Air conditioner heat-exchanger brass pipe defect servicing technique method and special-purpose apparatus for implementing the method

A technology of heat exchanger and repair technology, which is applied in the field of defect repair of copper tubes, can solve problems such as scrapped heat exchangers, losses of copper tube manufacturers, economic losses of air-conditioning manufacturers, etc., and achieve the effect of improving efficiency and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0033] The technical method for repairing copper tube defects of air-conditioning heat exchangers, firstly put the defective air-conditioning heat exchangers to be repaired into water, and detect the defective copper tubes by inflating and bubbling.

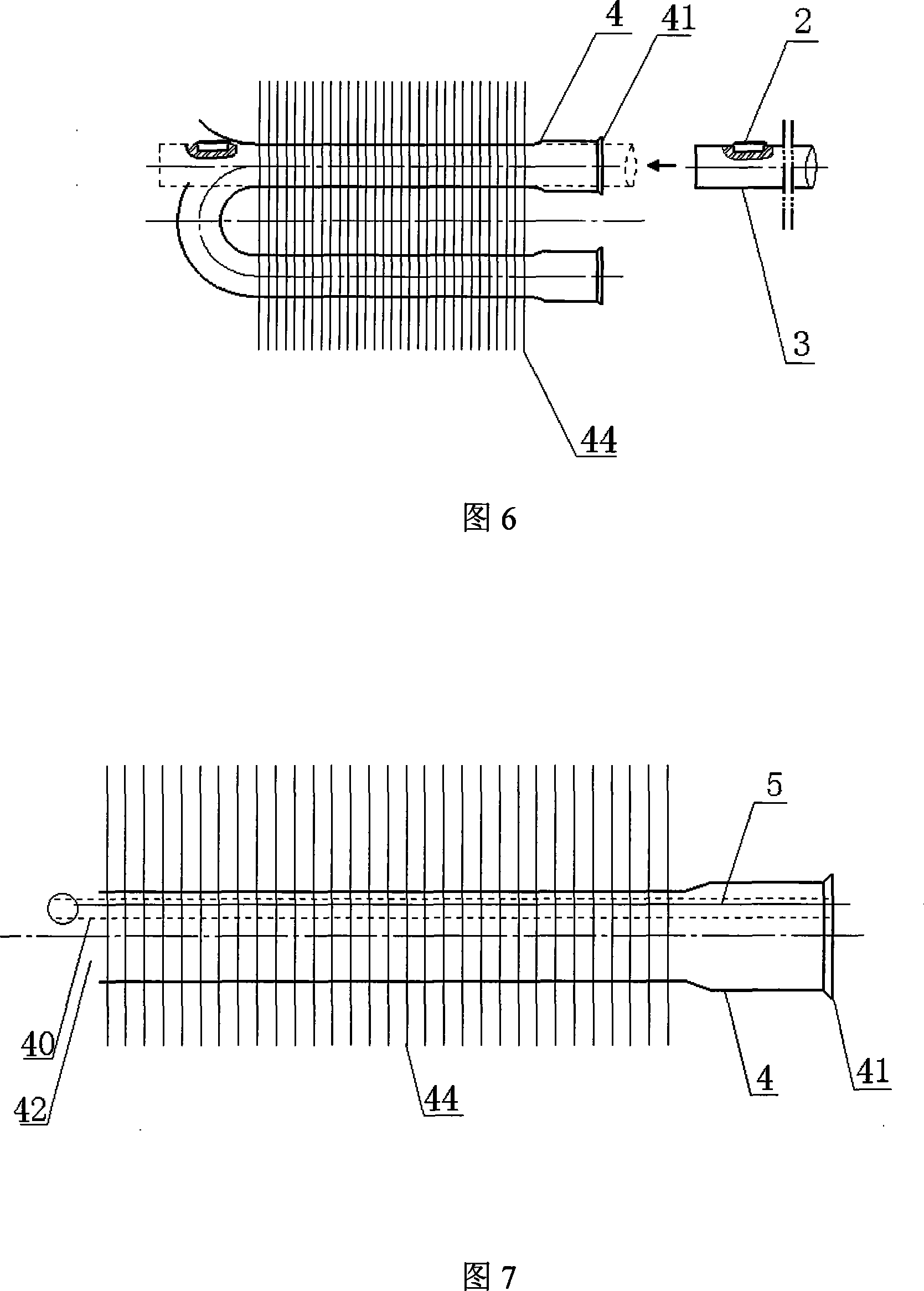

[0034] Use scissors or diagonal pliers to cut off the "U" part of the copper tube; in this way, the "U" copper tube (hairpin tube) is divided into two sections. It is also possible to cut out the copper skin first, and then cut off the "U"-shaped part of the copper pipe.

