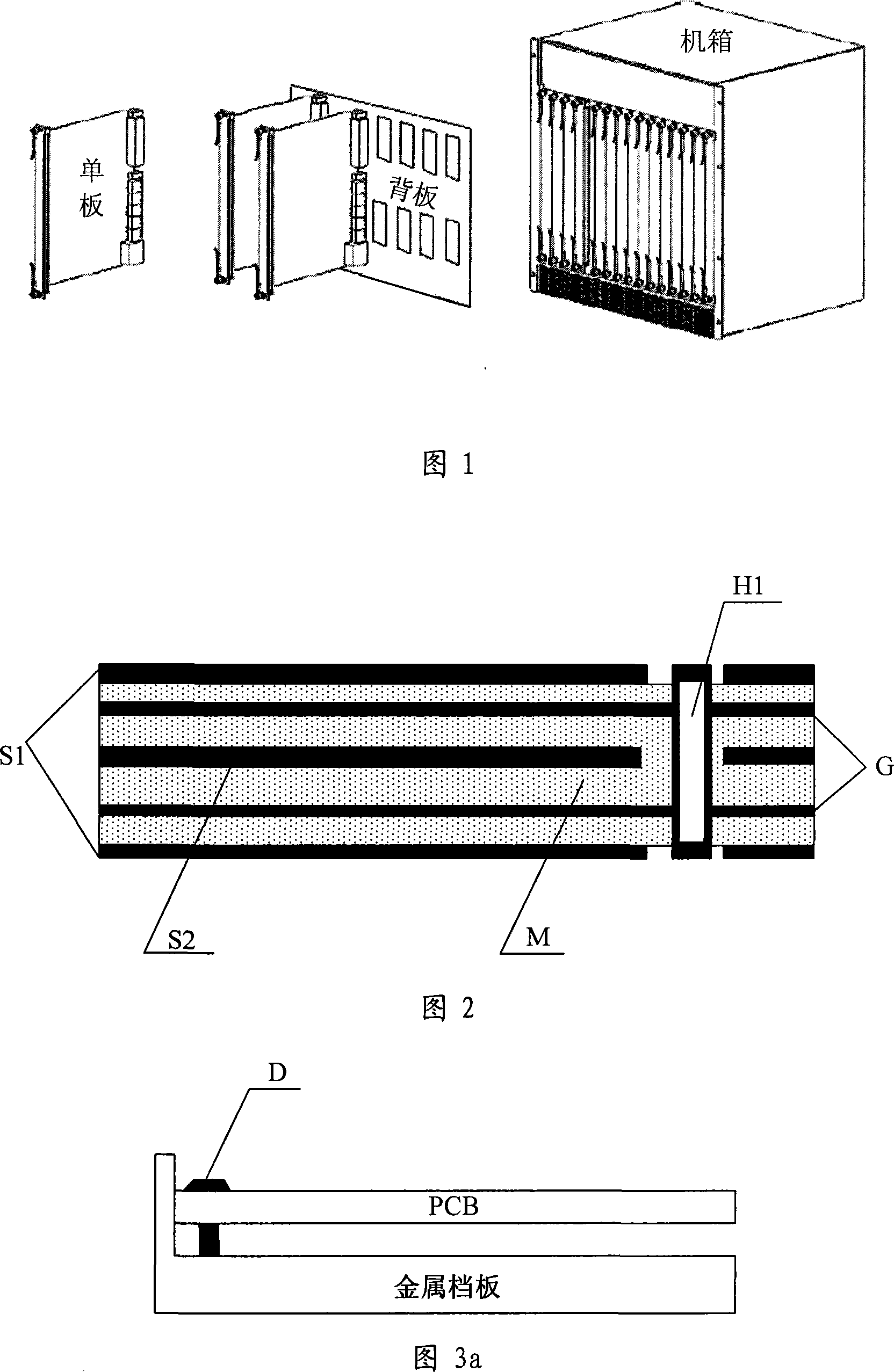

Single plate structure

A single board and baffle technology, applied in the fields of magnetic field/electric field shielding, electrical components, etc., can solve the problems of poor EMI suppression performance, different noise discharge paths, waste of time and cost, etc., to avoid single connection method, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

