Metal slicing machine

A slicing machine and metal technology, used in metal processing machinery parts, metal processing, metal processing equipment and other directions, can solve the problems of poor product consistency, complex processing technology and high cost, and achieve the effect of low cost, high efficiency and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

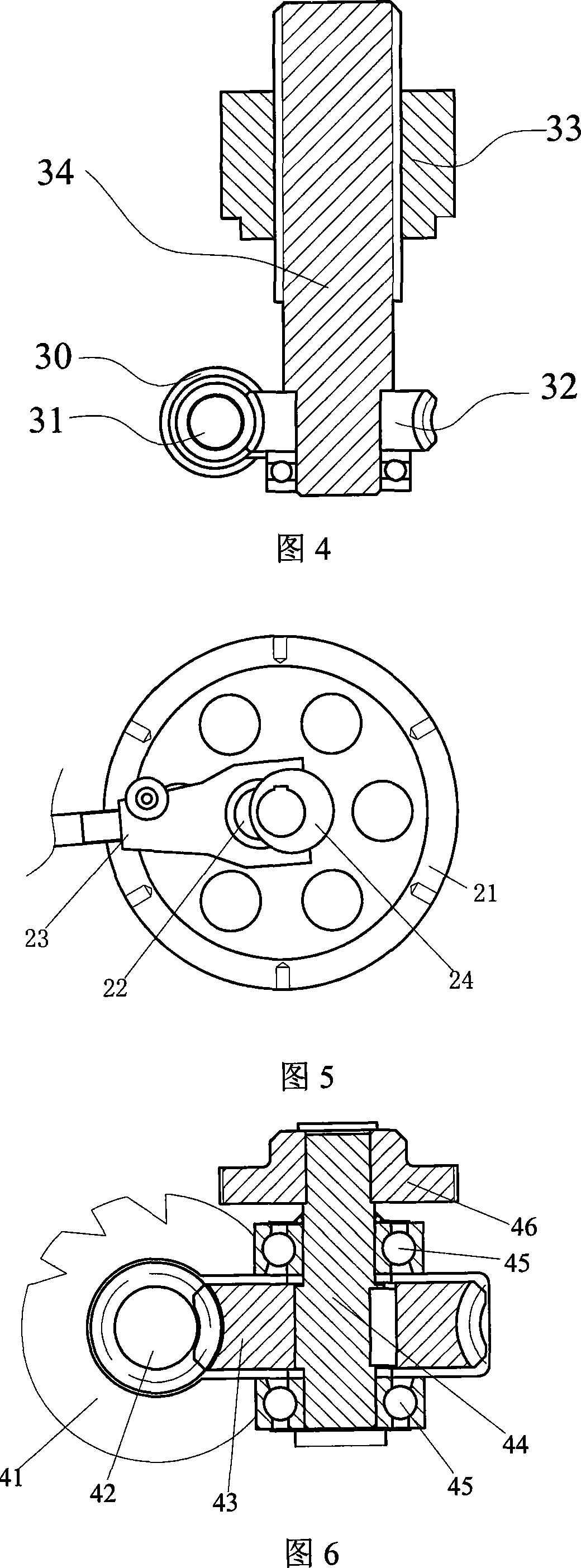

[0047] The metal slicer according to the specific embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

