IC label mounting structure and IC chip for installation

一种安装结构、安装用的技术,应用在机器使用的记录载体、印刷电路、仪器等方向,能够解决耐热性低、工件加热到高温限制、基材熔化等问题,达到容易制造、安装操作容易的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

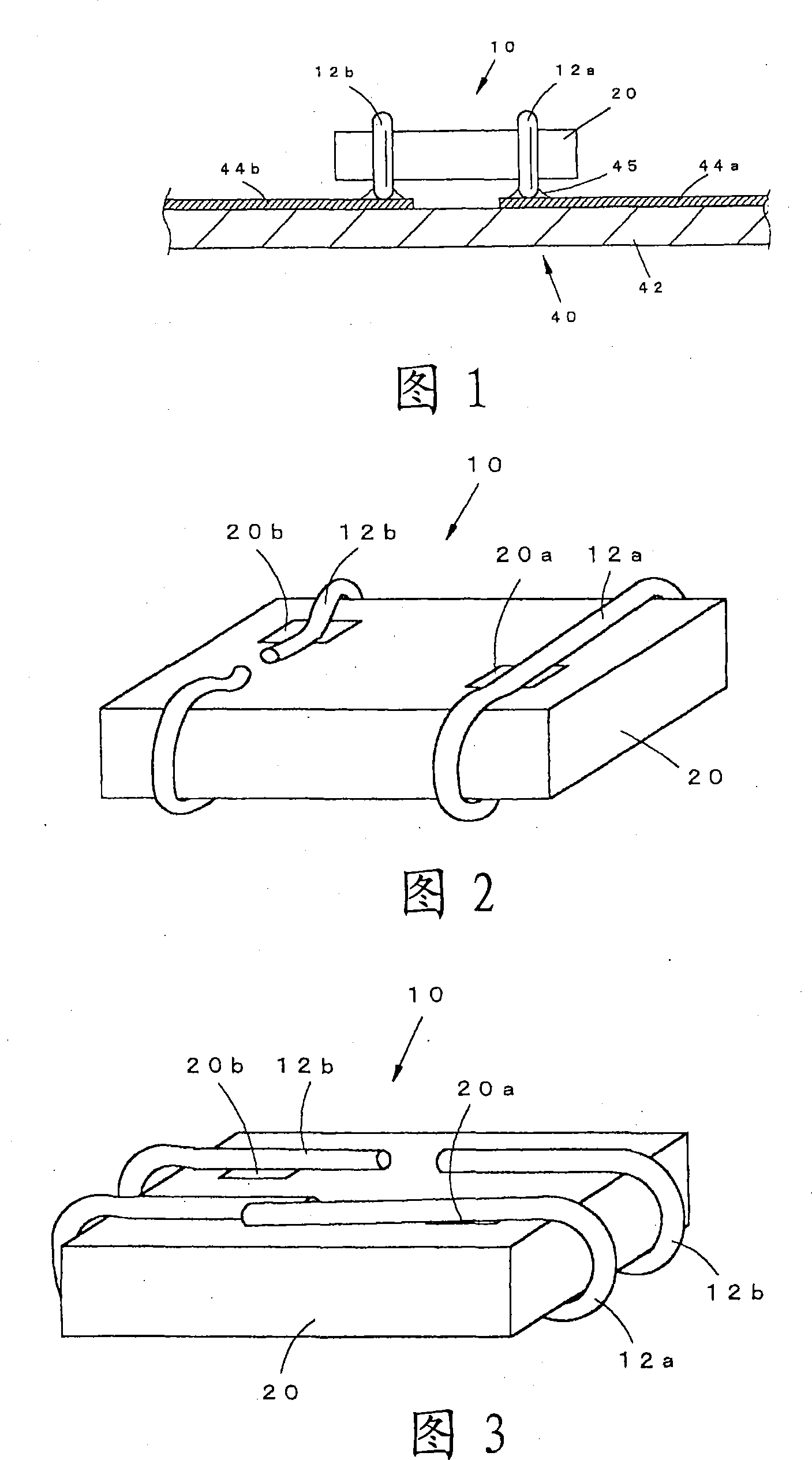

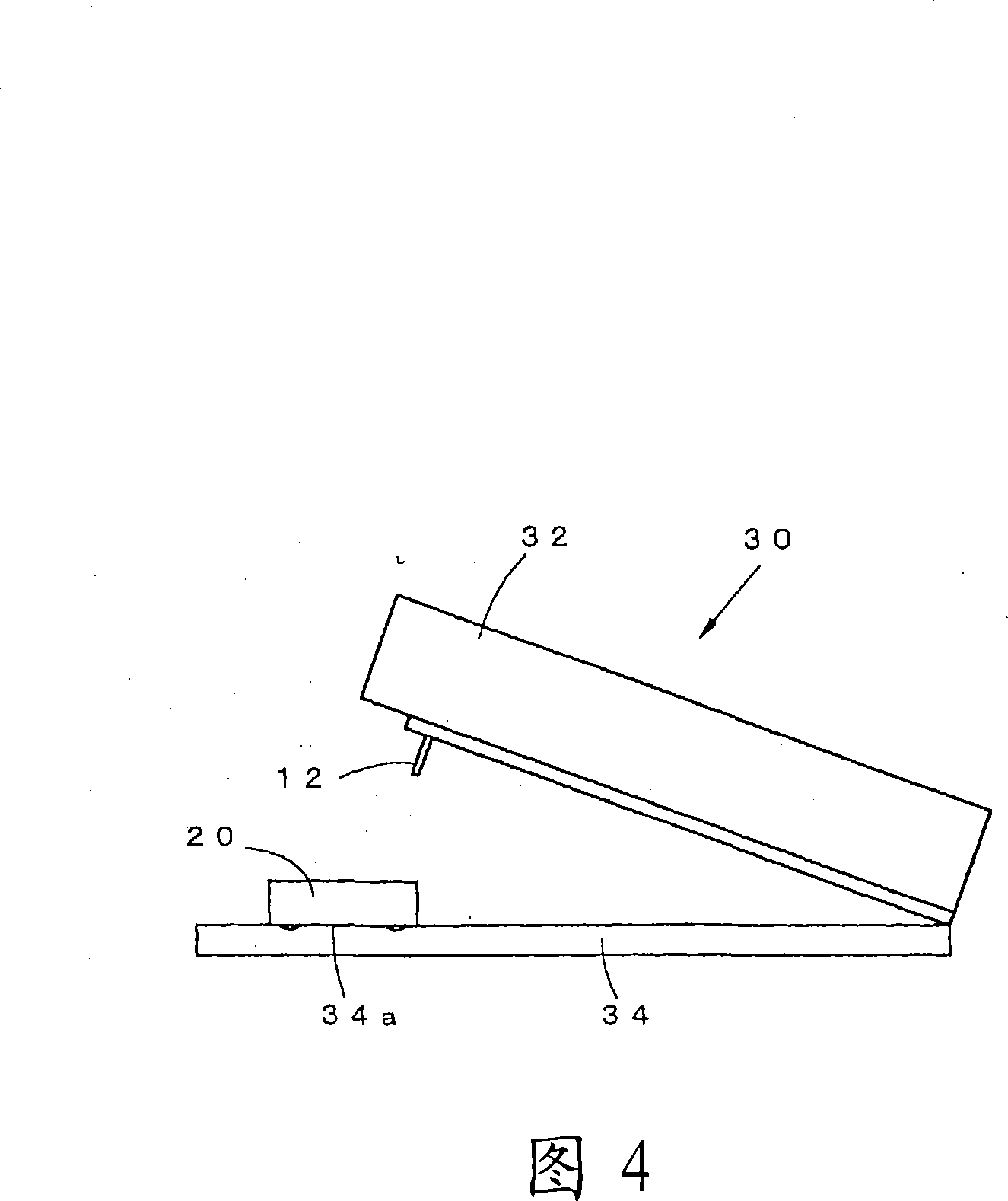

[0027] FIG. 1 is a cross-sectional view showing a first embodiment of a mounting structure of an IC tag according to the present invention. In the IC tag mounting structure of this embodiment, the IC chip 10 for mounting is electrically connected to the antenna patterns 44a and 44b formed on the front surface of the electrically insulating base film 42, and is mounted. The mounting IC chip 10 is formed by electrically connecting a pair of electrodes 20 a and 20 b formed on the IC chip 20 and winding conductive wires 12 a and 12 b around the outer surface of the IC chip 20 .

[0028] The mounting IC chip 10 is mounted on the antenna substrate 40 by connecting the conductive wires 12a, 12b wound and mounted on the IC chip 20 to the connection ends of the antenna patterns 44a, 44b with solder 45 . Thereby, the antenna patterns 44a, 44b and the IC chip 20 are electrically connected.

