Drum-type washing machine

A drum type washing machine, washing machine technology, applied to other washing machines, washing devices, textiles and paper making, etc., can solve the problems of long shock absorber, difficult to make a small drum type washing machine, valve body and piston contact collision sound, etc. Achieve the effects of reducing shock noise, reducing spring constant, and suppressing transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

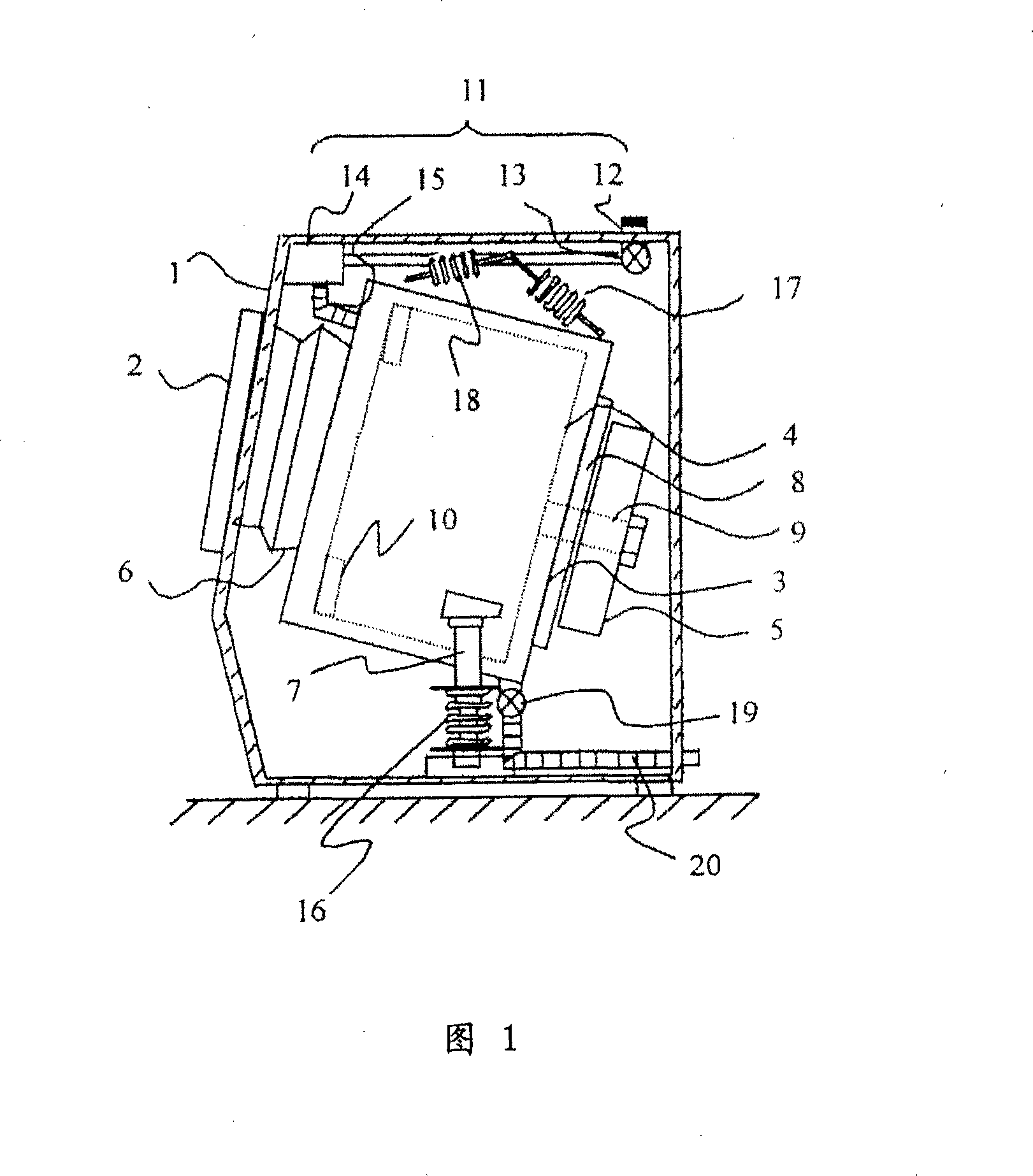

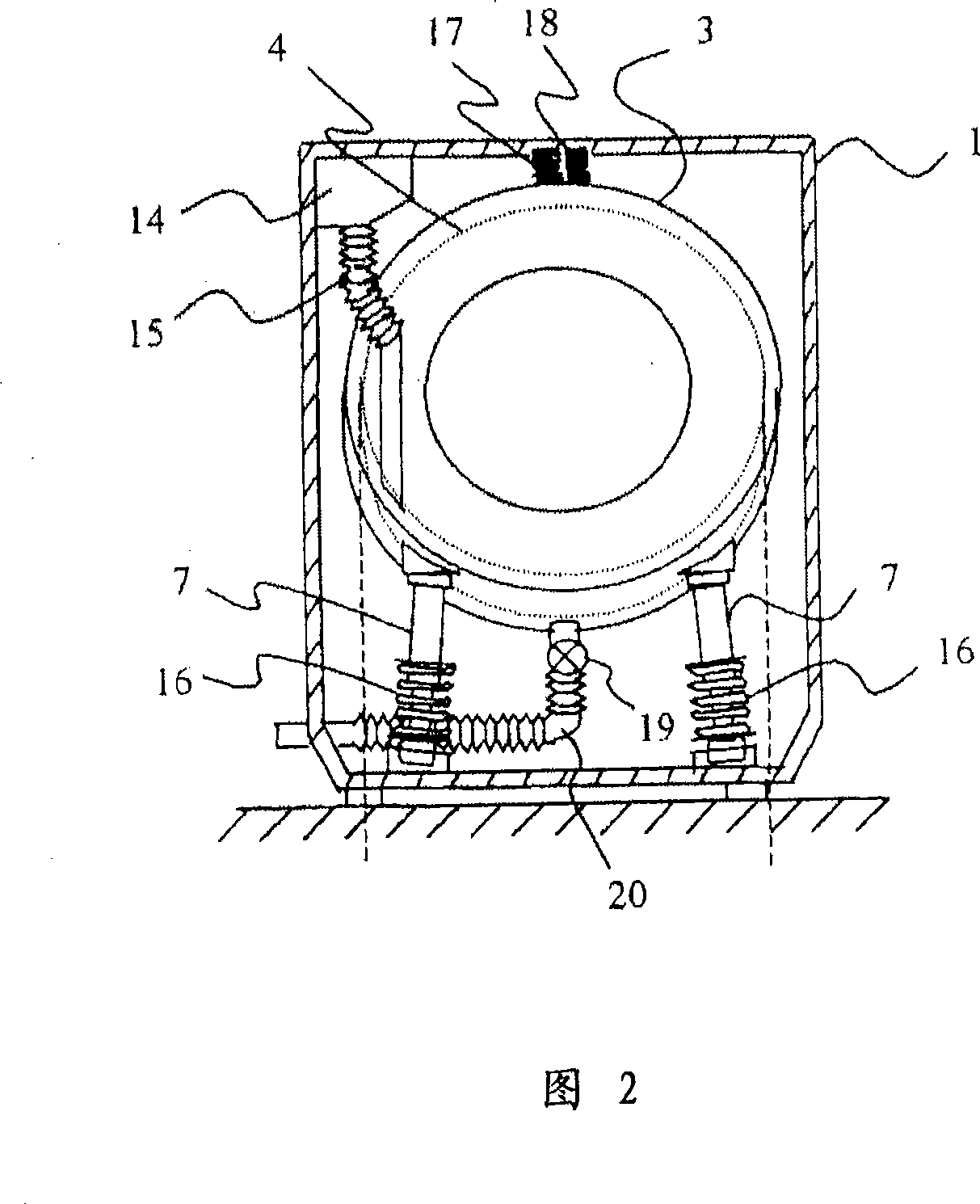