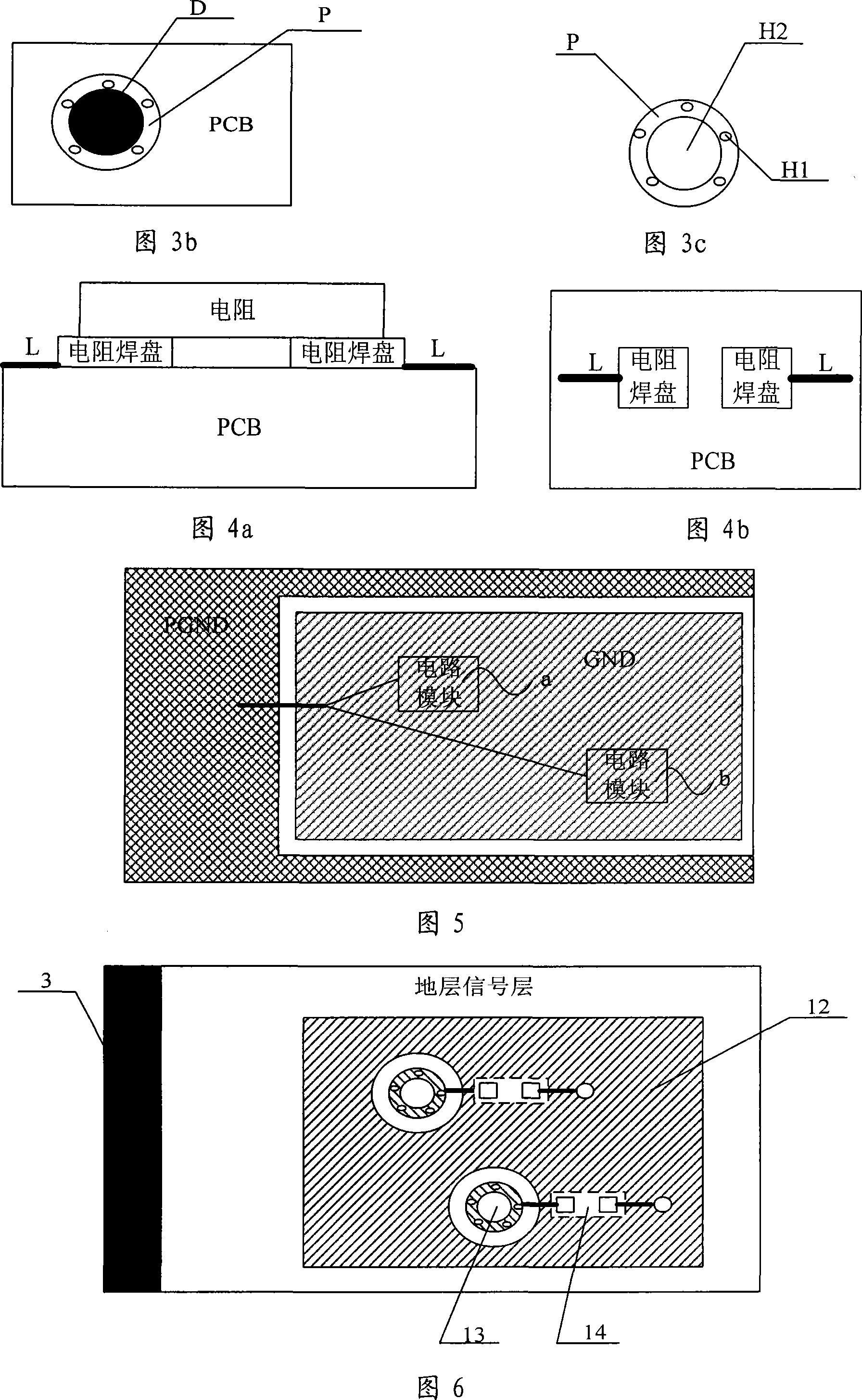

Method used

Image

Examples

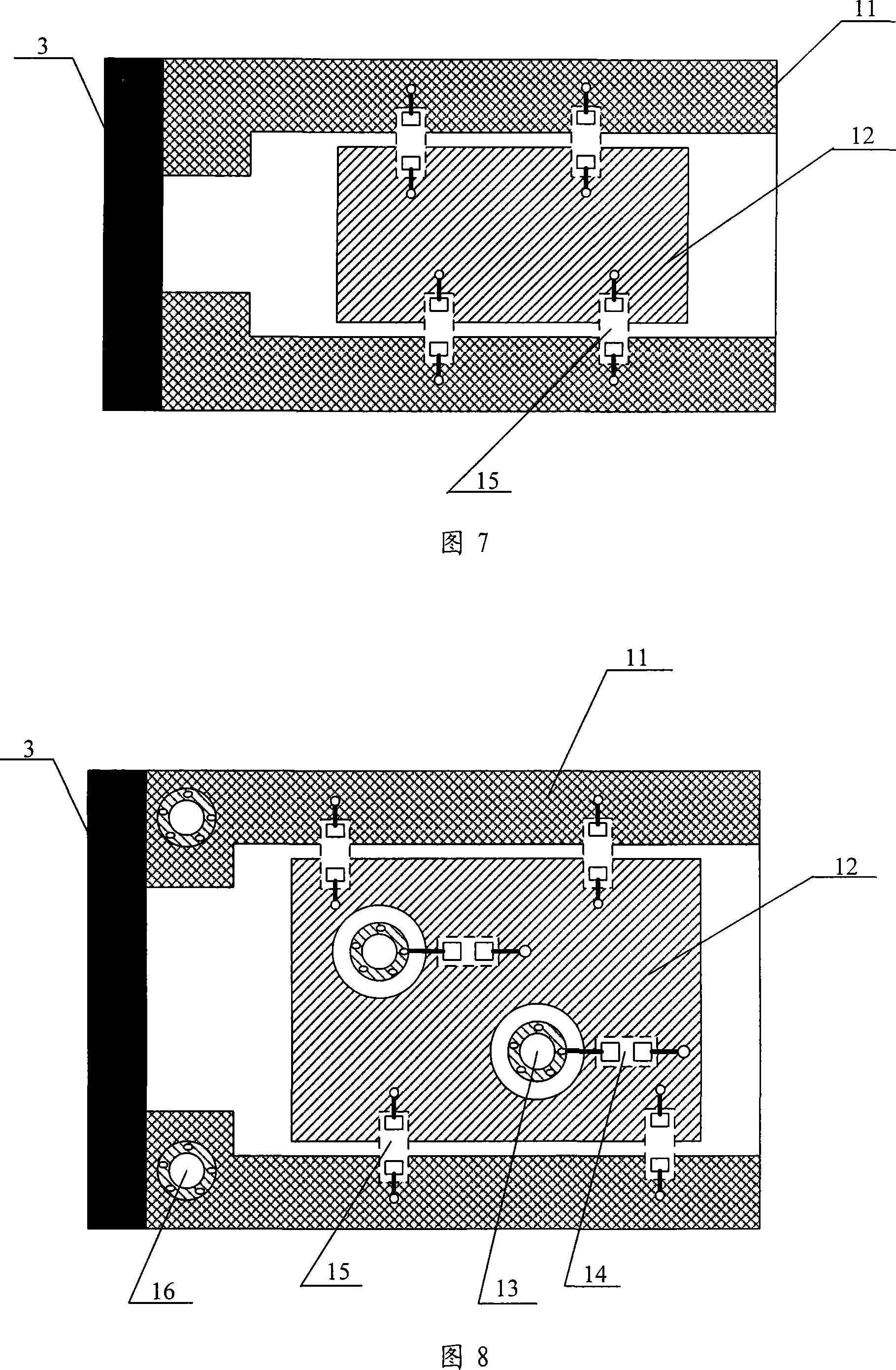

Embodiment 3

[0030] Embodiment 3, through the distribution of the screw holes in the working area, soldering points are reserved for the connection between the working area and the ground, and the screw holes are distributed according to the positions of the sensitive circuit modules, so that the sensitive circuit modules can be provided with the closest noise leakage. It is beneficial to suppress EMI; at the same time, by reserving welding points in the protected area and the working area, the connection mode between the working area and the protected area can be flexibly selected according to the actual application, and the type of noise discharge path can be flexibly selected. The choice of multi-point connection or single-point connection avoids the risk of redesigning and re-manufacturing the board when changing the connection mode between the working area and the protection area, and saves time and cost.

[0031] The side views of Embodiment 1 and Embodiment 2 of the veneer structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com