Anaerobic-anoxic oxidation pitch technique denitrification dephosphorization device and method

A technology of denitrification phosphorus removal and oxidation ditch, applied in the field of biological nitrogen and phosphorus removal of domestic sewage, can solve the problems of low phosphorus removal efficiency, achieve the effect of increasing pH value, saving aeration energy consumption, and stabilizing biological phosphorus removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

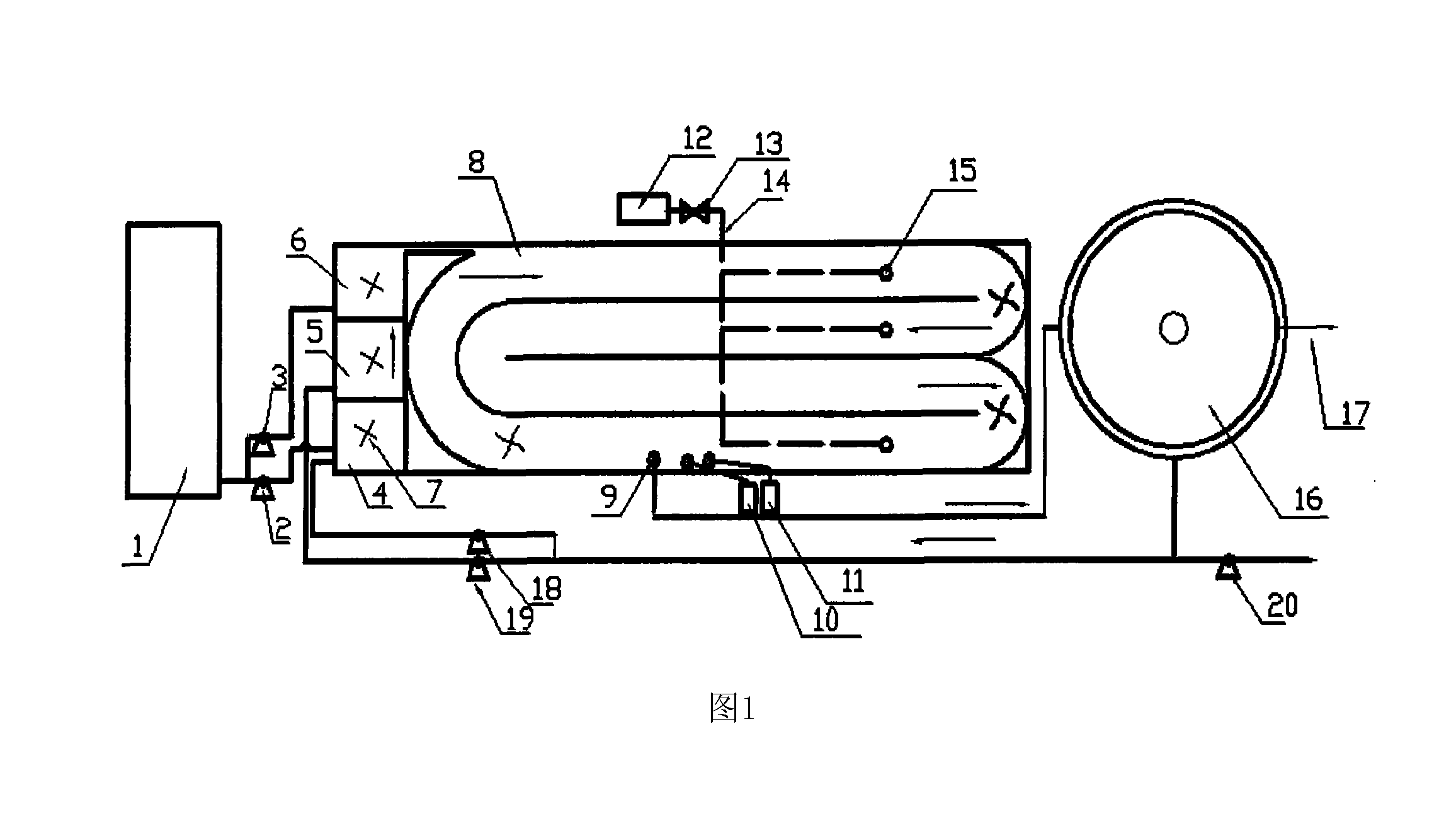

[0032] The inoculated sludge was from the return sludge of Beijing Jiuxianqiao Sewage Treatment Plant, and the test water was taken from the aerated grit chamber of Beijing Jiuxianqiao Sewage Treatment Plant. The main water quality indicators in the experimental stage are: COD is 232 ~ 621mg / L, NH 4 + 42.1~64.5mg / L, PO 4 3-It is 5.2-9.1 mg / L, TP is 5.9-9.7 mg / L, TN is 56.4-73.5 mg / L, pH is 7.2-7.8. The analytical methods used in the experiments were in accordance with the standard methods issued by the State Environmental Protection Administration.

[0033] The test steps are to add the inoculated sludge into the aeration tank 8, put the domestic sewage into the water tank 1, start the inlet pump A2 and the inlet pump B3, and 70-80% of the raw sewage and 25-50% of the return sludge are in the tank. Mixed by agitator 7 in anaerobic tank 4, a small amount of NO in sludge is returned 3 - It is quickly removed by denitrification by heterotrophic bacteria, and phosphorus accu...

specific Embodiment 2

[0035] The inoculated sludge was from the return sludge of the Jiuxianqiao Sewage Treatment Plant in Beijing, and the test water was taken from the domestic sewage of the municipal pipeline of the Family Pool of Beijing University of Technology. The main water quality indicators are: COD is 201 ~ 532mg / L, NH 4 + 47.5 / 61.9mg / L, PO 4 3- was 3.4 / 8.6 mg / L, TN was 52.4 / 68.3 mg / L, and pH was 7.2 / 7.8. The analytical methods used in the experiments were in accordance with the standard methods issued by the State Environmental Protection Administration.

[0036] The test procedure is to add the inoculated sludge into the aeration tank 8, put the domestic sewage into the water tank 1, start the inlet water pump A2 and the inlet water pump B3, and the water inlet ratio of the inlet water pumps A2 and B3 is 4:1, and at the same time, the backflow is turned on. The flow ratio of sludge pumps A18 and B19 and return sludge pumps A18 and B19 is 1:3. Through continuous treatment of domesti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com