A Determining Method of Interfering Air Film Hole Machining Angle

A technology for processing angles and determining methods, which is applied in program control, instrumentation, computer control, etc., and can solve problems such as unfavorable interference in gas film hole processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

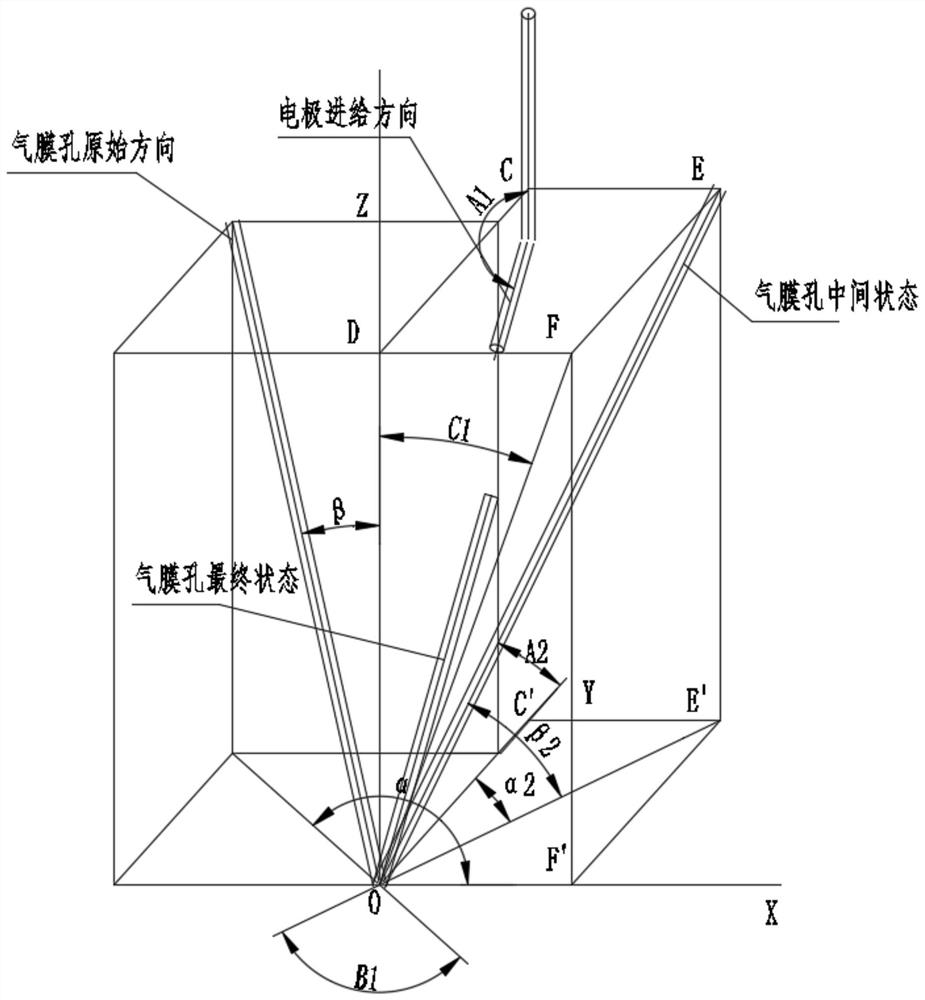

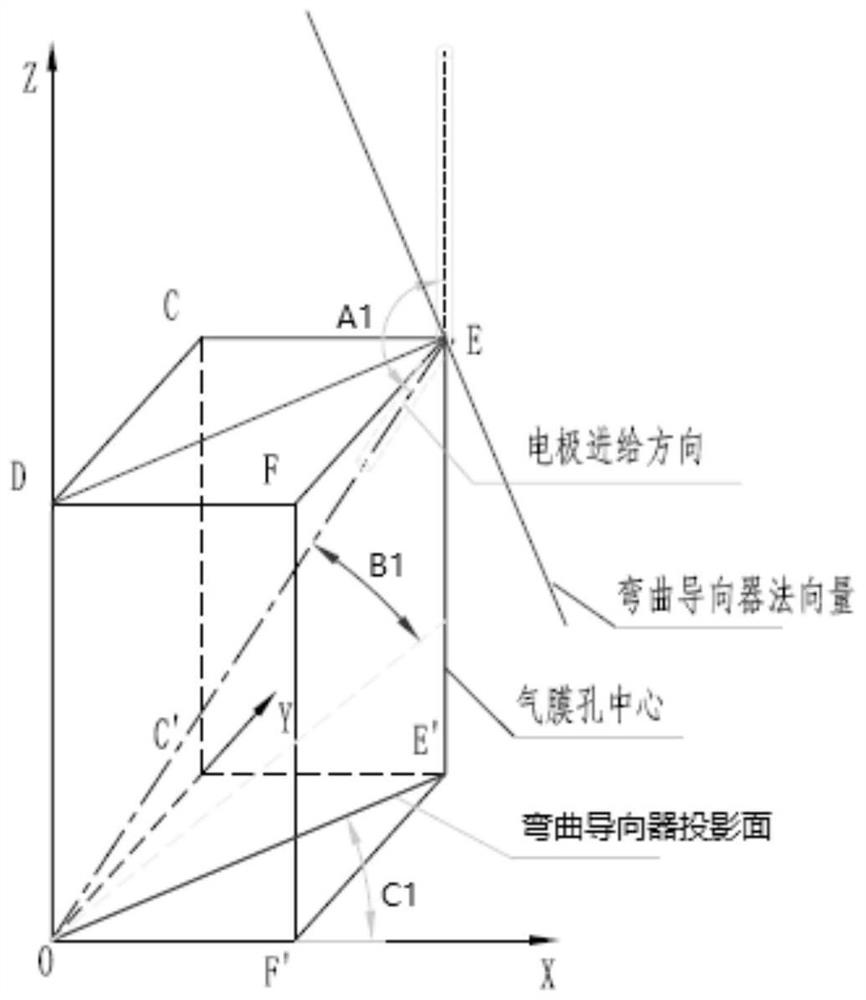

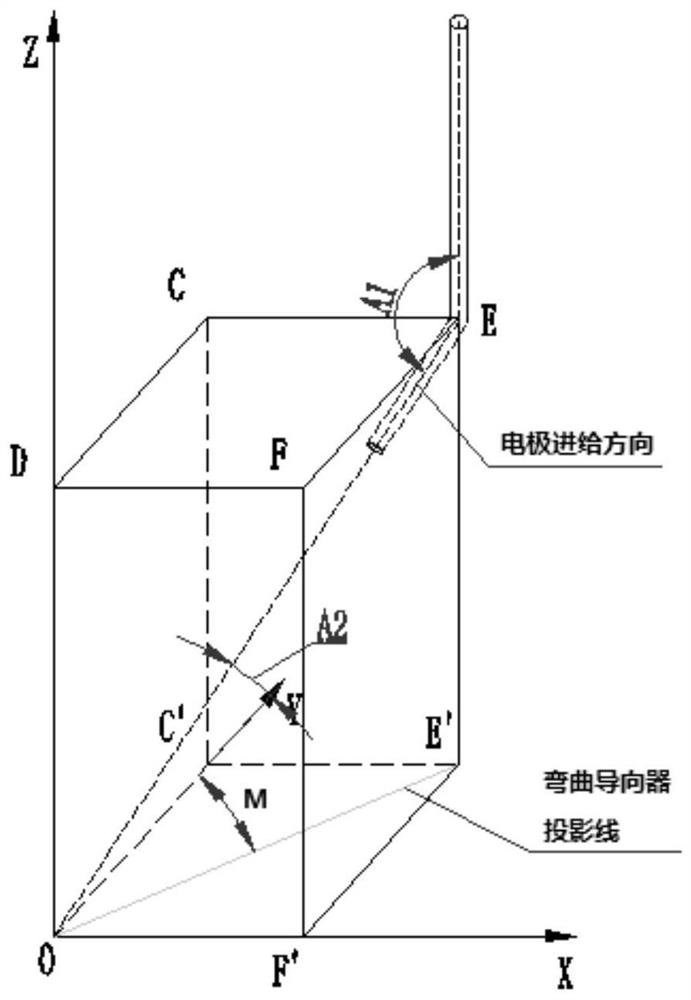

[0045] like Figure 1-Figure 4 As shown, this embodiment provides a method for determining the machining angle of the interference gas film hole.

[0046] By bending the linear guide according to a certain size and angle to form a curved guide, avoiding the interference area of the turbine guide vane blade or the mounting plate, the electrode wire can be made to spark the gas film hole along a certain curved trajectory. processing. Therefore, it is necessary to convert the machining angle of the machine tool according to the angle of the bending guide, so that it can be used for machining the interference gas film hole.

[0047] Because there is no mature product for the bending guide, it must be designed and manufactured independently. Based on design platforms such as UG software, a specific curved guide model is designed on the three-dimensional modeling of the turbine guide vane. The bending guide should not only avoid the interference between the blade body and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com