Collector tube glass-metal double-port hot-pressing sealing material and method

A heat collecting tube and glass technology, which is applied in the field of vacuum heat collecting tube glass and low-expansion alloy metal double-port sealing material, can solve the problems of the vacuum heat collecting tube being unable to be completely exhausted, the exhaust temperature of the vacuum heat collecting tube being lowered, and the service life being affected. , to achieve the effect of overcoming the hardness of aluminum, solving the high probability of blowing the tube, and reducing the sealing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

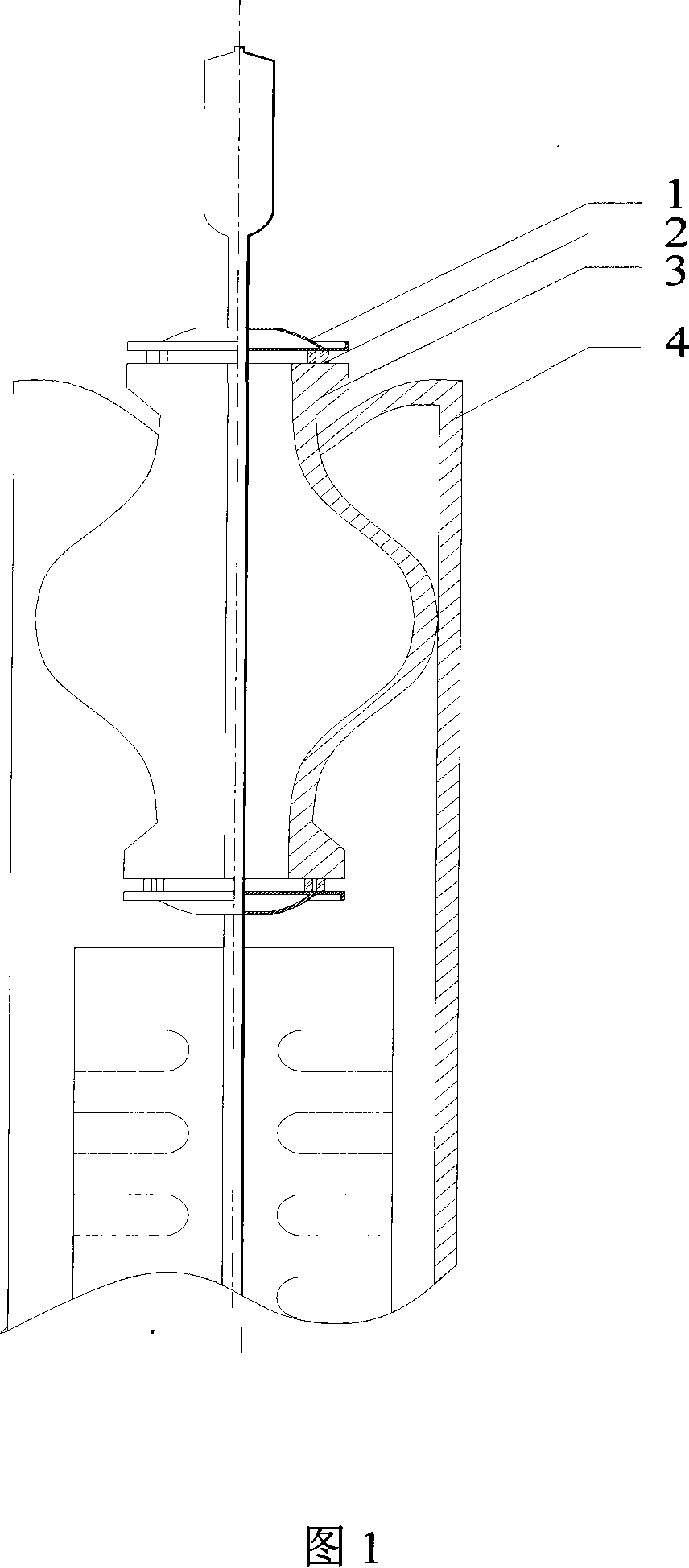

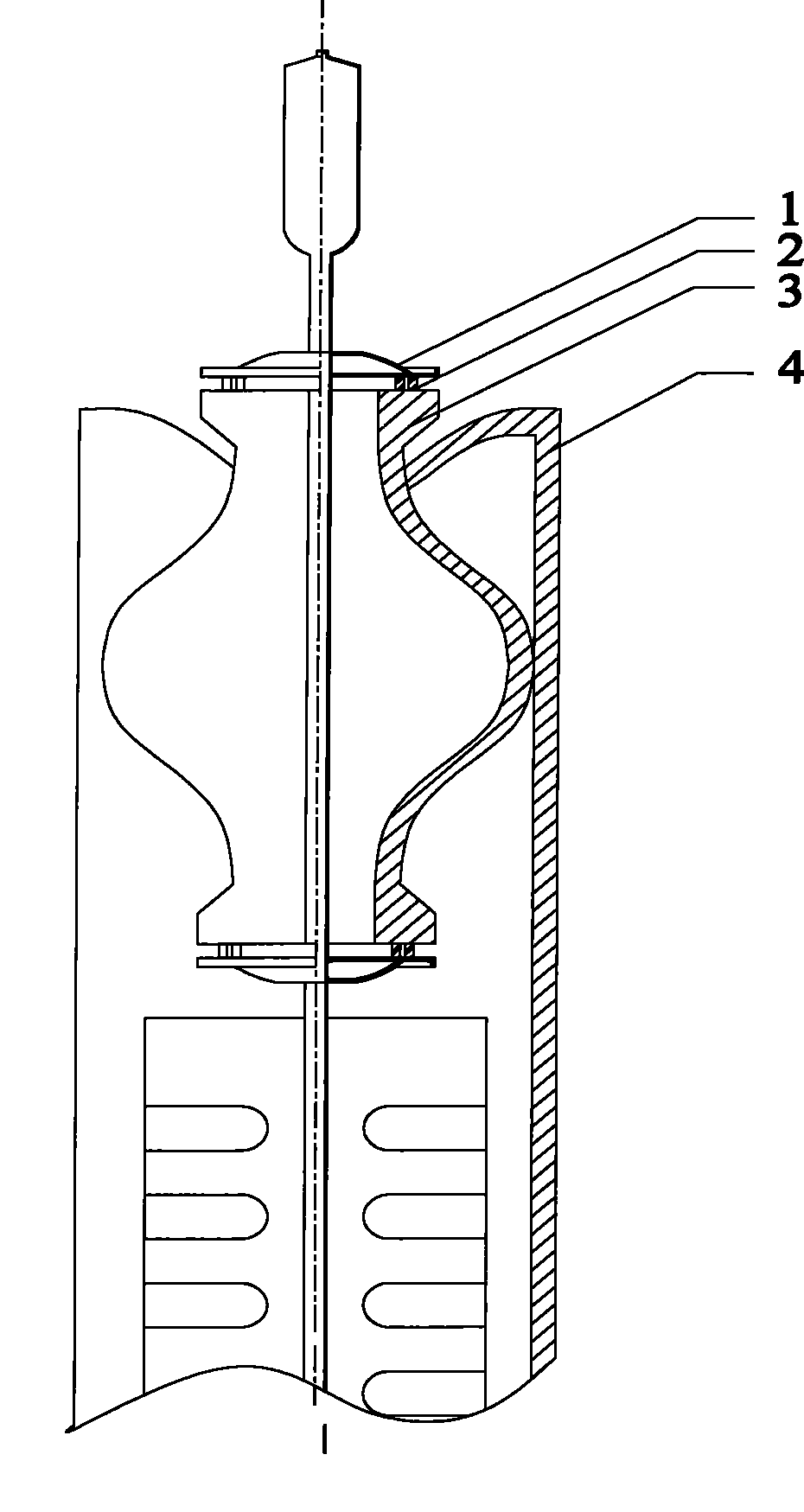

[0021] 1) The sealing part of the metal end cap 1 is mechanically cleaned (for example, rubbed with sandpaper), degreased, chemically cleaned, and the surface of the metal sealing part is dried.

[0022] 2) Alloy solder with a content of 48% lead, 42% aluminum and 10% tin is made into a φ1.0mm alloy solder wire 2, and after the alloy solder wire transition ring is installed, the top ends of a pair of arc-shaped symmetrical glass flanges 3 The metal end cover 1 on one side is positioned with the corresponding glass flange 3 on the upper side. The diameter of the glass flange 3 is φ70mm, and the expansion coefficient of the glass flange 3 and the heat-collecting glass tube 4 is 3.4×10 -6 / °C.

[0023] 3) After the metal end cap sealing part 1 and the glass flange 3 are positioned, the alloy solder ring 2 is heated to 355°C in a hot-press sealing machine, and the sealing temperature is 0.7 times the melting point of the alloy metal solder. Within the annealing temperature, apply...

Embodiment 2

[0027] 1) The sealing part 1 of the metal end cap is mechanically cleaned (for example, rubbed with sandpaper), degreased, chemically cleaned, and the surface of the metal sealing part is dried.