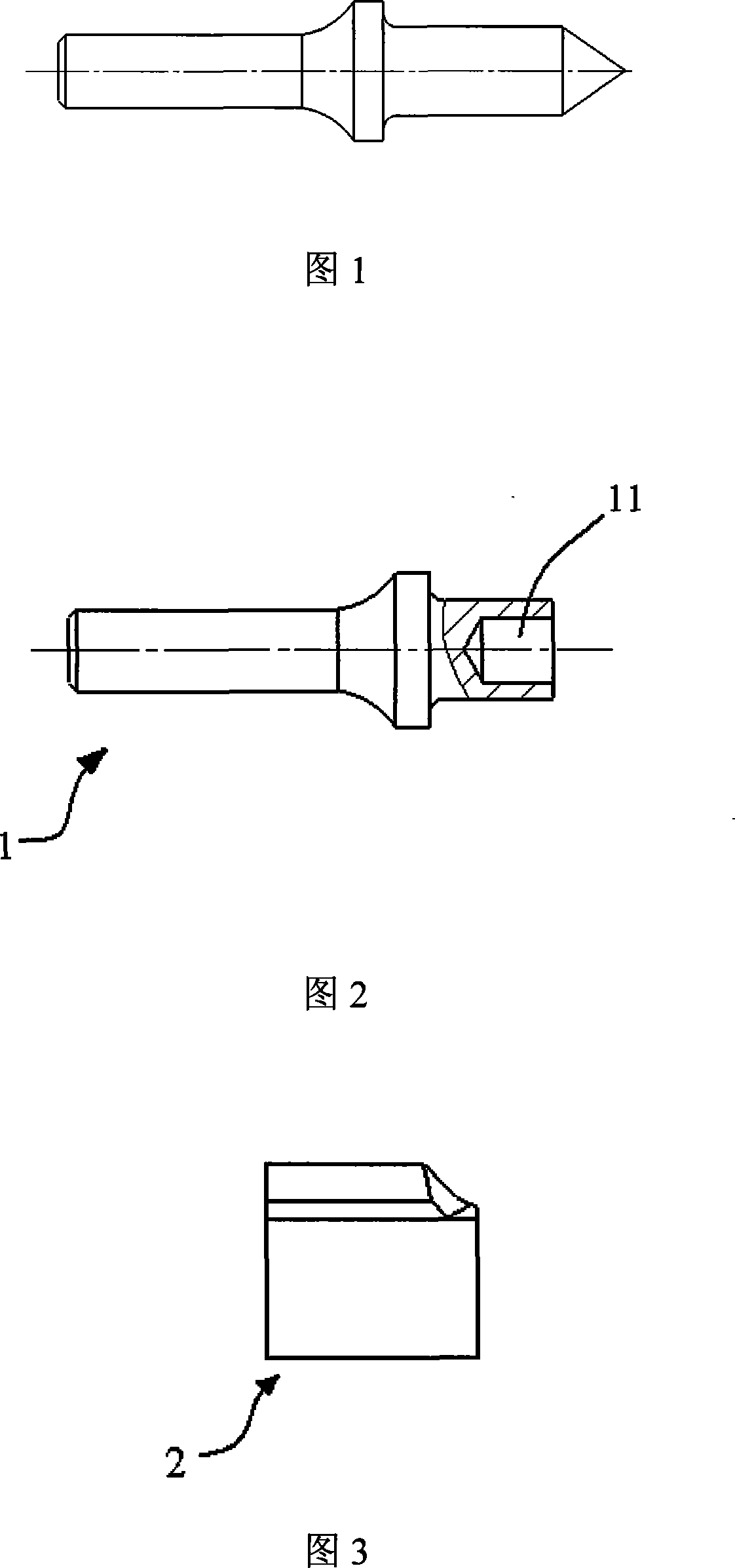

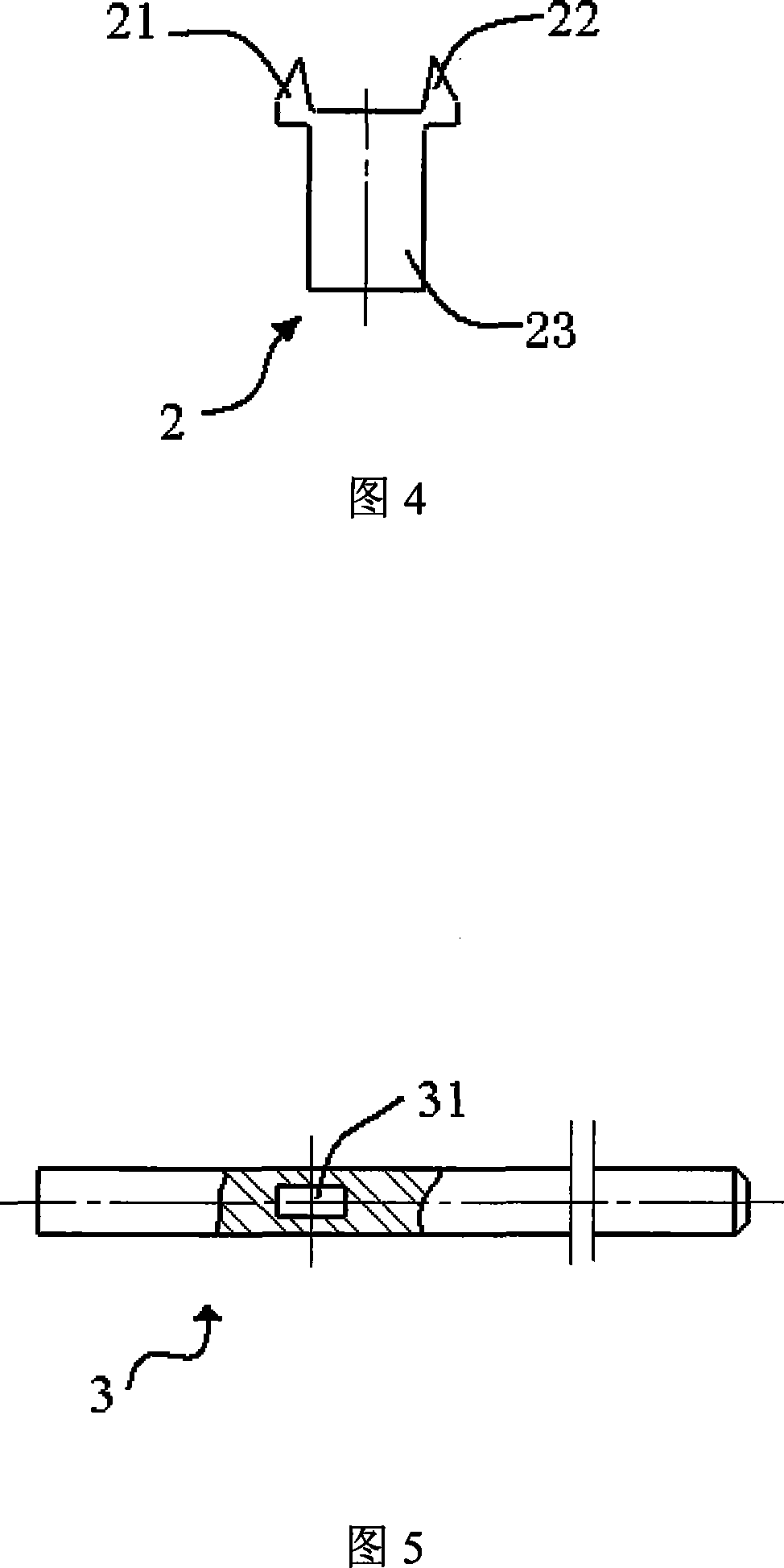

[0035] Then, one section of the copper pipe 4 is placed on the plastic pad of the working platform. Connect the air source to the air hammer, connect the air hammer to the connector 1; assemble the cutter bar 3 and the blade 2; as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com