Electric actuator

A technology of electric actuators and electric motors, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems that electric actuators cannot be realized, and achieve the effect of high controllability and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

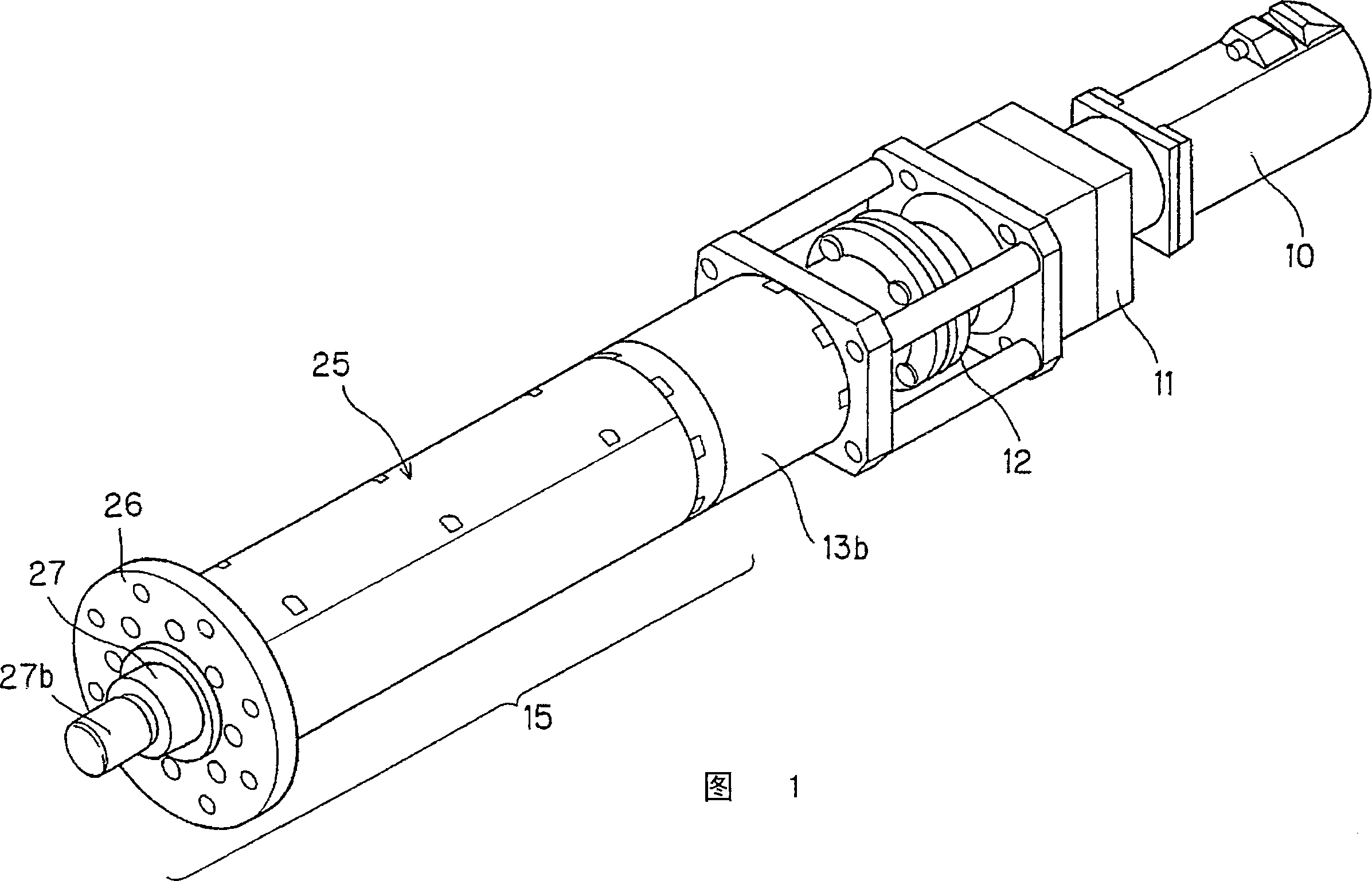

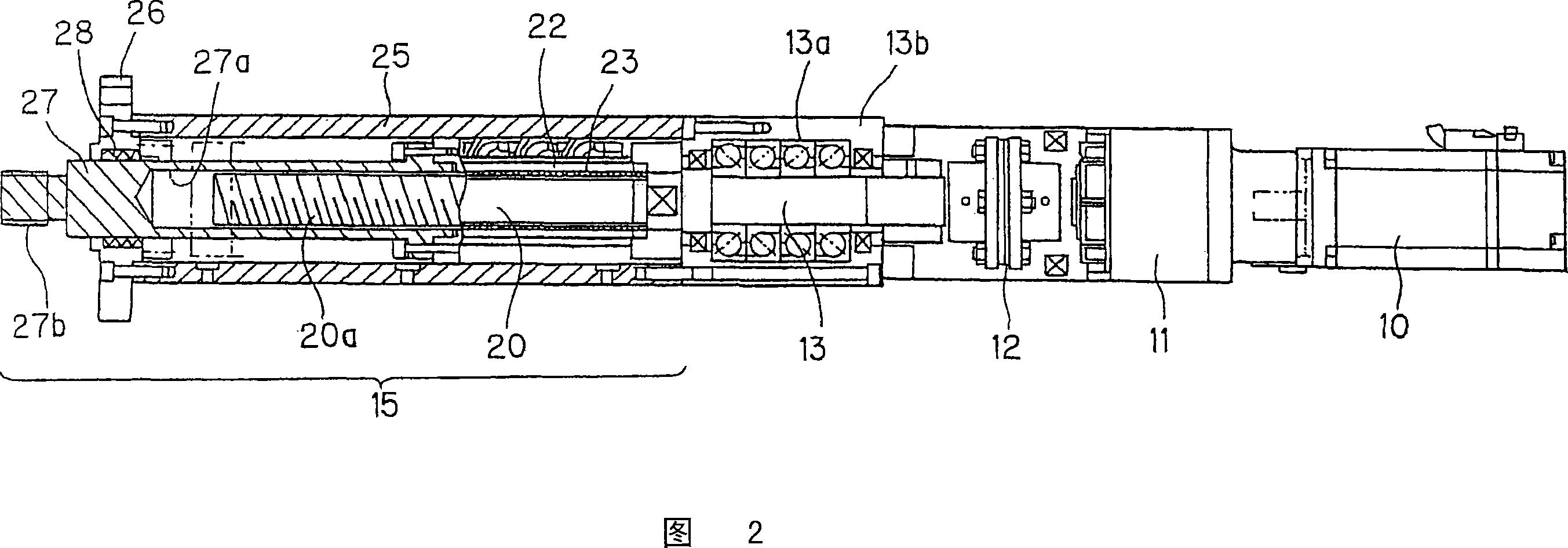

[0034] FIG. 1 is an external perspective view showing the overall configuration of an electric actuator according to a first embodiment. In addition, FIG. 2 is a longitudinal sectional side view of the electric actuator according to the first embodiment.

[0035] The electric actuator of the first embodiment includes an electric motor 10 as a drive source. The electric motor 10 is provided at an end portion opposite to the installation position of the cylinder rod 27 as an action portion, and a rotational driving force is provided by an output shaft of the electric motor 10 .

