ARM-based flat wheel detection and control system

A technology of detection and control system and flat wheel, applied in signal transmission system, electrical signal transmission system, instrument, etc., can solve the problems of reduced efficiency and real-time performance, construction cost, maintenance cost, high expansion cost, and increased design difficulty. Achieve the effects of improving system stability and reliability, tailorable real-time performance and reliability, excellent real-time performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0025] 1. Hardware part:

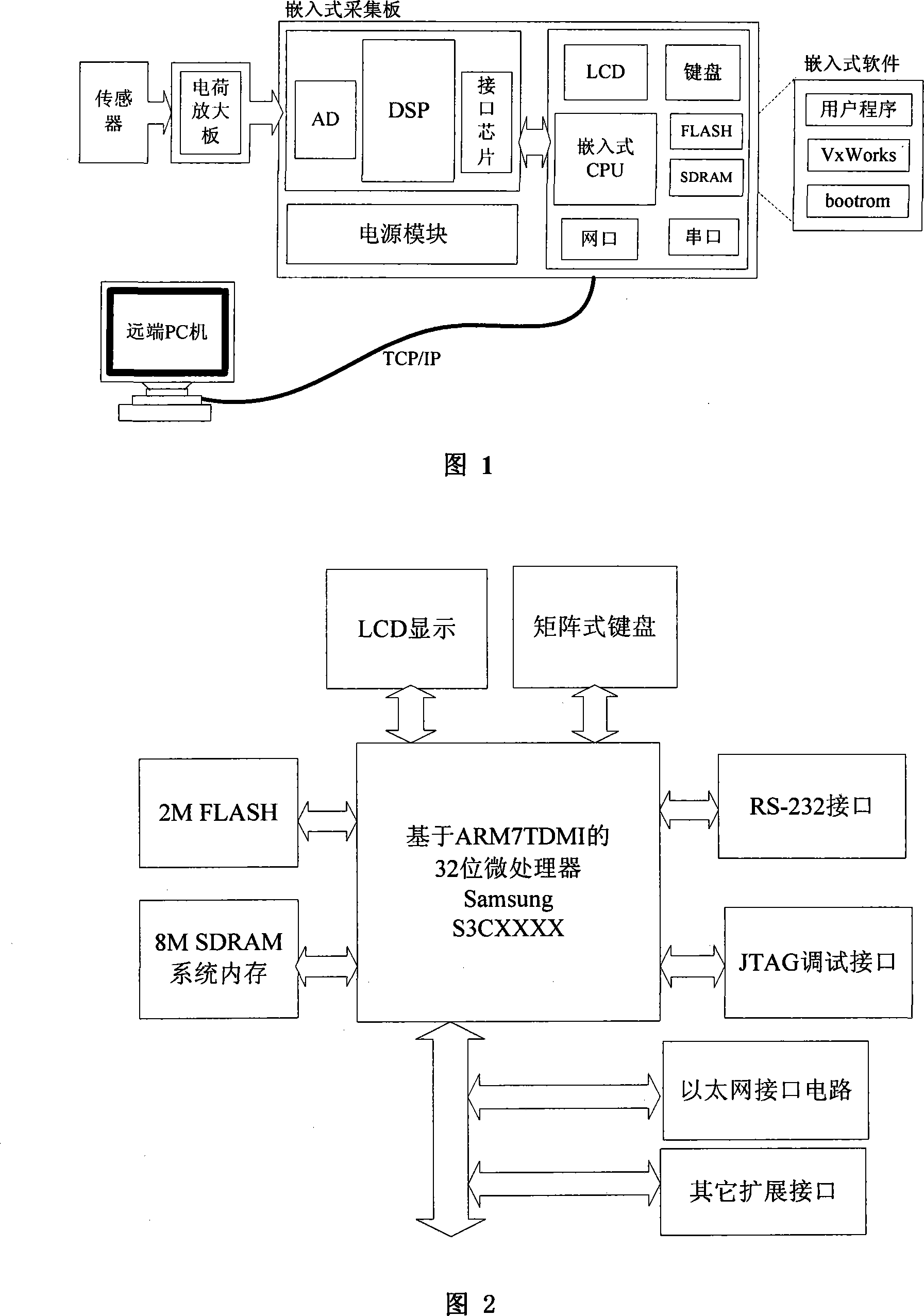

[0026] Combined with Figure 2, the specific details are as follows:

[0027] 1) The embedded main CPU adopts the representative microcontroller S3CxxB0 with ARM7TDMI core of Samsung Company, and the maximum main frequency can reach 66MHz.

[0028] 2) The 8M memory SDRAM adopts HY57V64xxxx, which is used as the space for the system code to run, namely: [0x0C000000~0X0C800000]. The data lines D15~D0 are connected to the main chip data lines DATA15~DATA0, the address lines A11~A0 are connected to the main chip address lines ADDR12~ADDR1, and the control lines are respectively connected to the main chip nWBE0, nWBE1, nSCKE, nSCLK, nSCS0, nSRAS, nSCAS connected.

[0029] 3) 2M FLASH[0x00000000~0X00200000] is used for curing program, using AM29LVxxxDB, its data lines D15~D0 are connected with main chip data lines DATA15~DATA0, address lines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com