Cobalt-vanadium super-high density vertical magnetic recording medium and method for making same

A perpendicular magnetic recording, ultra-high density technology, applied in the direction of magnetic recording, data recording, recording information storage, etc., can solve the problem of low thermal stability of the medium, and achieve simple equipment, controllable grain size, and high magnetic crystal density. Anisotropic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

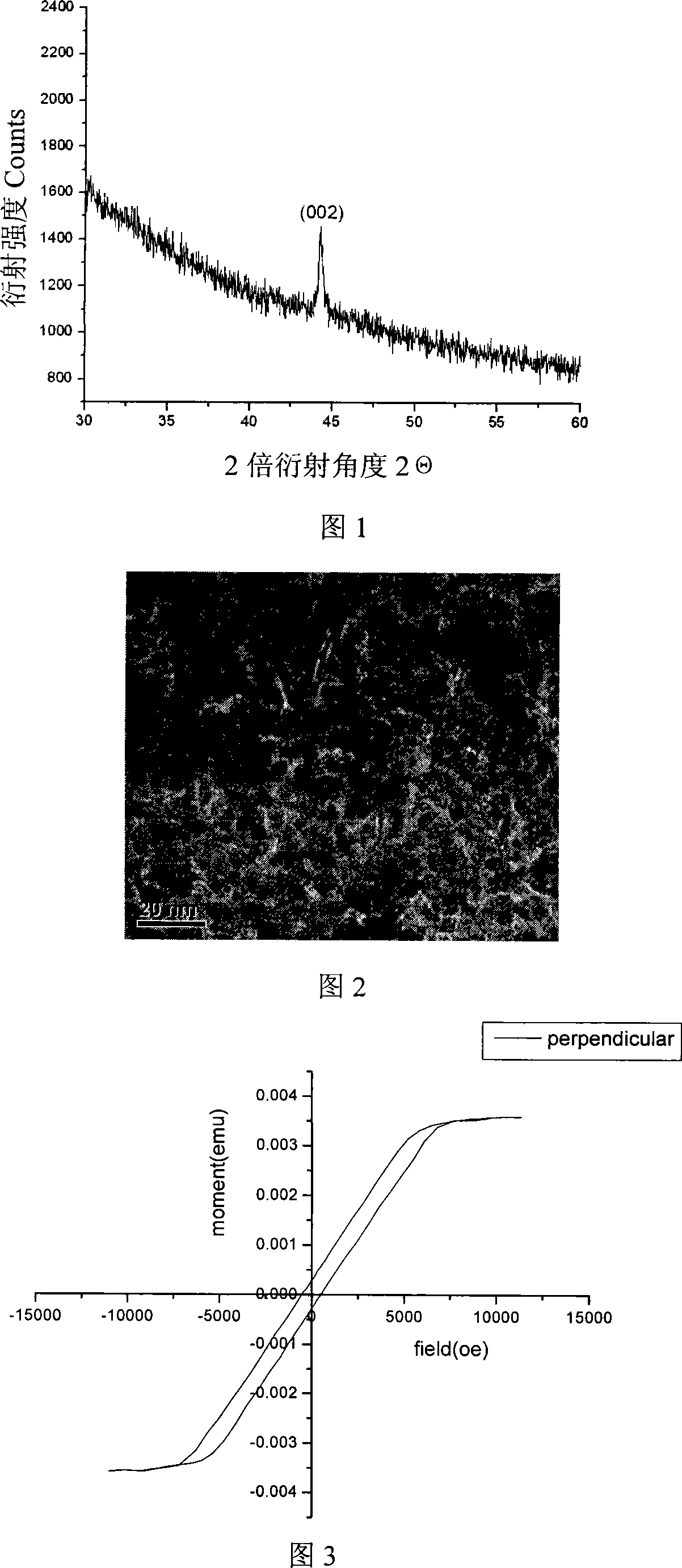

[0018] Example 1: Preparation of Co with a thickness of 600nm at 200°C 87 V 13 film

[0019] 1) Clean the glass substrate ultrasonically with alcohol, acetone, and distilled water, then soak it in chromic acid for 12 hours, then wash it with distilled water, and finally dry it with a nitrogen gun. Put the cleaned glass substrate into the sputtering chamber, install the cobalt target at the same time, place some small vanadium chips on the cobalt target to adjust the content of vanadium, so that the composition of the film is Co 87 V 13 ;

[0020] 2) The sputtering chamber is pumped until the background vacuum is better than 5×10 -4 Pa;

[0021] 3) Heating the sputtering chamber to keep the substrate temperature at 200°C;

[0022] 4) Introduce Ar gas, keep the air pressure at 0.6-0.7Pa, and the target distance is 7cm. Then start the pre-sputtering for 30 minutes to clean the target surface, and then use the power of 300W to sputter and deposit for 60 minutes. Sputter and ...

Embodiment 2

[0023] Example 2: Preparation of Co with a thickness of 600nm at 250°C 87 V 13 film

[0024] The same procedure as in Example 1 was adopted, wherein the sputtering temperature was 250°C. Different temperatures have certain effects on the uniformity and grain size of the film structure.

Embodiment 3

[0025] Example 3: Preparation of Co with a thickness of 600nm at 300°C 87 V 13 film

[0026] The same procedure as in Example 1 was adopted, wherein the sputtering temperature was 300°C. Different temperatures have certain effects on the uniformity and grain size of the film structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com