Polyamide

A polyamide and fiber technology, applied in the direction of single-component polyamide rayon, single-component copolyamide rayon, single-component synthetic polymer rayon, etc., can solve the problem of reduced solvent solubility and difficult processing Problems with forming fibers, films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0081] Hereinafter, the present invention will be described in detail through examples, but the present invention is not limited by these examples.

[0082] (1) Intrinsic viscosity of polyamide

[0083] Measured at 30°C in concentrated sulfuric acid (98% by weight) solution with a concentration of 0.5g / 100mL.

[0084] (2) Concentration of end groups

[0085] It obtained by performing proton NMR analysis on the polymer spinning dope using JEOL A-600 (600 MHz).

[0086] (3) Mechanical properties of fibers

[0087] The monofilament of the obtained fiber was subjected to a tensile test using an electronic theoretical universal testing machine 1225A manufactured by Orientec Co., Ltd., and the tensile modulus and tensile strength were determined.

reference example 1

[0088] The preparation of reference example 1 polyamide (Y)

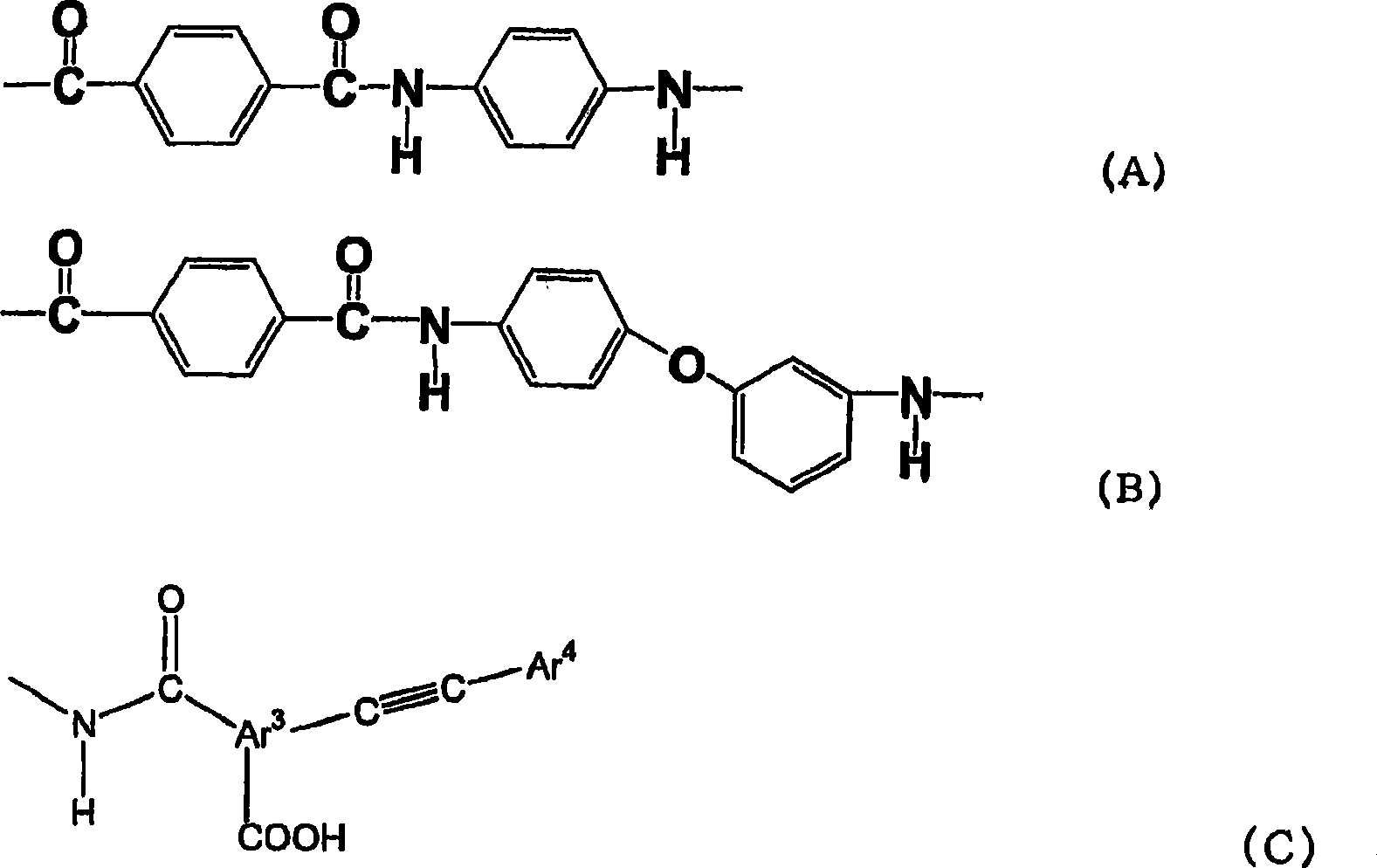

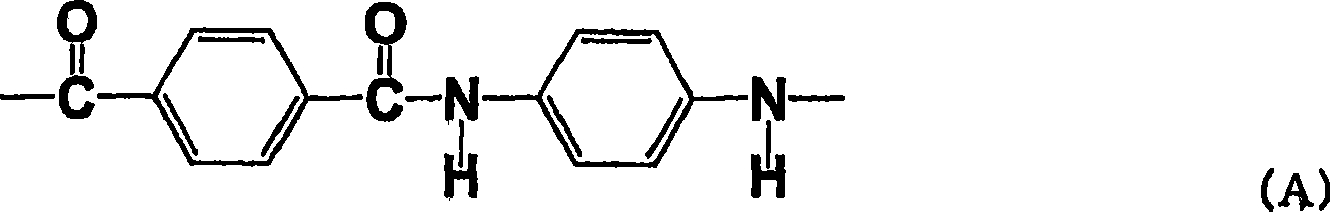

[0089] Add 2,152 parts by weight of dehydrated and purified N-methyl-2-pyrrolidone (NMP), 27.04 parts by weight of p-phenylenediamine and 50.06 parts by weight of 3,4 '-Diaminodiphenyl ether was dissolved in a nitrogen atmosphere, then it was ice-cooled, and 101.51 parts by weight of terephthalic acid dichloride was added while stirring. After that, the temperature