[0028] 2) Make solder wire with a content of 49% lead, 42% aluminum and 9% tin into a solder wire with a diameter of 1.5mm. The metal end cover 1 and the corresponding upper side glass flange 3 are positioned, the diameter of the glass flange 3 is φ70mm, and the expansion coefficient of the glass flange 3 and the heat collecting glass tube 4 is 3.3×10 -6 / °C.

[0029] 3) After the metal end cover sealing part 1 and the glass flange 3 are positioned, the alloy solder ring 2 is heated to 365-370°C in a hot-press sealing machine, and the sealing temperature is 0.9 times the melting point of the alloy metal solder. Within the annealing temperature of the solder wire, apply 190kg / cm to the end face 2 The impact pressure is 5s, and the metal end cap 1 and the glass flange 3 on the top si...

Embodiment 3

[0033] 1) The sealing part 1 of the metal end cap is mechanically cleaned (for example, rubbed with sandpaper), degreased, chemically cleaned, and the surface of the metal sealing part is dried.

[0034] 2) Make solder wire with a content of 50% lead, 40% aluminum and 10% tin into a solder wire of φ1.5mm. The metal end cover 1 and the corresponding upper side glass flange 3 are positioned, the diameter of the glass flange 3 is φ70mm, and the expansion coefficient of the glass flange 3 and the heat collecting glass tube 4 is 3.3×10 -6 / °C.

[0035] 3) After the metal end cap sealing part 1 and the glass flange 3 are positioned, the alloy solder ring 2 is heated to 360°C in a hot-press sealing machine, and the sealing temperature is 0.8 times the melting point of the alloy metal solder. Within the annealing temperature, apply 170kg / cm to the end face 2 The impact pressure is 10s, and the metal end cap 1 and the glass flange 3 on the top side of the symmetrical sealing structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com