Method for preparing magnetic timber

A technology for magnetic wood and wood, which is applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of complex process, high cost, poor magnetic uniformity of magnetic wood, etc., and achieves simple operation, low cost, and magnetic uniformity. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

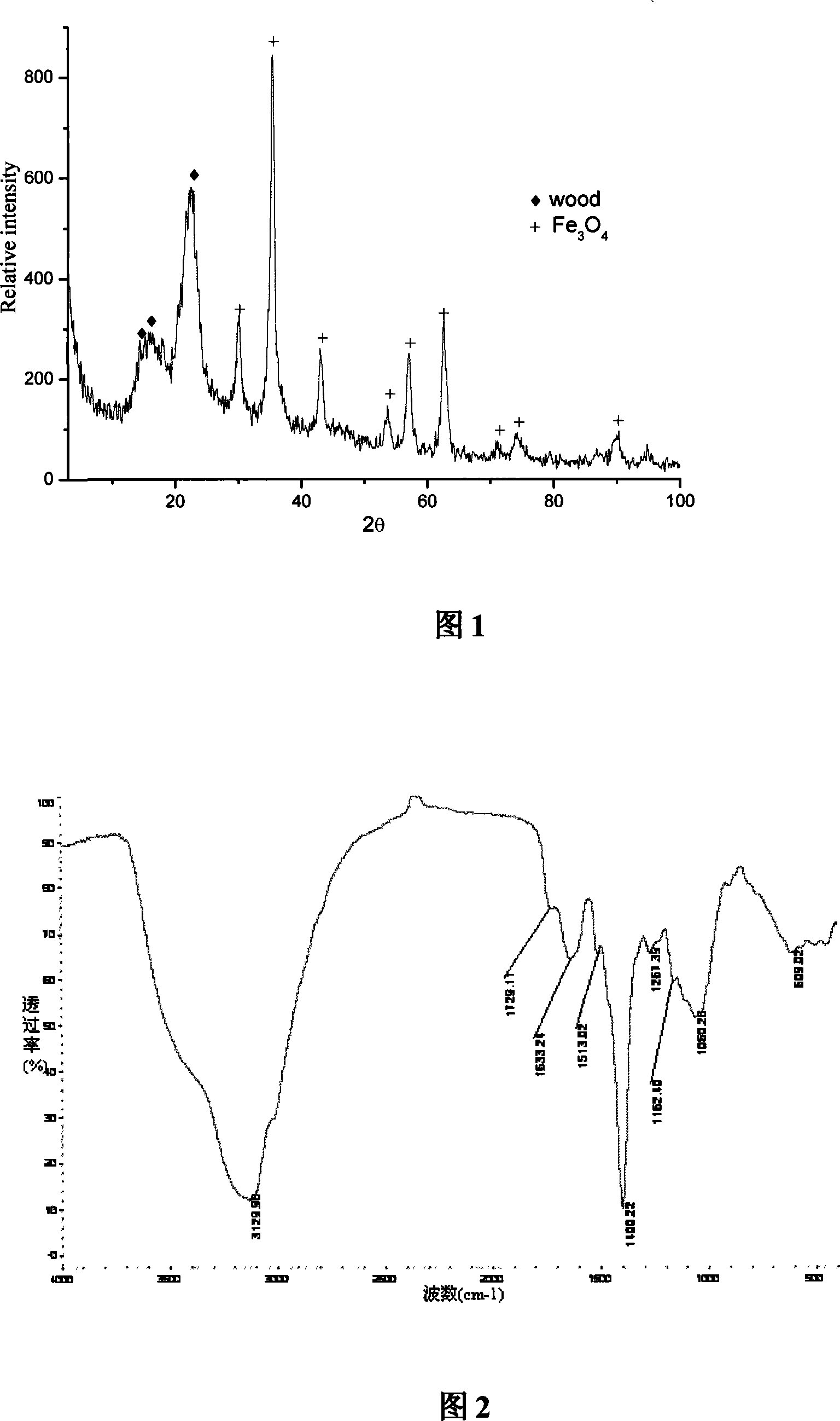

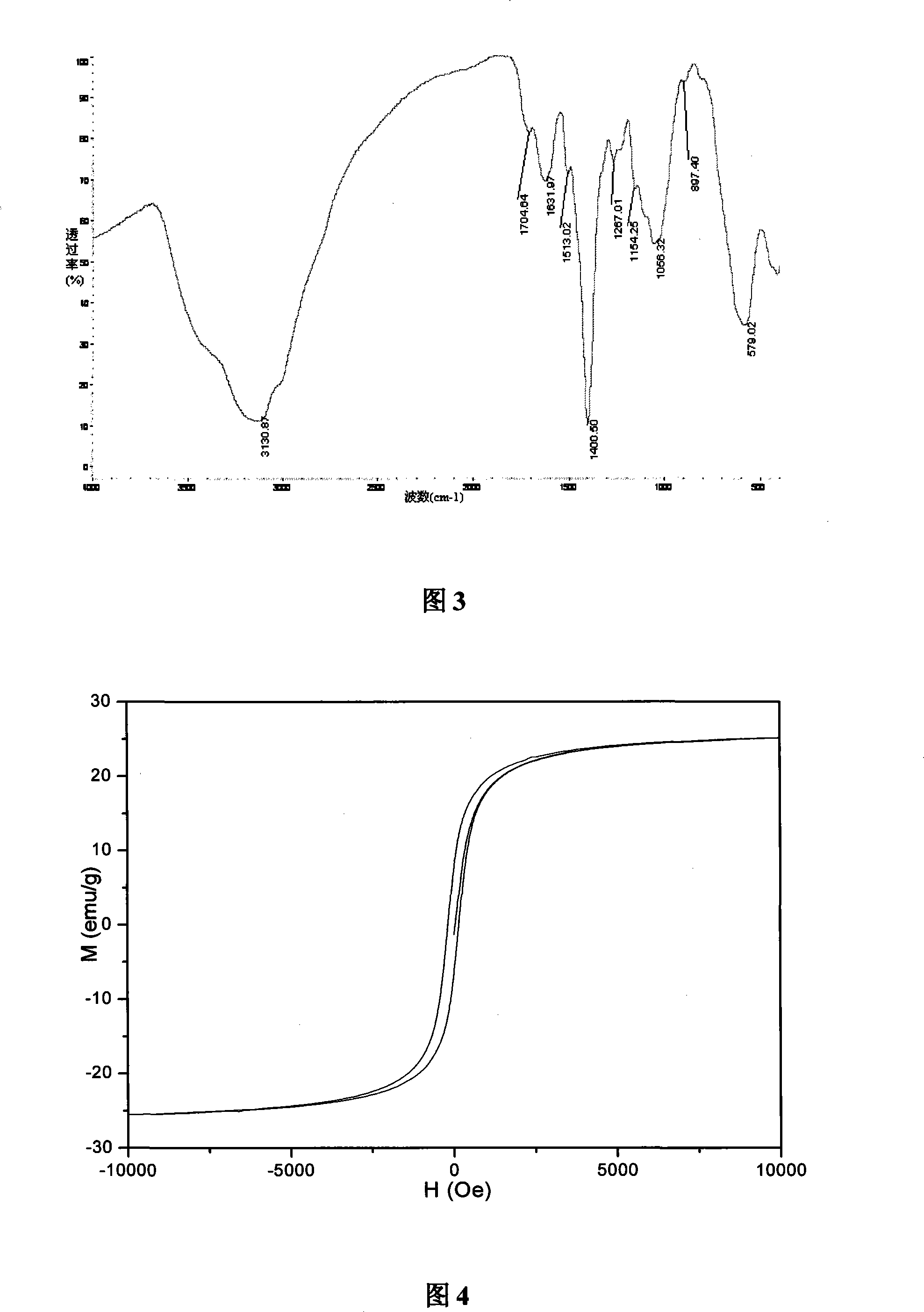

[0017] Weigh FeCl proportionally 3 and FeCl 2 Formulated as Fe 3+ and Fe 2+ The mixed iron salt solution, the total concentration of iron ions is 0.12mol / L, Fe 3+ : Fe 2+ The molar ratio of the solution is 1.2:1.0. After completely dissolving, the washed and dried Chinese fir sawdust is immersed in the solution. The immersion temperature is 30°C, the immersion pressure is 0.1MPa, and the immersion time is 3 hours. After taking out the pre-impregnated sawdust, dip it into 0.6mol / L ammonia solution for 3 hours for hydrolysis, the hydrolysis temperature is 25°C, and the hydrolysis pressure is 0.1MPa. is 0.01MPa, and the time is 12 hours, that is, the compounded Fe 3 o 4 composite sawdust.

Embodiment 2

[0019] Weigh Fe2(SO 4 ) 3 and FeSO 4 Formulated as Fe 3+ and Fe 2+ The mixed iron salt solution, the total concentration of iron ions is 1.0mol / L, Fe 3+ : Fe 2+ The molar ratio is 1.5:1.0. After completely dissolving, the washed and dried cedar wood pieces are