Hot rolling bar plate scythes bend and bias-running online detection method

A sickle bend and slab technology, applied in heat treatment furnaces, measuring devices, heat treatment equipment, etc., can solve problems such as difficulty in obtaining accurate data, deviation of slabs, and difficult handling. The method is practical and simple, easy to operate, and Implement a noticeable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

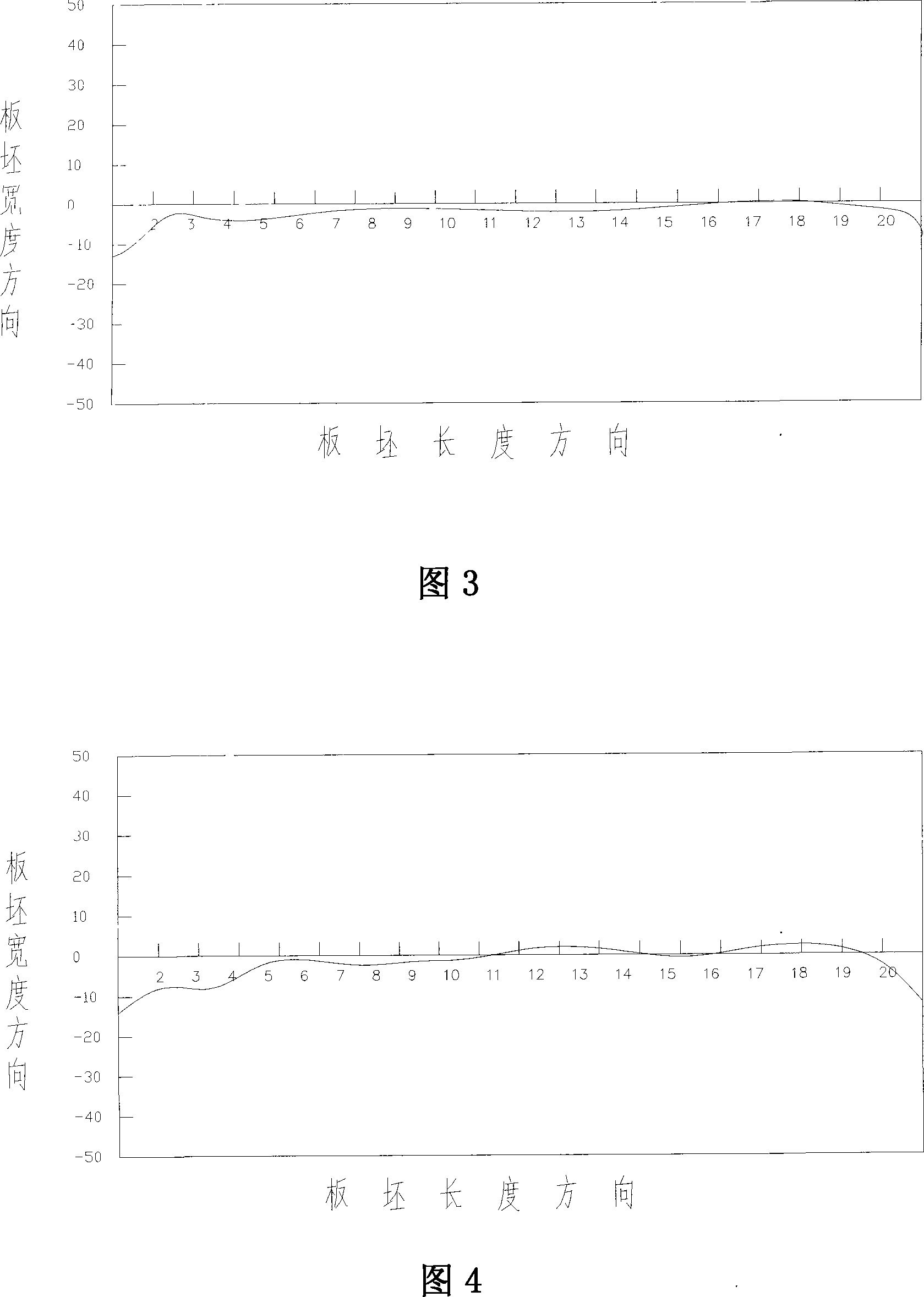

[0028] Heating furnace type: CSP roller hearth soaking furnace; furnace length: 191.8m

[0029] Process parameters: slab width: 1125mm; slab thickness: 55mm; head in furnace time: 1210s; head heating time: 740s; tail in furnace time 700s; tail heating time 420s.

[0030] The slab results measured on the basis of the above are shown in Figure 3.

