Polybutylene terephthalate fiber elastic fabric

A polybutylene terephthalate, polybutylene terephthalate technology, applied in the direction of fabrics, textiles, knitting, etc., can solve the problem of restricting the development of PBT fibers, uneven and wrinkled fabric surfaces, and poor dimensional stability. and other problems, to achieve the effect of reducing friction and irritation, smooth surface, and excellent elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

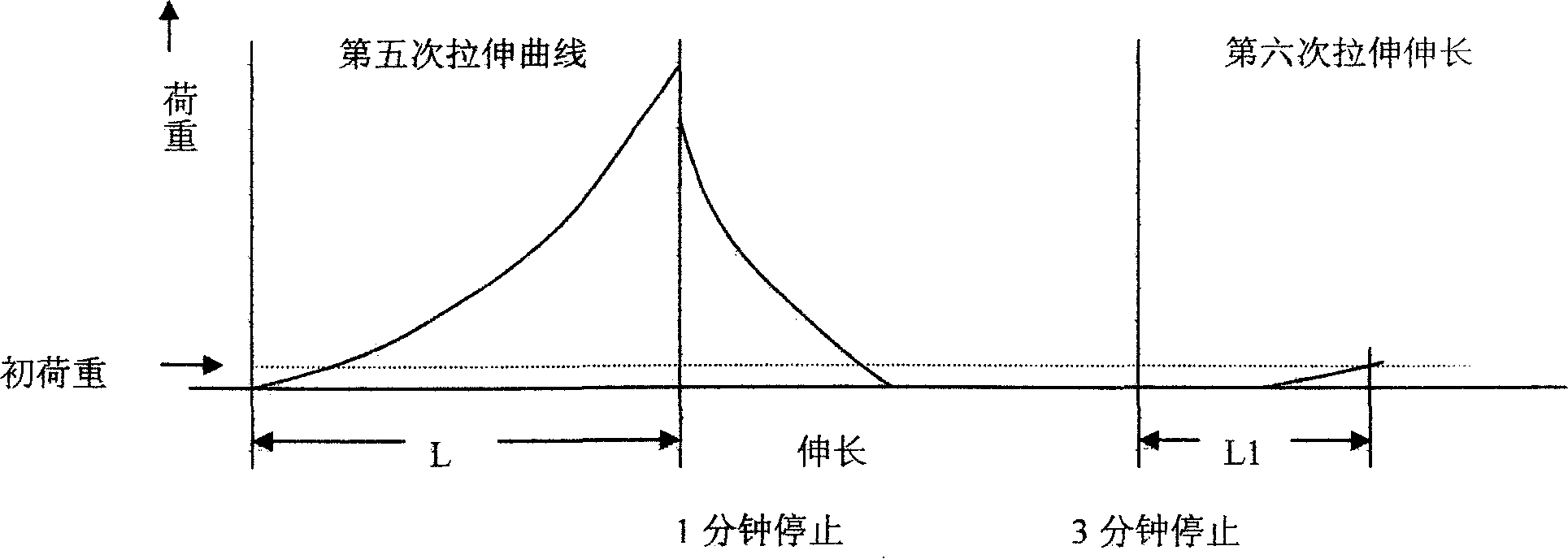

Image

Examples

Embodiment 1

[0042] 1) Yarn: warp yarn: 150D-48F-DTY (PET) interlacing number 95 pcs / m

[0043] Weft yarn: 75D-24F-PBT interlacing number 25 / m

[0044] 2) Fabric specifications and weaving

[0045] Weave: 2 / 2 Twill

[0046] Density: warp density * weft density = 100 * 82 / 2.54cm

[0047] Warp tightness: 1245, weft tightness: 710

[0048]Mixing ratio: PET / PBT=23 / 77

[0049] Weaving on an air-jet loom with 4 pieces of threading

[0050] 3) finishing method after dyeing comprises the following steps:

[0051] A. Scouring: Use 4% sodium hydroxide hot lye and soaping agent (non-cationic surfactant GQ008) to remove the size, dirt and shrink the fabric to a certain extent. The temperature is 95 degrees and the processing time is 60 seconds

[0052] B. Intermediate setting: The scouring and drying cloth is subjected to form stabilization treatment. The temperature is 180 degrees and the time is 60 seconds

[0053] C. Dyeing process: use 120 degrees down dyeing medium color, dyeing time i...

Embodiment 2

[0057] An elastic fabric of polybutylene terephthalate fiber, the warp and weft yarns that make up the fabric are polybutylene terephthalate false-twisted processed yarns, and the content of polybutylene terephthalate fiber accounts for 100% by weight; or blended yarns made of polybutylene terephthalate false-twisted processed yarn and other fibers for warp and weft, and polybutylene terephthalate fiber content accounts for 20-95% of the total fabric weight (eg 20%, 50%, 95%).

[0058] The tightness of the fabric is 700-2000 (eg 700, 1300, 2000). The monofilament fineness of polybutylene terephthalate fiber is 0.5-5.6dtex (eg 0.5dtex, 3dtex, 5.6dtex). The number of entanglements of the weft yarns is 0 to 80 / m (Example 0, 40, 80), and the number of entanglements of the warp yarns is 50 to 120 / m (Examples 50, 80, 120).

[0059] Above-mentioned fabric carries out finishing after dyeing through the same method as embodiment 1, and the modulus of elasticity of the fabric obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com