A single-point soldering pot mouth with overflow tin hole

A tin overflow, single-point technology, applied in the direction of assembling printed circuits with electrical components, can solve the problems of high equipment requirements, pressure fluctuations affecting welding area and welding quality, and affecting welding quality, etc., to achieve strong adaptability and stable tin pressure. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

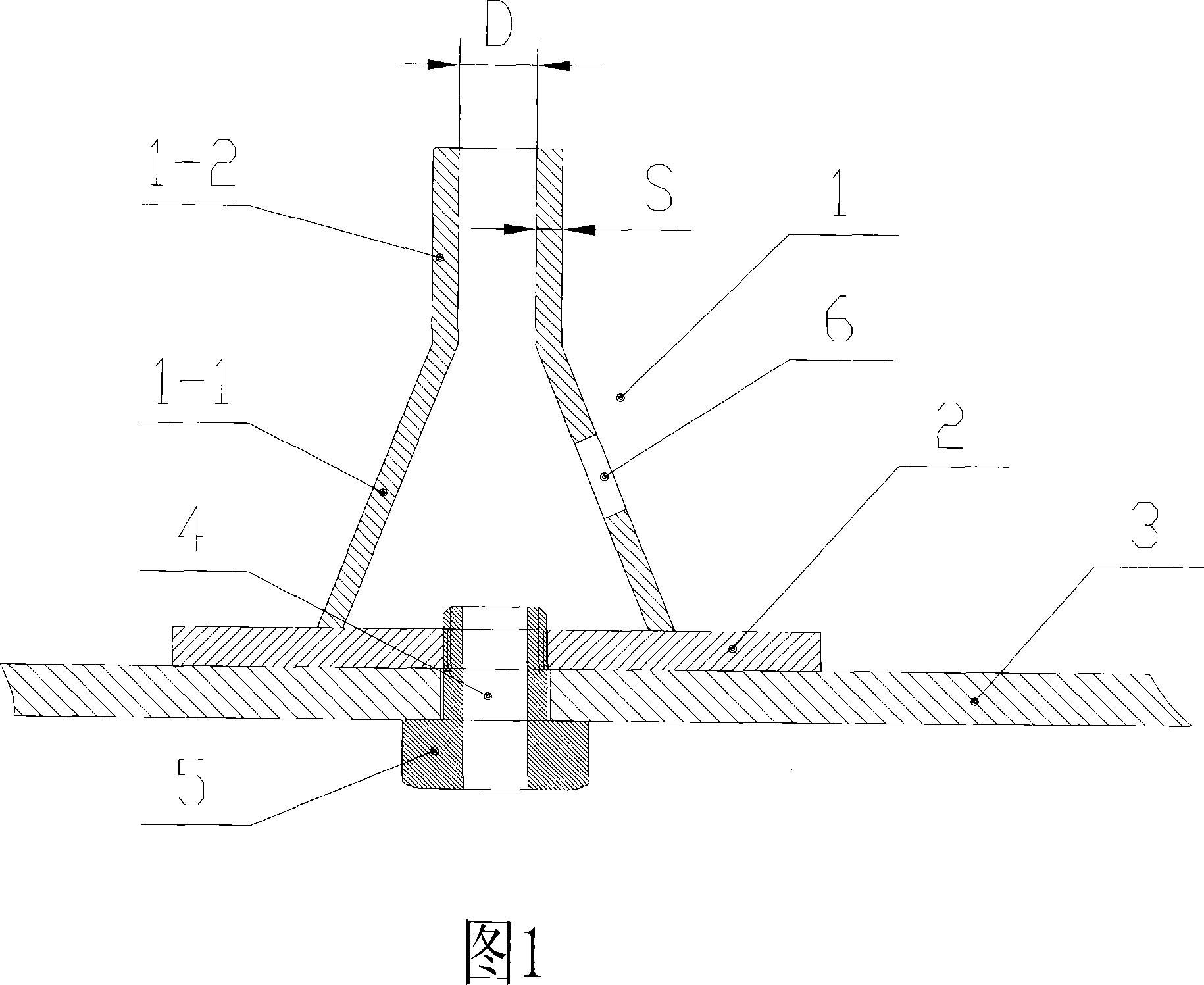

[0012] As shown in Figure 1, a single-point welding spout with a tin overflow hole is composed of a shrinkage-shaped tin spray tube 1 and a lower bottom plate 2. The tin spray tube 1 is fixed on the lower bottom plate 2, and on the tin spray tube 1 A tin overflow hole 6 is provided, and the lower bottom plate 2 is installed on the tin furnace panel 3, and the two can be fixedly connected together by welding. On the lower bottom plate 2 and the tin stove panel 3, there is a through tin inlet hole 4, and a hollow nut 5 is screwed in the tin inlet hole 4 to fix the lower bottom plate 2 and the tin stove panel 3 together. The tin-spraying tube 1 is composed of a tapered tube body 1-1 and a cylindrical tin-spraying port 1-2, wherein the inner diameter of the tin-spraying port 1-2 is D=2-10mm, and the wall thickness S=0.5-3mm.

[0013] When in use, molten tin enters from the tin furnace through the hollow nut 5 into the spout formed by the tin-spraying tube 1 and the lower bottom pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com