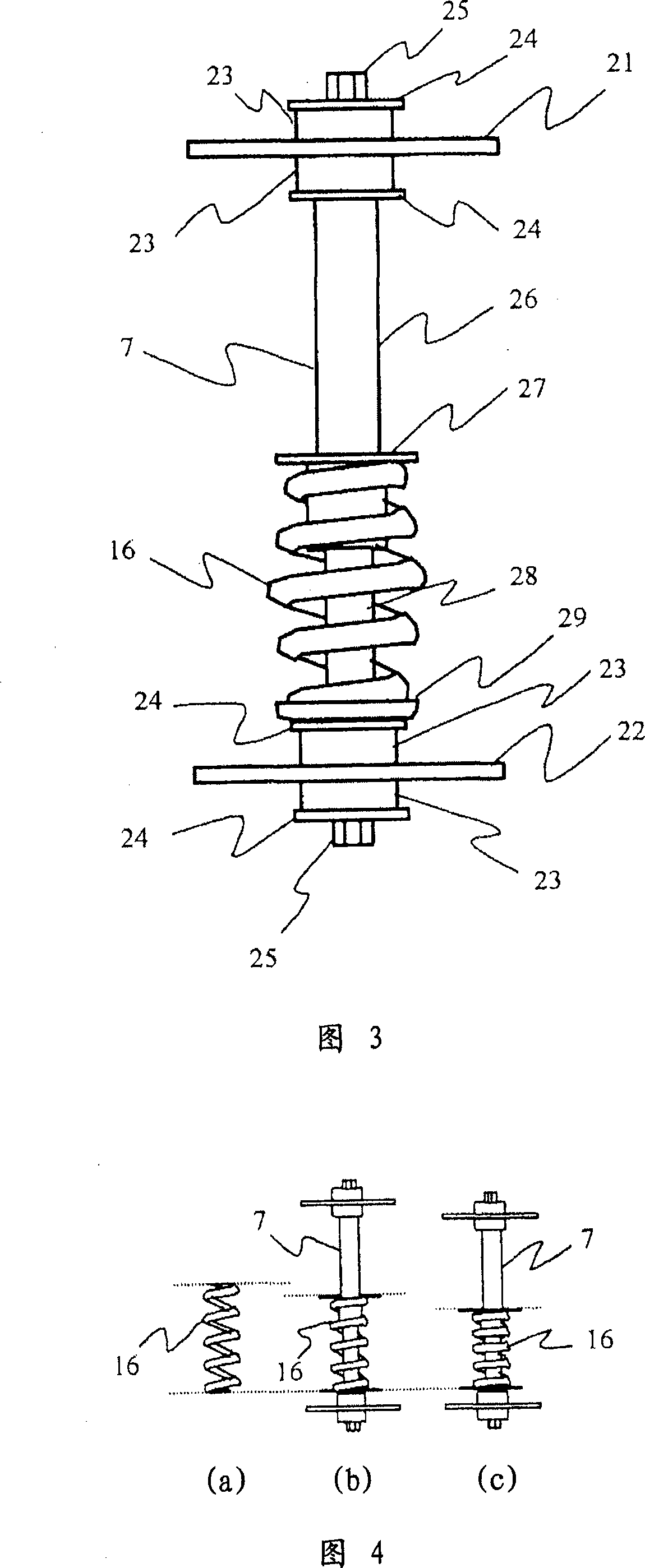

[0033] Embodiments of the present invention will be described below using FIGS. 1 to 13 . Fig. 1 is a side view of the inside of the drum type washing machine of the present invention. Fig. 2 is a front view of the interior of the drum-type washing machine of the present invention. In addition, FIG. 3 is an external view of a hanger in which a spring supporting a water cylinder and a damper are combined. The present invention is not limited to a drum type washing machine, and may be applied to a drum type washing and drying machine equipped with a drying device such as a heater or a fan.

[0034] There is an inlet for laundry in front of the cabinet 1 of the washing machine, and a door 2 is provided. By opening and closing the door 2, laundry can be taken out or put in. In addition, inside the housing 1 , the inlet side is inclined upward by 0° to 30° from the horizontal line, and a cylindrical water tank 3 with an opening on the inlet side is disposed. The opening of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com