[0029] In addition, as a method of connecting the conductive wires 12a, 12b to the antenna patte...

no. 2 Embodiment approach

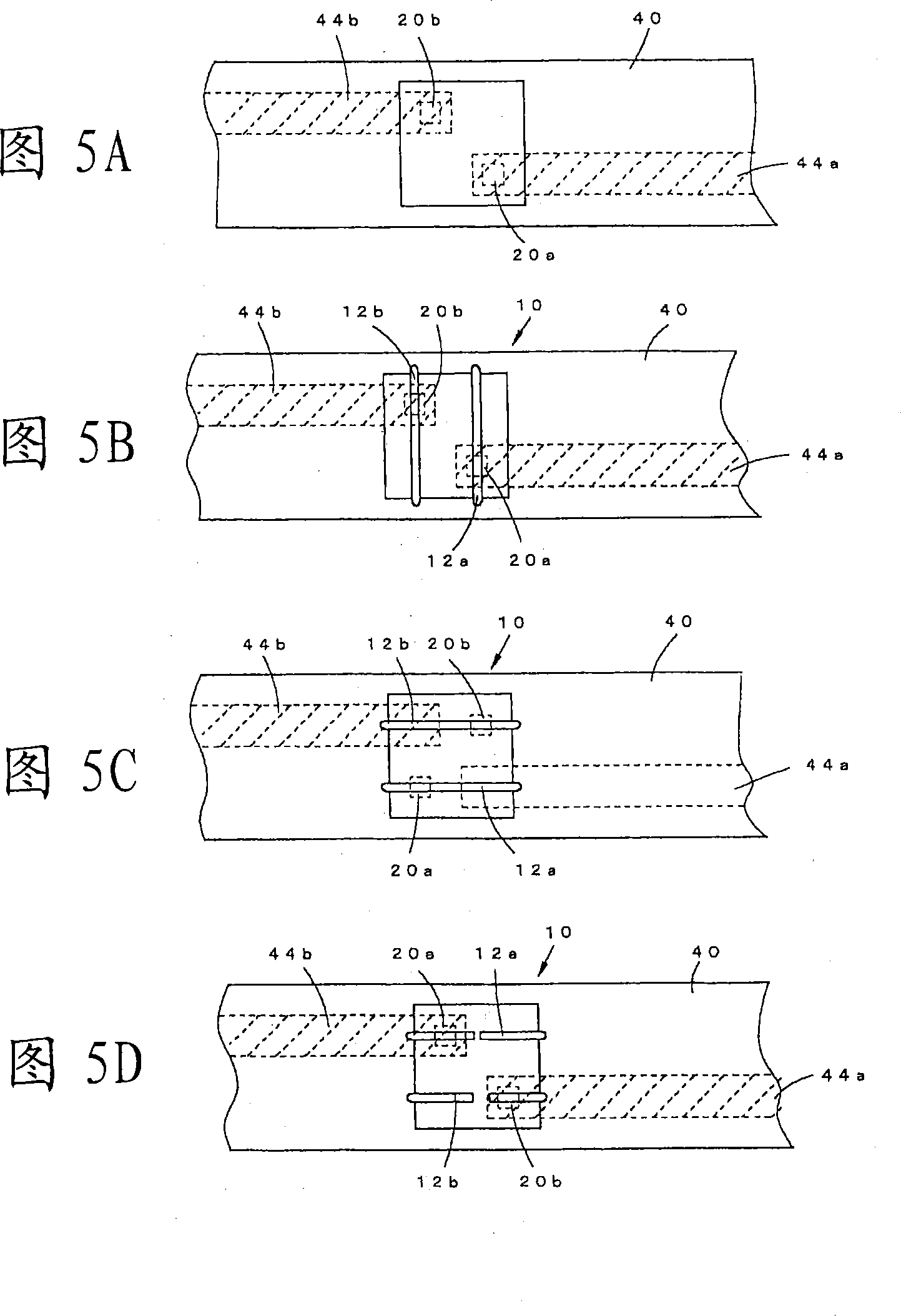

[0050] 6 is a cross-sectional view showing a second embodiment of the mounting structure of the IC tag according to the present invention. In the mounting structure of the IC tag of this embodiment, the IC chip 20 is positioned at the connection end of the antenna patterns 44a, 44b formed on the antenna substrate 40 so as to go around the outer surface of the IC chip 20 and the antenna substrate 40 together. The conductive wires 12 a and 12 b are wound in a form, and the IC chip 20 is mounted on the antenna substrate 40 .

[0051] FIG. 7 shows a winding device 35 for winding the conductive wire 12 together on the IC chip 20 and the antenna substrate 40, and the use of the winding device 35 to wind the conductive wire 12 on the IC chip 20 and the antenna substrate 40. method. The winding device 35 is formed in the same form as the stapler-shaped winding device 30 used when forming the above-mentioned IC chip 10 for mounting, and has a pressing part 36 which is accommodated in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com