Embodiment 2

[0032] Heating furnace type: CSP roller hearth soaking furnace; furnace length: 191.8m

[0033] Process parameters: slab width: 1180mm; slab thickness: 55mm; head in furnace time: 1200s; head heating time: 700s; tail in furnace time 710s; tail heating time 430s.

[0034] The slab results measured on the basis of the above are shown in Figure 4.

Embodiment 3

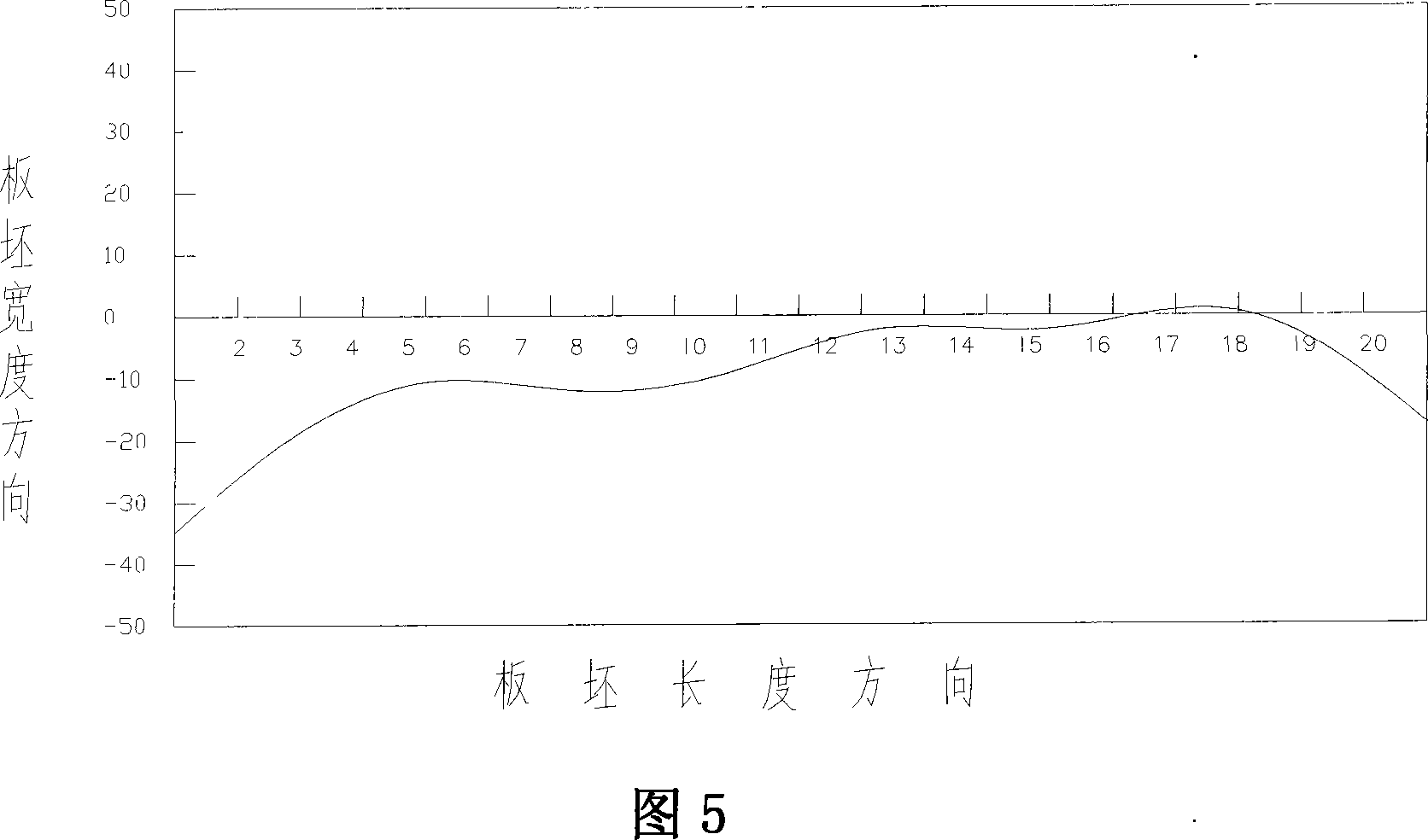

[0036] Heating furnace type: CSP roller hearth soaking furnace; furnace length: 191.8m

[0037] Process parameters: slab width: 1250mm; slab thickness: 55mm; head in furnace time: 1220s; head heating time: 730s; tail in furnace time 710s; tail heating time 430s.

[0038] The slab results measured on the basis of the above are shown in Figure 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com