Big and small impeller vane impeller with non-full height small blade and compressor machine

A blade impeller and small blade technology, applied in the field of blade impeller mechanical devices, can solve the problems of complex blade structure and low efficiency, and achieve the effect of suppressing secondary flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

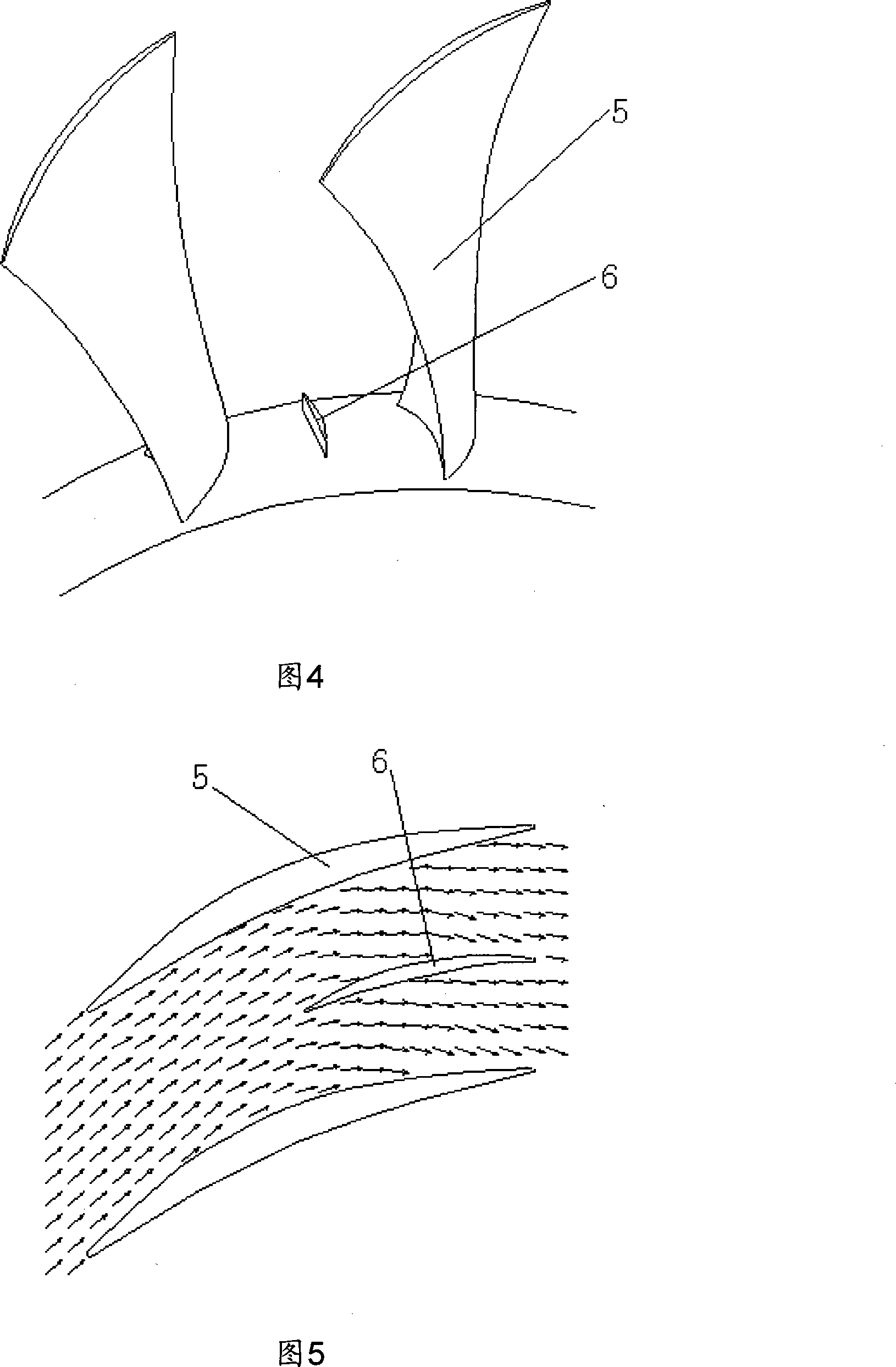

[0019] The large and small blade impeller with non-full-height small blades of the present invention, its preferred specific embodiment is shown in Figure 4, including a plurality of large blades 5, and small blades are arranged between two adjacent large blades 5 6. The radial height of the small blade 6 may be less than or equal to 20% of the height of the large blade 5, and may be 3%, 10%, 15%, 20% and so on.

[0020] The axial chord length of the small blade 6 may be 30%-85% of the axial chord length of the large blade 5, and may be 30%, 45%, 55%, 70%, 85% and so on. That is to say, the small blade is not full size in the axial direction, but starts from a certain position in the axial direction. The trailing edge of the small blade 6 can be flush with the trailing edge of the large blade 5, or it can be slightly ahead of or behind the rear of the large blade 5. edge.

[0021] The starting arc of the small blade 6 can be the same as the central arc of the large blade 5 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com