Preparation method of Cr-based chalcogenide hard magnetic nanomaterial

A technology of chalcogen compounds and nanomaterials, which is applied in the fields of magnetic materials, inorganic materials, inductors/transformers/magnets, etc., can solve the problems of complex preparation process and low coercive force of rare earth-free magnetic nanomaterials, and achieve simplified preparation Process, high coercive force, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

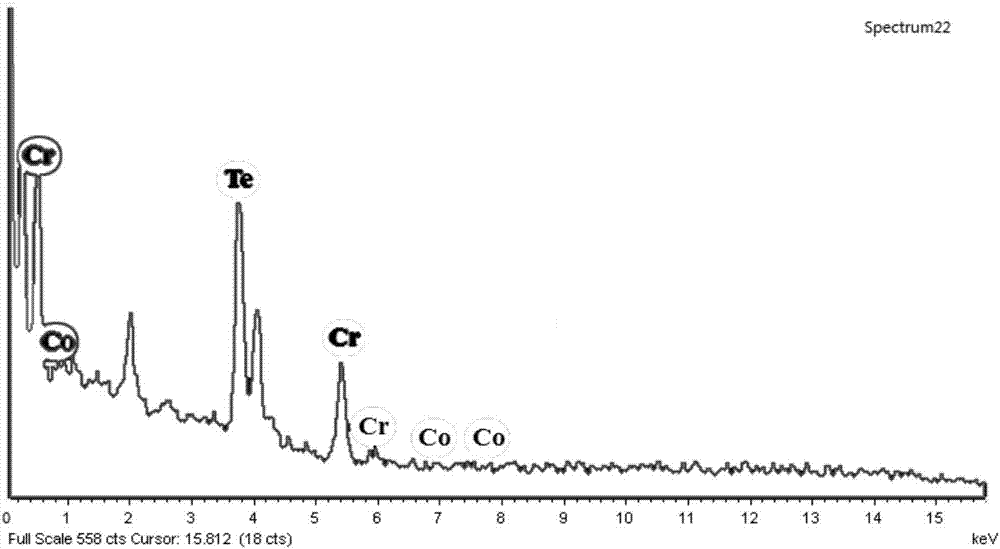

[0038] This embodiment provides a Cr-based chalcogen compound hard magnetic nanomaterial, which is obtained through the following preparation steps:

[0039] (1) 1.9mmol of Cr(CO) 6 , 0.1mmol of Co(acac) 2 and 30mL oleylamine were added to a four-necked flask equipped with a temperature regulator and a magnetic stirrer to obtain a solution containing Cr and Co. 2 Warm up to 120°C under protection and keep warm for 30min;

[0040] (2) Dissolving 3.0 mmol of Te elemental powder in 5 mL of trioctyl phosphine (TOP) to obtain a suspension solution containing Te;

[0041] (3) Inject the suspension solution containing Te into the solution containing Cr and Co, raise the temperature to 400°C at a heating rate of 5°C / min under the protection of nitrogen, and keep the reaction for 1h to obtain Cr 1.9 co 0.1 Te 3 Hard Magnetic Nanomaterials.

Embodiment 2

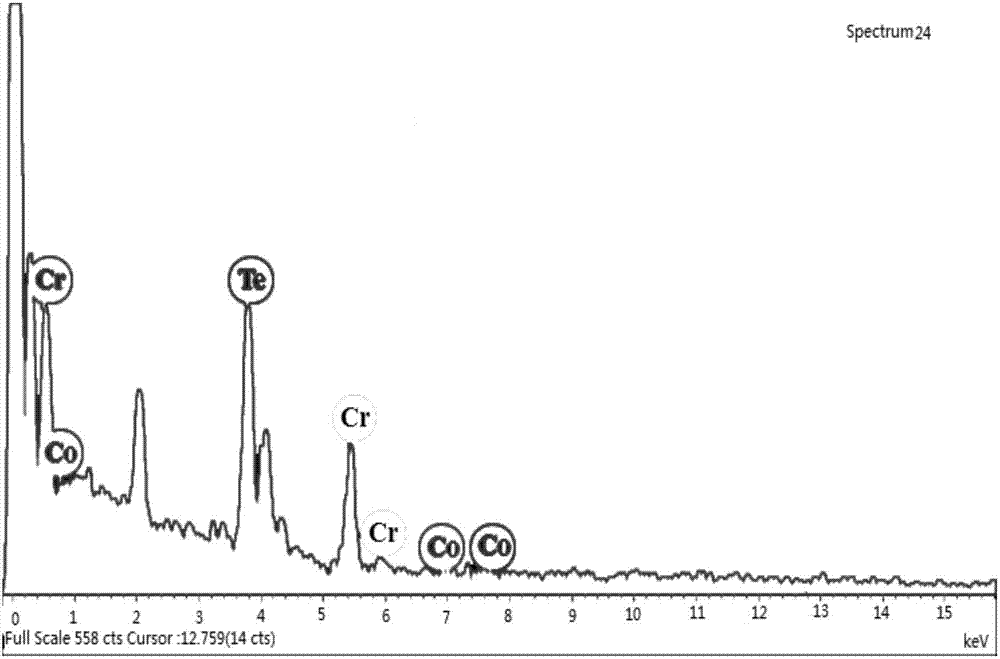

[0043]This embodiment provides a hard magnetic nanomaterial with a Cr-based chalcogen compound, which is obtained through the following preparation steps:

