on, the man-machine interface touch system can control the entire system and also undertake the display work. The two do not interfere with each other and form a self-contained system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com