was raised slowly, and finally reacted at 80° C. for 60 minutes. Then, 37.04 parts by weight of calcium hydroxide was added to carry out neutralization reaction to obtain a spinning dope containing polyamide (Y). In the spinning stock solution, 1,513 parts by weight of NMP were contained with respect to 100 parts by weight of polyamide (Y). A part of the spinning dope was reprecipitated with water to obtain a polyamide (Y). The intrinsic viscosity of polyamide (Y) is 3.5dL / g, and the molar ratio of (A) / (B) is 50 / 50.

Embodiment 1

[0090] Example 1 Polyamide (X) with modified end groups

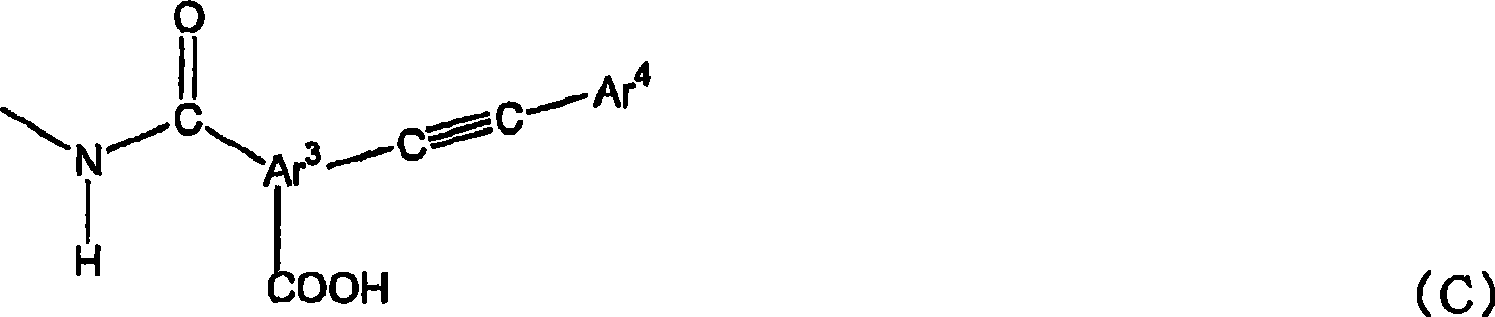

[0091] Add 210 parts by weight of dehydration-purified NMP, 5.4 parts by weight of p-phenylene diamine and 10 parts by weight of 3,4'-diaminodiphenyl ether in a fully dry three-necked flask with a stirring device at normal temperature. After dissolving under a nitrogen atmosphere, it was ice-cooled, and 20.3 parts by weight of terephthalic acid dichloride and 1.46 parts by weight of 4-phenylethynylphthalic anhydride represented by the following formula (1) were added with stirring. After that, the temperature was raised slowly, and finally reacted at 80° C. for 60 minutes, and then 7.4 parts by weight of calcium hydroxide was added for neutralization reaction to obtain a spinning dope containing polyamide (X). The spinning stock solution contained 739 parts by weight of NMP based on 100 parts by weight of polyamide (X). The spinning dope was reprecipitated with water to obtain polyamide (X). The intrinsic viscosity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com