immersed in the solution. The immersion temperature is 50°C, the immersion pressure is 1.0MPa, and the immersion time is 24 hours. After taking out the pre-impregnated wood block, dip it into 2.0mol / L ammonia solution for 24 hours and hydrolyze it for 24 hours, the hydrolysis temperature is 35°C, and the hydrolysis pressure is 0.5MPa. After taking it out, put the block into the drying device for drying, and the drying temperature is 100°C , the pressure is 0.1MPa, and the time is 10 hours, that is, the compounded Fe 3 o 4 Composite Lumber.

Embodiment 3

[0021] Weigh Fe(NO 3 ) 3 and Fe(NO 3 ) 2 Formulated as Fe 3+ and Fe 2+ The mixed iron salt solution, the total concentration of iron ions is 2.0mol / L, Fe 3+ : Fe 2+ The molar ratio is 1.8:1.0. After completely dissolving, the washed and dried red oak chips are immersed in the solution. The immersion temperature is 60°C, the immersion pressure is 1.5MPa, and the immersion time is 5 hours. After taking out the pre-impregnated wood block, dip it into 4.0mol / L ammonia solution for 5 hours for hydrolysis, the hydrolysis temperature is 30°C, and the hydrolysis pressure is 1.0MPa. After taking it out, put the block into the drying device for drying, and the drying temperature is 120°C , the pressure is 0.05MPa, and the time is 1 hour, that is, the compounded Fe 3 o 4 composite sawdust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com