Non-conducting material spark milling electrode tip

A non-conductive material and electric spark technology, applied in the field of mechanical processing, can solve the problems of poor processing environment, low processing precision, and low actual production, and achieve the effects of avoiding poor processing environment, reliable work, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

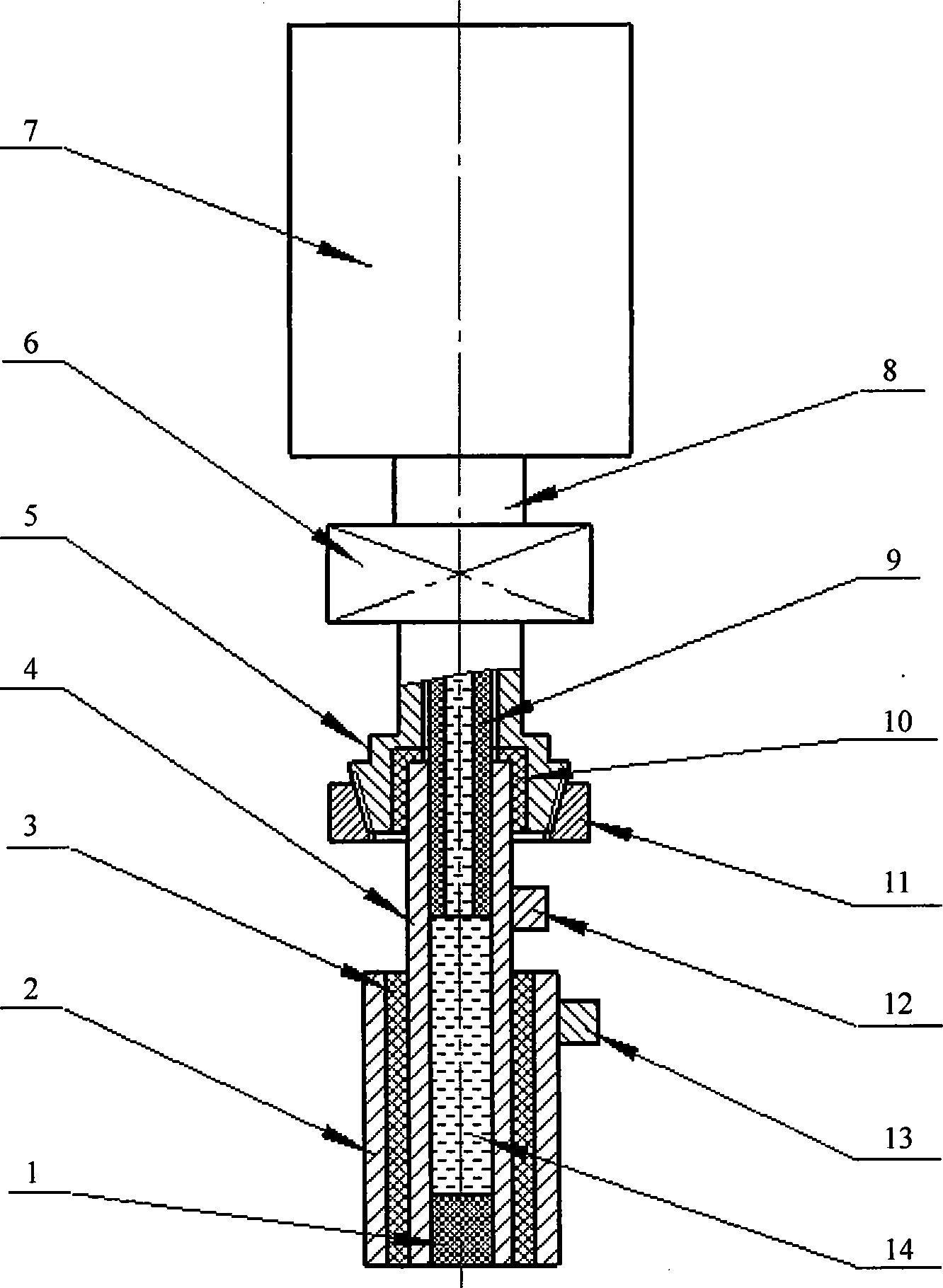

[0015] See attached picture. The electric spark milling electrode head for non-conductive material of the present invention comprises a brushing head 1, a positive tool electrode 2, an insulating spacer 3, a negative tool electrode 4, a collet 5, an electromagnetic oscillator 6, a spindle system 7, a spindle head 8, Liquid injection pipe 9, insulating jacket 10, collet lock nut 11, negative tool electrode brush 12, positive tool electrode brush 13 and water-based conductive liquid 14. The brushing head 1 brushes the conductive tuck in the inner hole of the negative tool electrode 4 on the surface of the non-conductive material workpiece to form a conductive condition on the workpiece surface; the positive tool electrode 2 is connected to the positive pole of the pulse power supply through the positive tool electrode brush 13 ; The insulating spacer 3 is used to isolate the positive and negative tool electrodes, and to consolidate them together; the negative tool electrode 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com