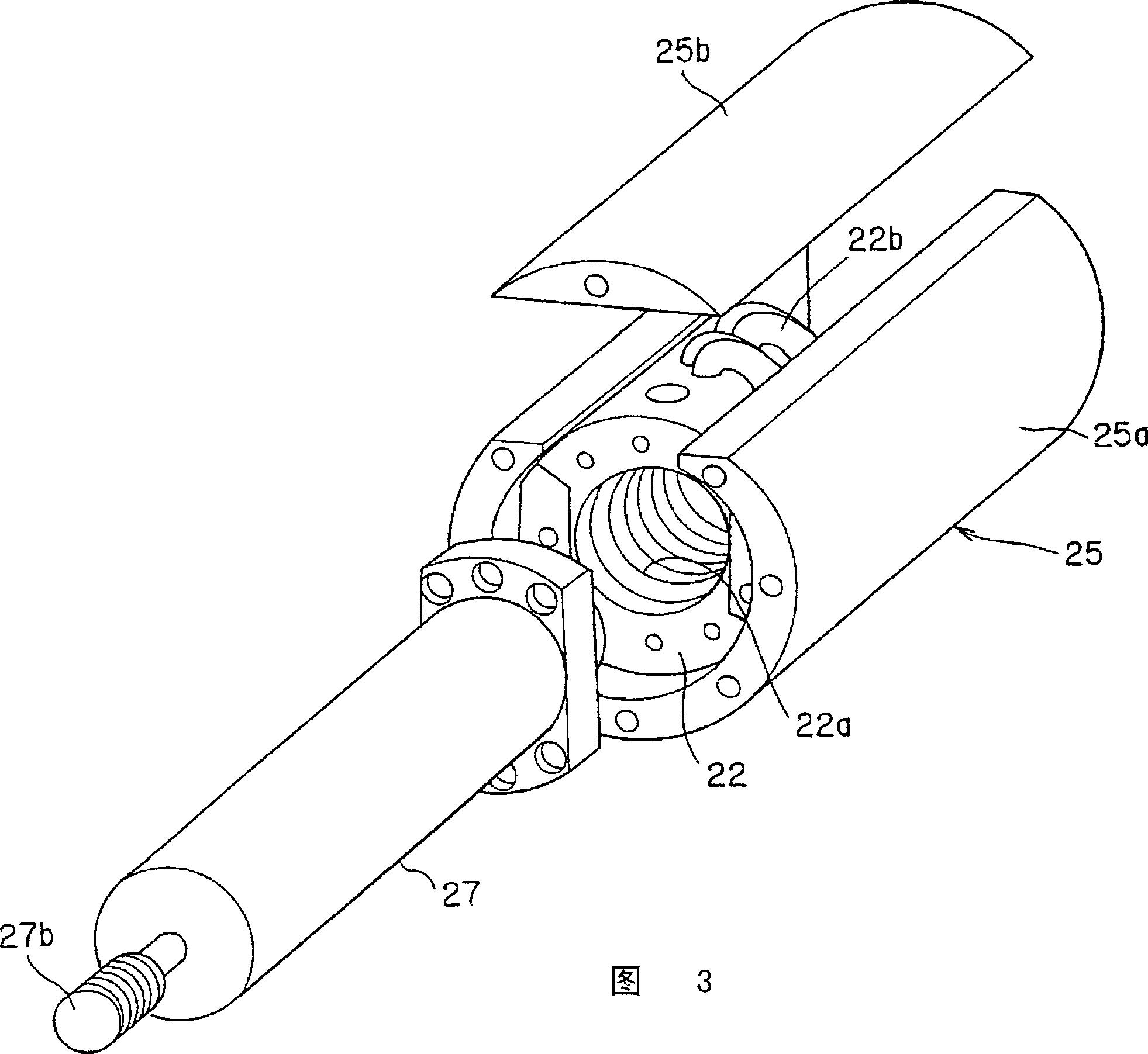

[0036] On the output shaft of the electric motor 10, a speed reducer 11 for increasing torque amplification, increasing inertial force, reducing vibration, etc. is provided continuously. In addition, a connecting shaft 13 supported by a coupling 12 and a rolling bearing 13 a is provided at an end of the speed reducer 11 , and a power transmission mechanism 15 is further provided at an end thereof. In ...

no. 2 Embodiment approach

[0069] In the above-mentioned first embodiment, the case where the components of the electric actuator such as the electric motor 10 , the speed reducer 11 , the coupling 12 , the connecting shaft 13 , and the power transmission mechanism 15 are connected in series has been described as an example. In the second embodiment described below, an electric actuator suitable for use when the installation space in the axial direction is limited will be described. In addition, the same code|symbol is attached|subjected to the component demonstrated in 1st Embodiment, or a similar component, and description is abbreviate|omitted.

[0070] 9 is an external perspective view showing the overall configuration of an electric actuator according to a second embodiment. In addition, FIG. 10 is a longitudinal sectional plan view of the electric actuator of the second embodiment.

[0071] In the electric actuator of the second embodiment, the coupling provided in the first embodiment is omitted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com