[0044] (1) 1.8mmol of Cr(CO) 6 , 0.2mmol of Co(acac) 2 Add oleylamine and 30mL into a four-necked flask equipped with a temperature regulator and a magnetic stirrer, stir for 20min to obtain a liquid containing Cr and Co, raise the temperature to 110°C under the protection of argon, and keep it warm for 20min;

[0045] (2) Dissolving 3.3 mmol of Te elemental powder in 5 mL of trioctyl phosphine (TOP) to obtain a suspension solution containing Te;

[0046] (3) Inject the suspension solution containing Te into the solution containing Cr and Co, raise the temperature to 380°C at a heating rate of 3°C / min under the protection of argon, and keep the reaction for 2h to obtain Cr 1.8 co 0.2 Te 3 Hard Magnetic Nanomaterials.

Embodiment 3

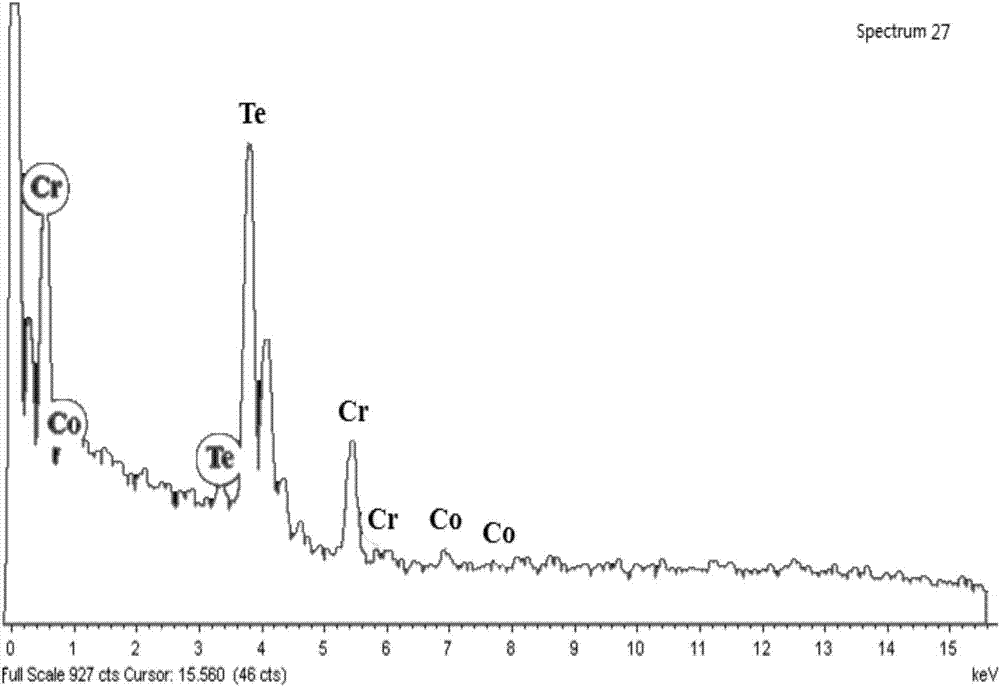

[0048] This embodiment provides a Cr-based chalcogen compound hard magnetic nanomaterial, which is obtained through the following preparation steps:

[0049] (1) 1.6mmol of Cr(CO) 6 , 0.4mmol of Co(acac) 2 and 30mL oleylamine were added into a four-necked flask equipped with a temperature regulator and a magnetic stirrer, and stirred for 30min to obtain a solution containing Cr and Co. 2 Under protection, the temperature was raised to 100°C and kept for 20 minutes;

[0050] (2) Dissolve 3.6 mmol of Te elemental powder in 5 mL of trioctyl phosphine (TOP), and sonicate for 20 min to obtain a suspension solution containing Te;

[0051] (3) Inject the suspension solution containing Te into the solution containing Cr and Co. Under the protection of nitrogen, the temperature is raised to 100°C and then the temperature is raised to 400°C at a heating rate of 2°C / min, and the temperature is kept for 3 hours to obtain Cr 1.6 co 0.4 Te 3 Hard Magnetic Nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com