Yarn cold rolling batch-dying process

A cold pad-batch dyeing and yarn technology, applied in the field of yarn dyeing, can solve the problems of high energy consumption, large investment in equipment, heavy pollution, etc., and achieve the effect of good dyeing fastness, small investment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

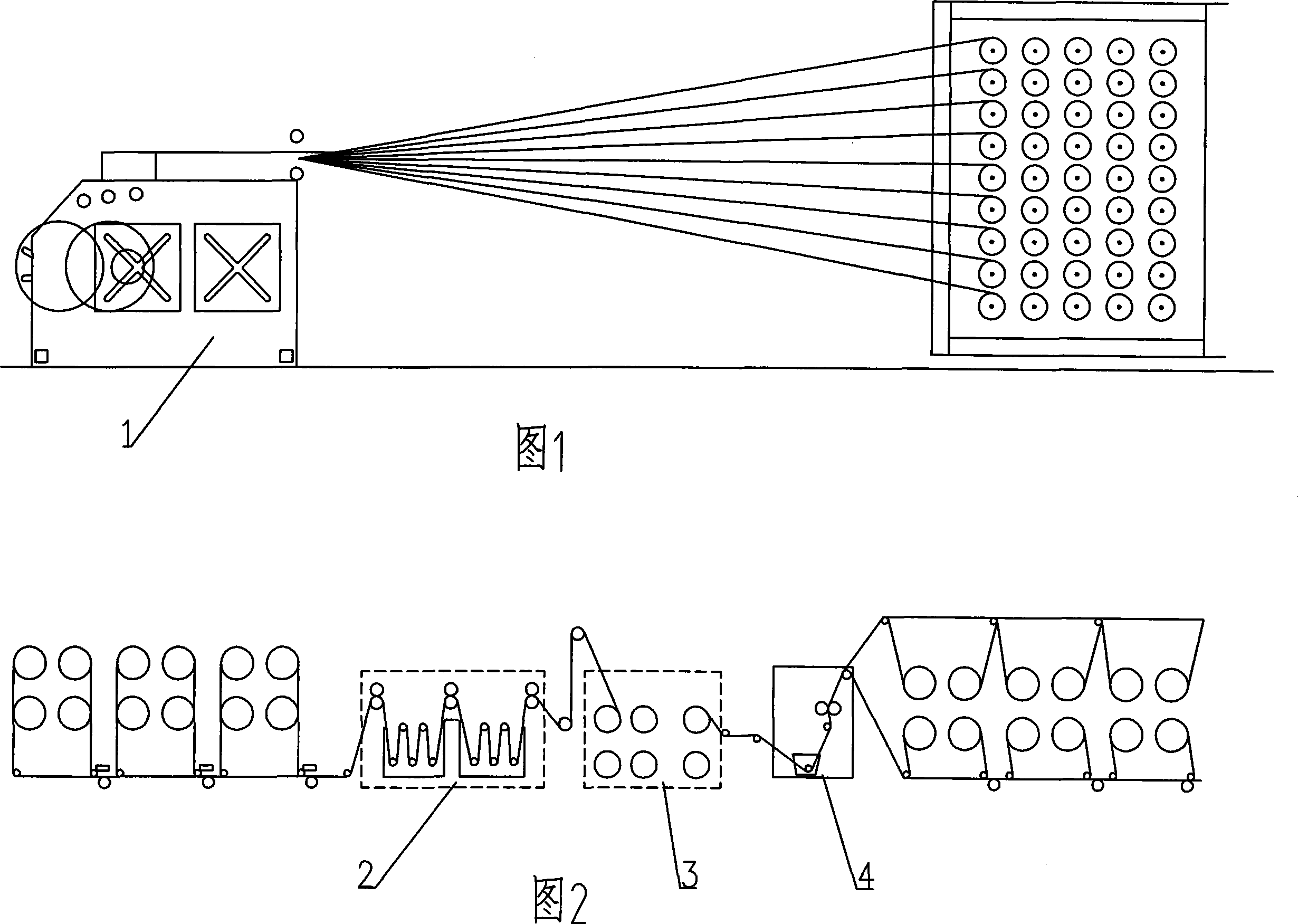

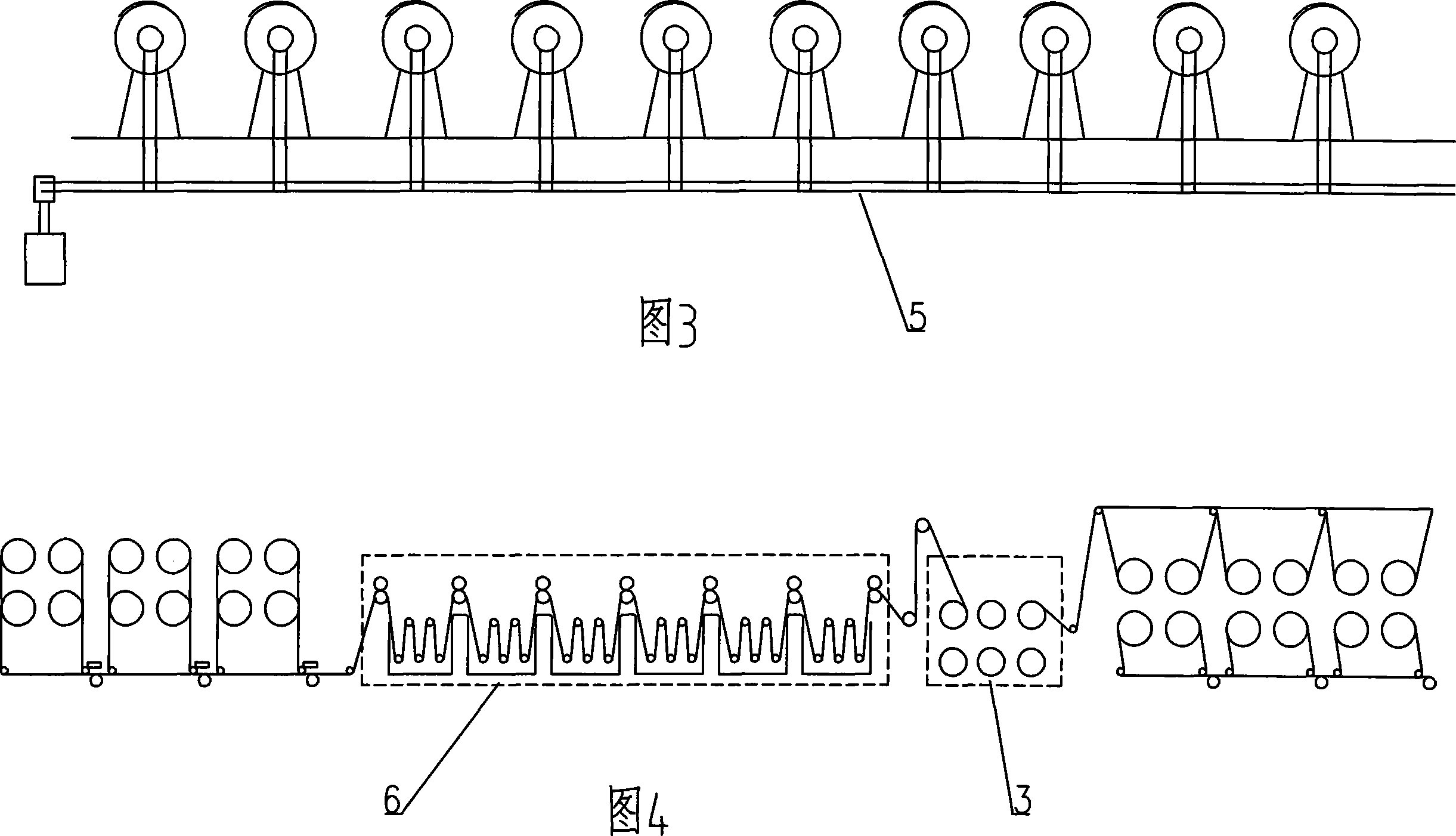

[0016] A kind of specific embodiment of the present invention, the process that has successively is: plate passing process as shown in Figure 1: the sheet yarn of composition is wound on the warp beam through high-speed warp car 1 under the same tension force; The yarn padding process shown: uniformly infiltrate the piece of yarn with the refining agent through the yarn padding machine 2, and the capillary effect is required to reach 10cm / 30min to improve the hygroscopicity of the yarn; The yarn is pre-treated, bleached and deoxidized; if it is dyed in a dark color: directly immerse the sheet yarn into the yarn padding machine for infiltration; the cold pad dyeing process shown in Figure 2 and 3: the infiltrated sheet yarn is first Dry with drying drum 3, then cool, and then cold-roll 4 pairs of sheet yarns through rolling car, and then allow sheet yarns to react and dye in cold dyeing device 5; soaping and drying as shown in Figure 4: cold dyed After the colored yarn is soape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com