Device for folding and bolding plastic-laminated pre-cut blanks

A technology of plastic layers and blanks, applied in the field of devices for folding and combining plastic laminated pre-cut blanks, which can solve problems such as combustion furnace deformation, overheating, and system complexity, and achieve the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

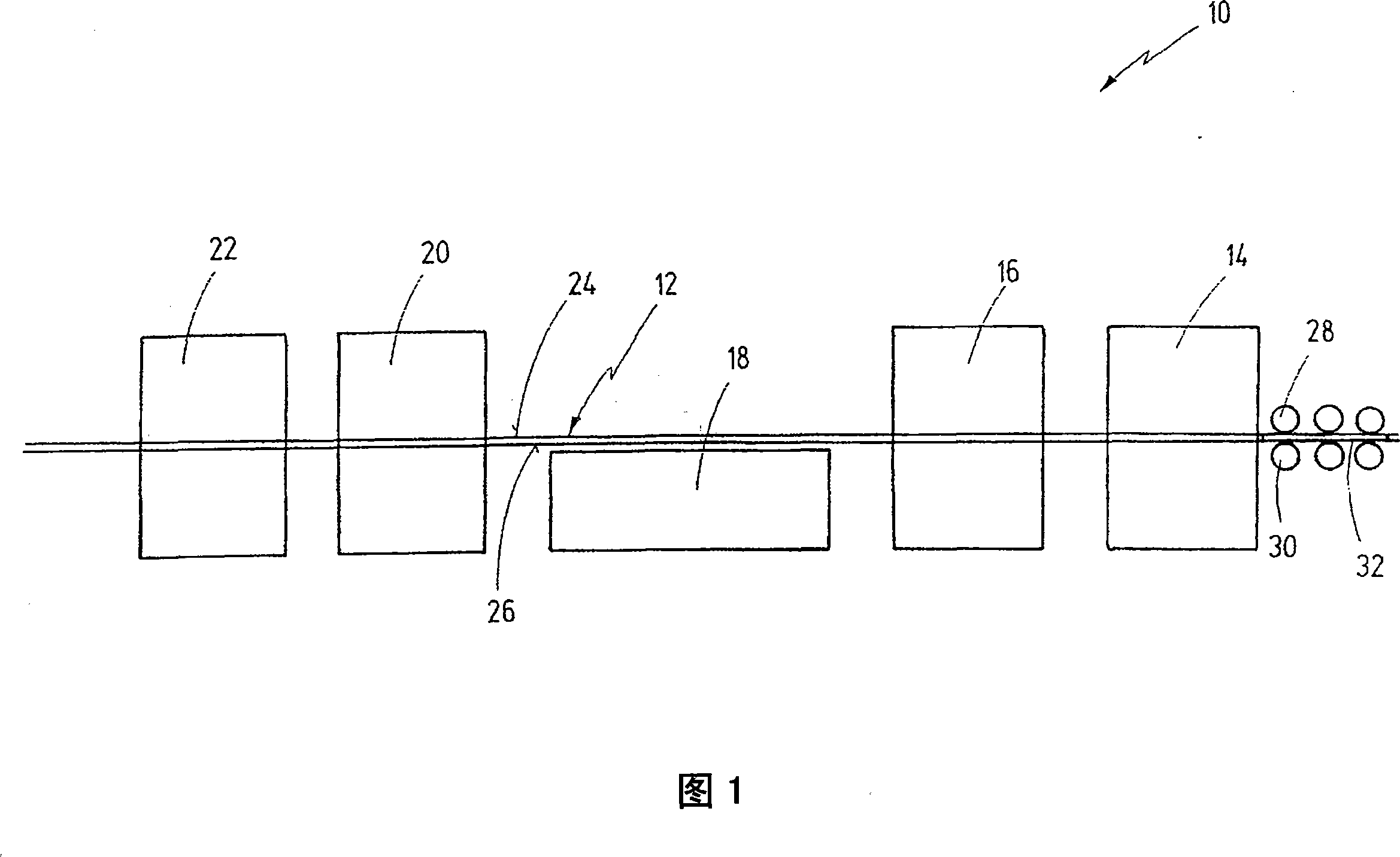

[0049] An apparatus for folding and bonding plastic laminated pre-cut blanks according to the invention is shown schematically in FIG. 1 and is indicated generally by the reference numeral 10 .

[0050] The pre-cut blanks 32 are PE-laminated paperboard blanks which are folded and joined to make beverage packaging. The sides of the blank (which later form the inside of the package to be manufactured) are all coated with a thin layer of polyethylene coating. The blanks 32 are conveyed by the conveying device 12 through the different work stations 14 , 16 , 18 , 20 , 22 of the device 10 at a transit speed of several hundred meters per minute or even approximately 1000 meters per minute. The conveyor 12 includes belts 24, 26 driven by rollers 28, 30 for moving batches therebetween. In FIG. 1 , only a few rollers 28 are schematically shown above the conveyor belt 24 only at the entrance of the device 10 , and a few rollers 30 are schematically shown below the conveyor belt 26 . H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com