Bearing unit and main spindle device of machine tool provided with bearing unit

一种轴承、主轴的技术,应用在轴承元件、轴承部件的刚性支架、轴承等方向,能够解决构造复杂、成本变高、大配置空间等问题,达到简单构造、防止轴承寿命变短的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

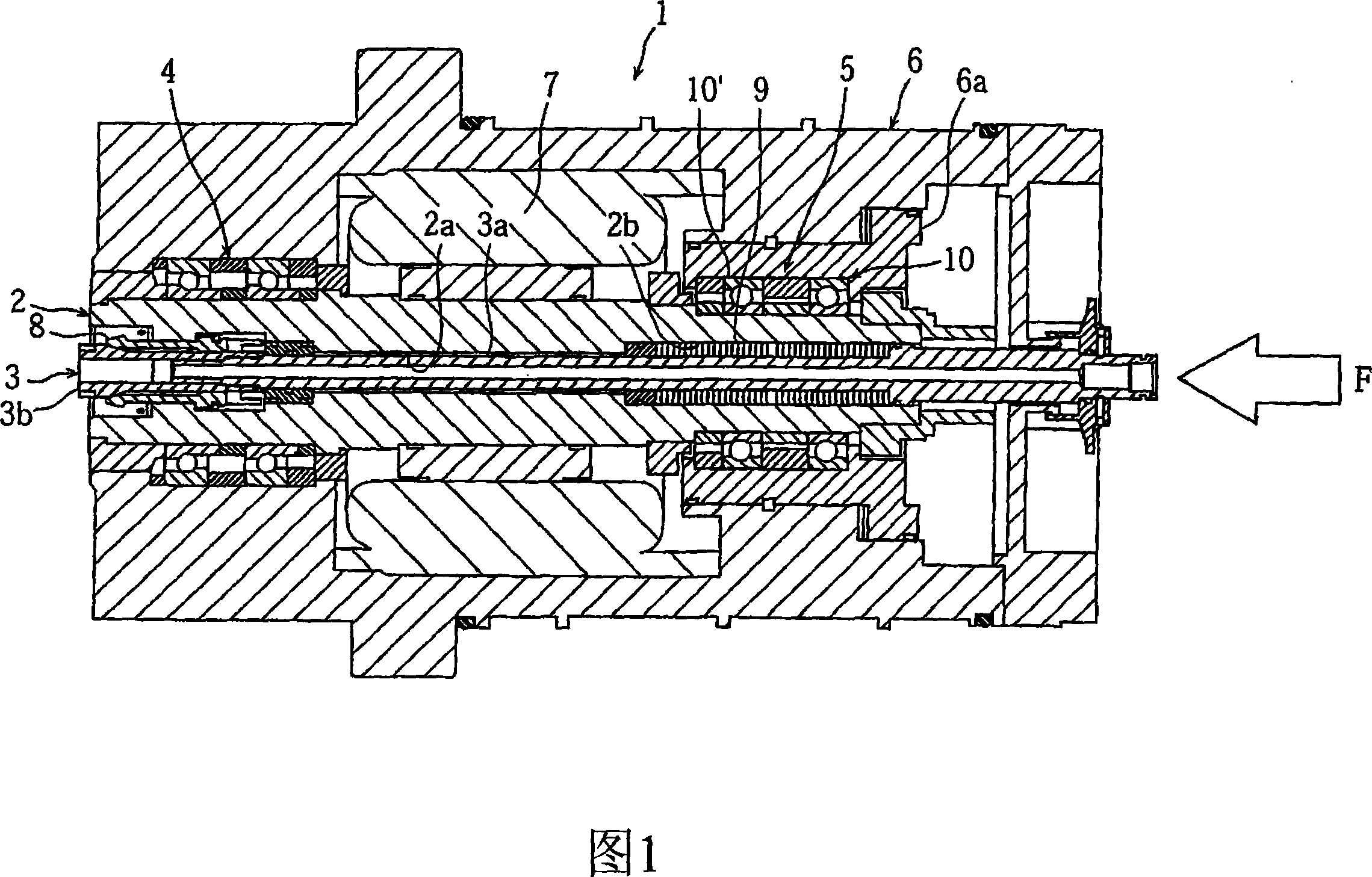

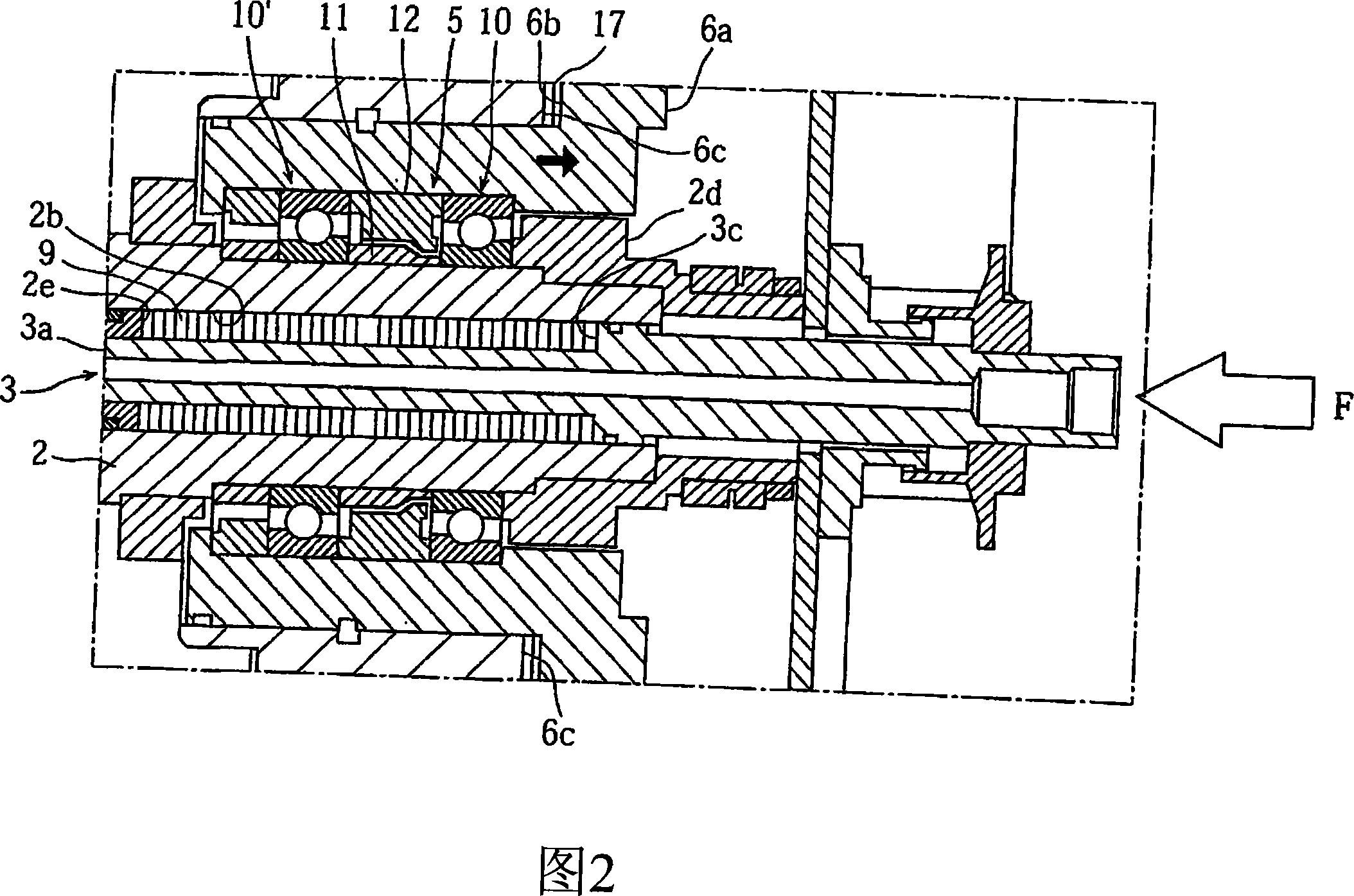

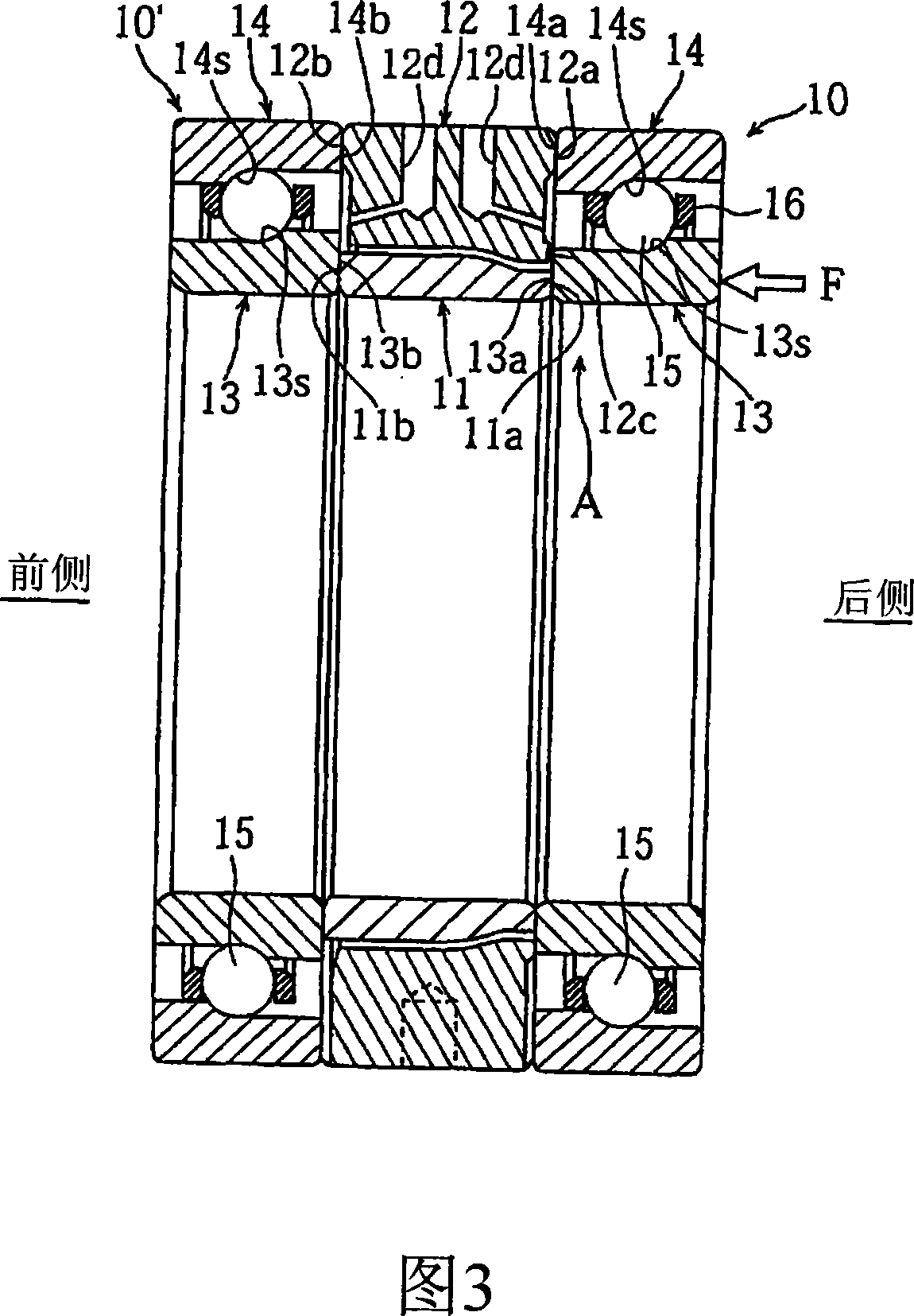

[0061] Embodiments of the present invention will be described below with reference to the drawings. 1 to 5 are views for explaining a spindle device of a machine tool including a bearing unit according to a first embodiment of the present invention.

[0062]In the figure, reference numeral 1 is a spindle device of a machine tool, and the spindle device 1 includes: a spindle 2; a draw bar unit (draw bar unit) 3 inserted into a draw bar hole 2a formed in the shaft core of the spindle 2; and a housing 6, The main shaft 2 is rotatably supported via a front bearing unit 4 and a rear bearing unit 5 . In addition, reference numeral 7 denotes a built-in spindle motor interposed between the housing 6 and the spindle 2 , and the spindle 2 is rotationally driven by the spindle motor 7 .

[0063] The tie rod unit 3 inserts a tie rod 3a into the tie rod hole 2a of the spindle 2 so as to be able to advance and retreat in the axial direction, and arranges it at the front end of the tie rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com