Vortex pulp distributor

A pulp distributor and pulp outlet technology, which is applied in the field of papermaking machinery, can solve the problems of pulp pressure and flow change without a good solution, poor pulp pulse adaptability, difficulty in adapting to market demand, production conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

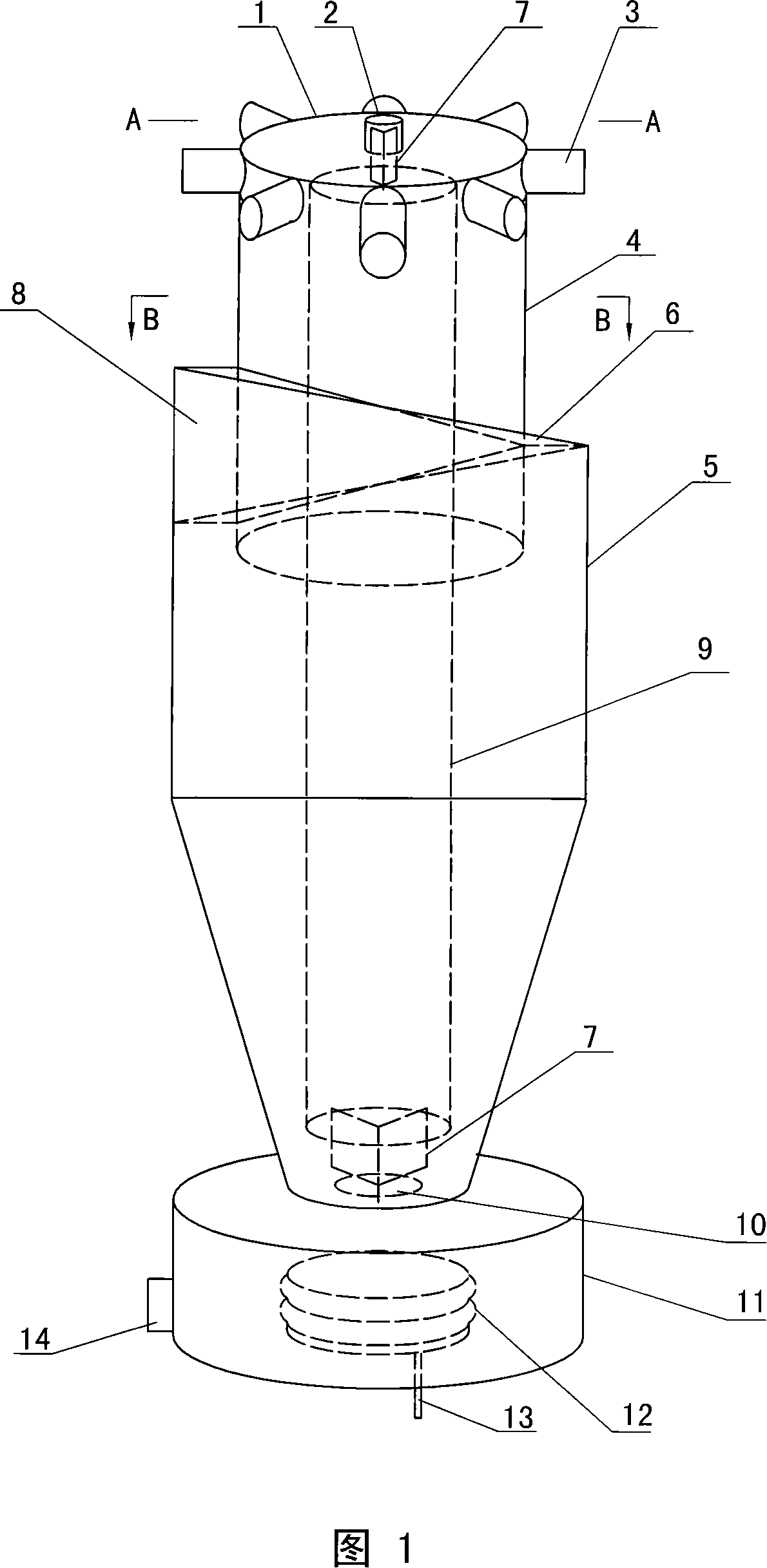

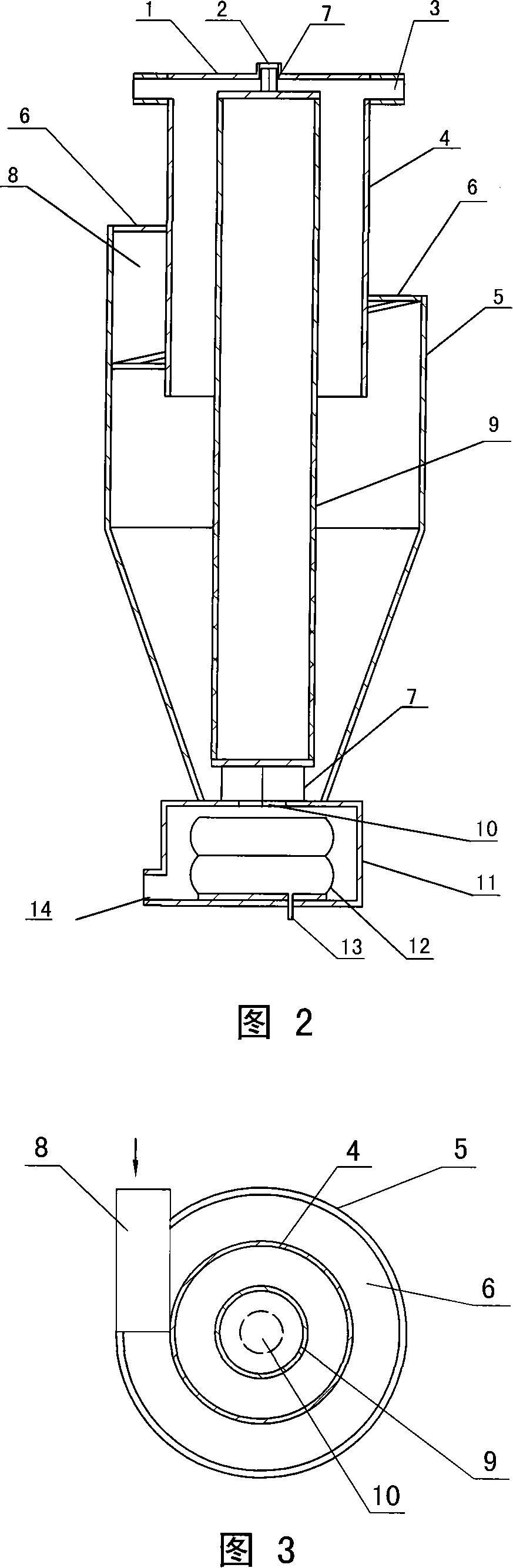

[0014] In the embodiment shown in Figures 1 to 3: the inner cylinder 4, the outer cylinder 5 and the central cylinder 9 are coaxial, the cylinder cover 1 is fixed on the top of the inner cylinder 4, and an overflow port 2 is arranged on it, and multiple pulp outlets The ports 3 are radially evenly distributed on the upper end of the inner tube 4 . The bottom of the inner cylinder 4 is horizontally open, and the outer cylinder 5 is set and fixed at the lower end of the middle part of the inner cylinder 4. The two suits form a sandwich, and the upper edge of the outer cylinder 5 is a downward spiral line, and the end of the spiral line Slightly higher than the bottom of the inner cylinder 4, the interlayer between the two cylinders is sealed by the cover plate along the helical line to form a helicoid 6, and the generation line of the helicoid 6 is perpendicular to the axis of the inner cylinder 4. The longitudinal diameter of the pulp inlet 8 is a pitch of the helix, and the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com