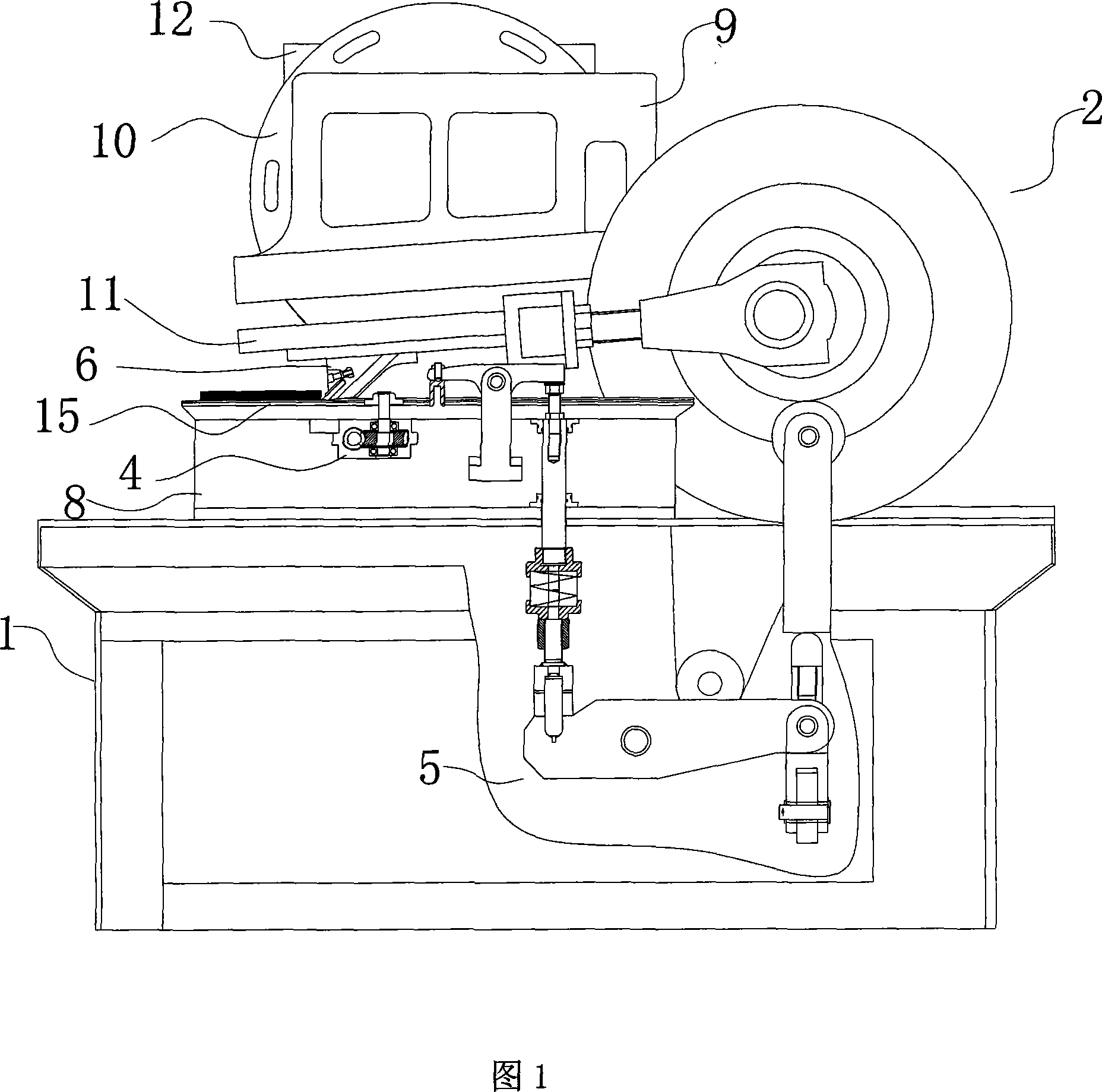

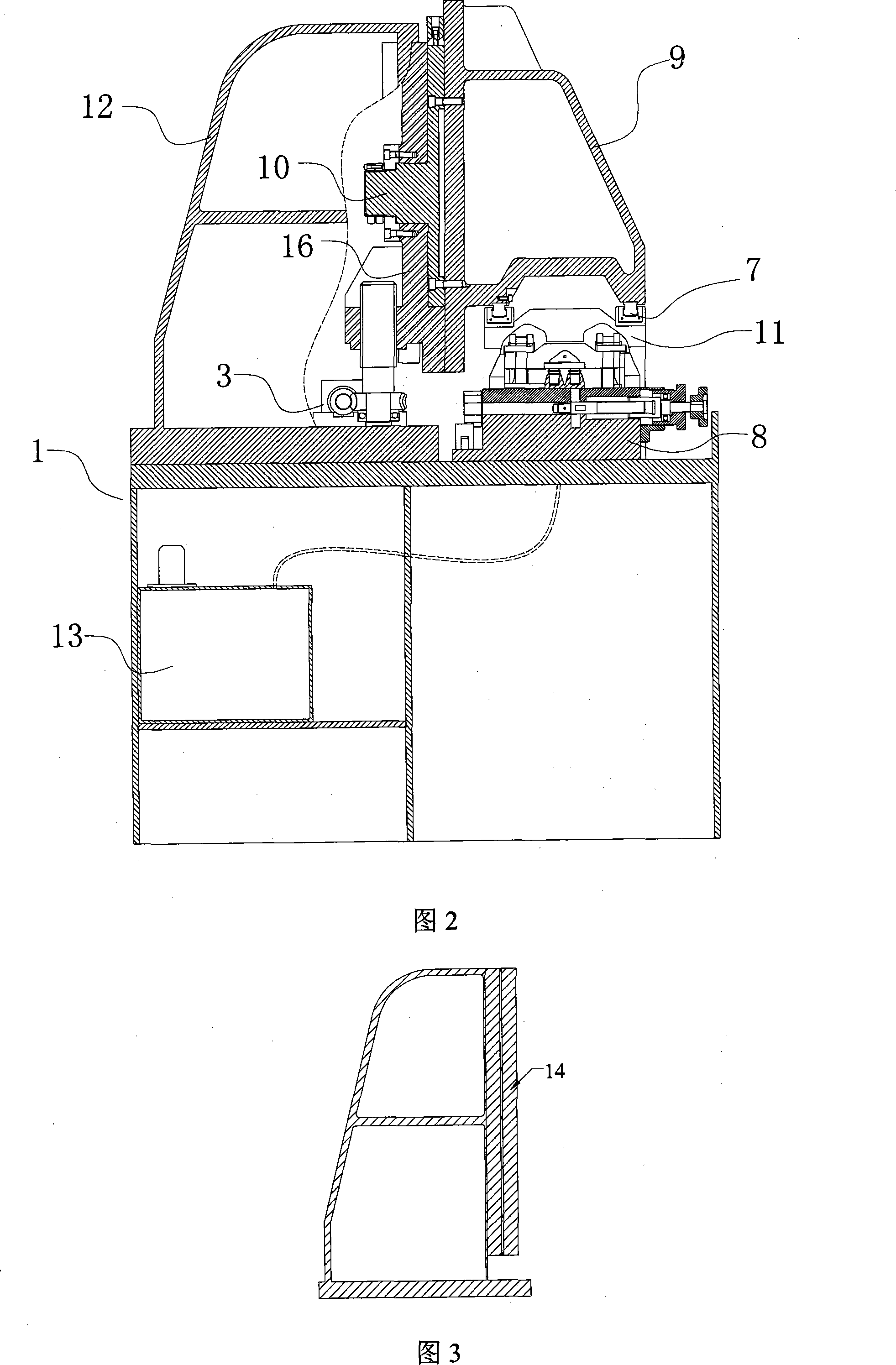

[0048] As shown in Figures 1 and 2, the metal slicer mainly includes a frame, a track position adjustment system, a sliding mechanism, a drive system 2, a feeding mechanism 4, a pressing mechanism 5 and a knife body assembly 6.

[0049] Wherein the frame includes a lathe bed 1, a workbench 8 and a vertical slide seat 12. The bed 1 is the main body of the frame, which is a frame structure welded by section steel, beautiful in shape, easy to manufacture, low in cost, and convenient for loading, unloading and maintenance. The section steel has been quenched and tempered before welding to ensure that the bed is not easily deformed during future use. The workbench 8 is located on one side of the bed 1 and mainly provides a bearing platform for the base material 15 to be processed. The vertical slide base 12 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com