Thick steel plate having excellent toughness and reduced softening in weld heat-affected zone

A technology for welding heat-affected, thick steel plates, which is applied in the field of thick steel plates, can solve the problems of HAZ toughness reduction, no consideration, etc., and achieve excellent toughness, excellent mechanical properties, and the effect of inhibiting HAZ softening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

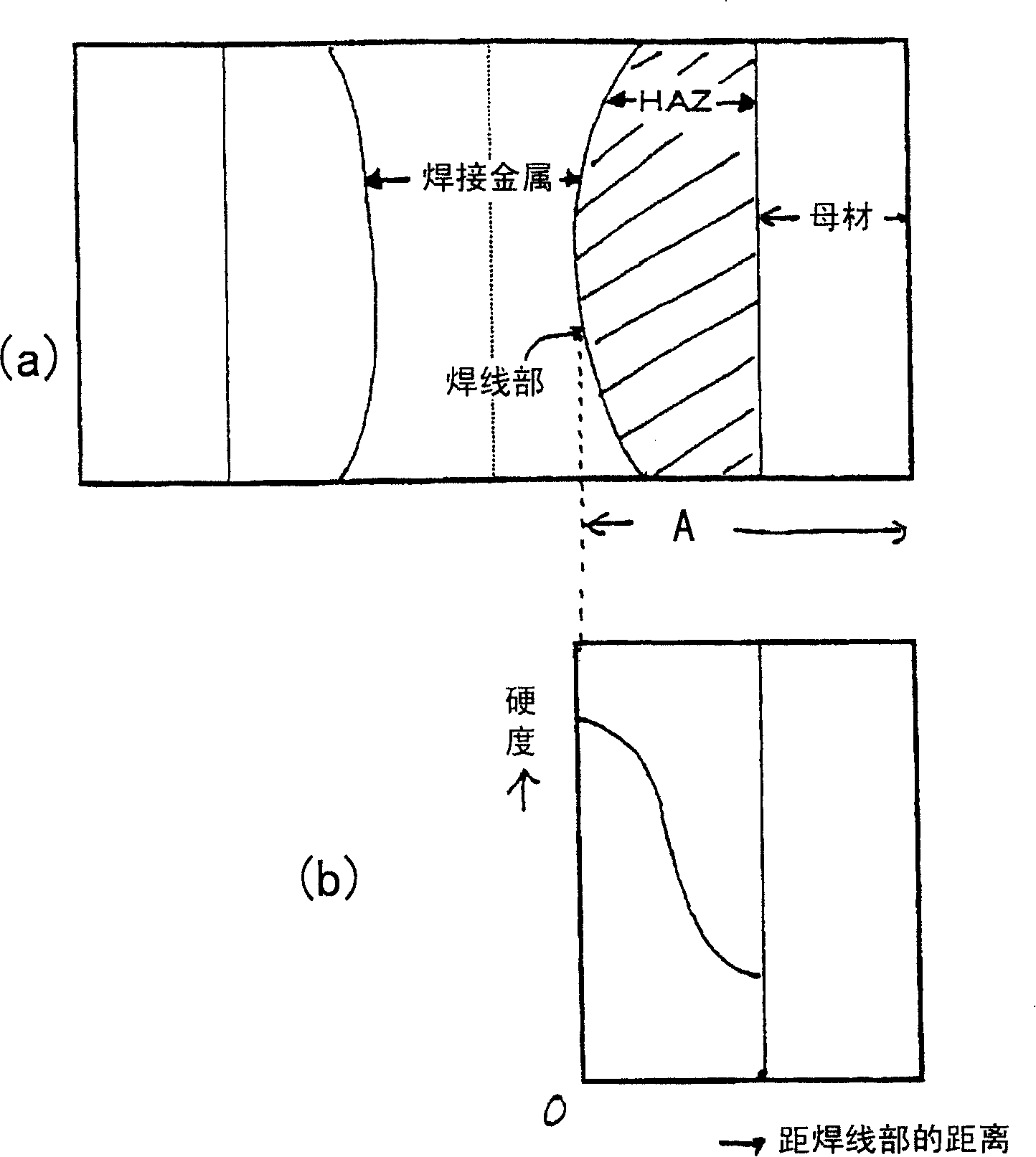

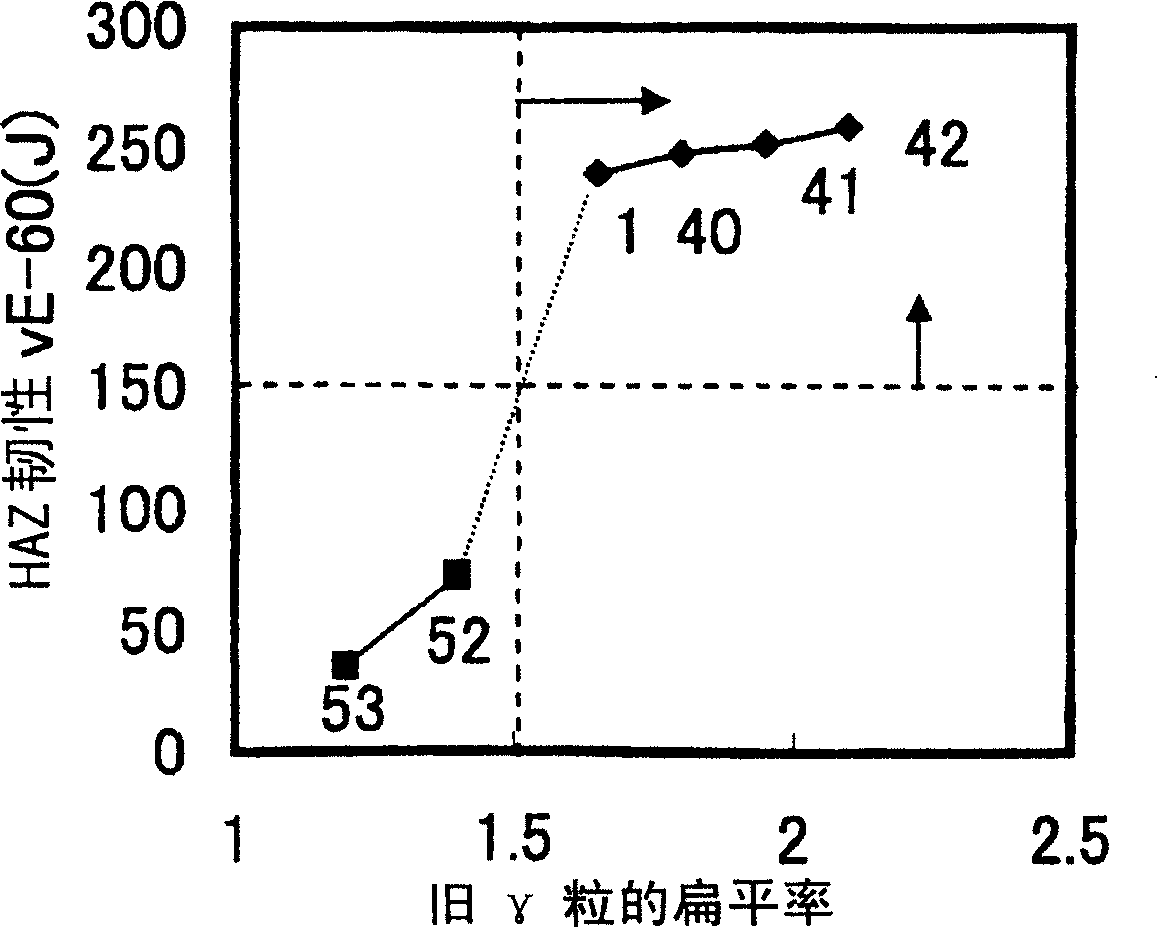

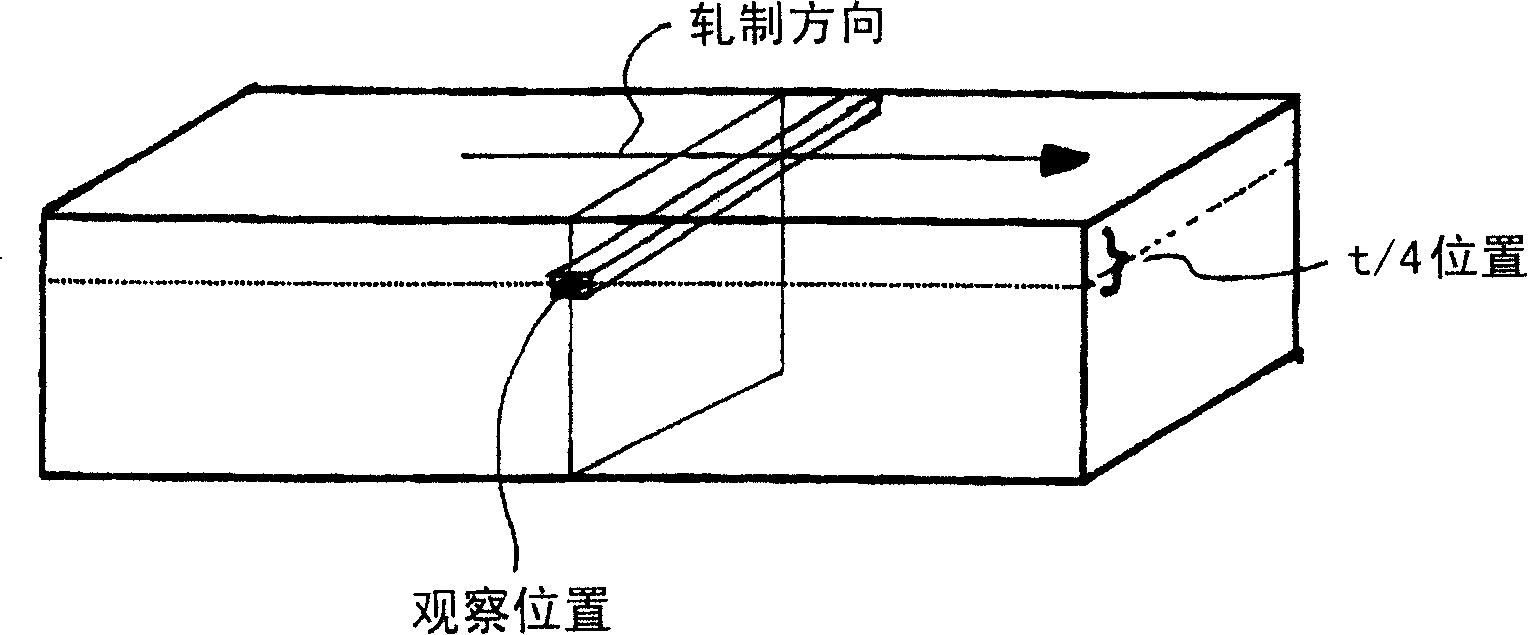

[0029] The inventors of the present invention have conducted intensive research to provide a thick steel plate with excellent HAZ toughness and suppressed HAZ softening even when a thick steel plate with a thickness of about 60 mm or more is welded with an ultra-high heat input of more than about 60 kJ / mm. . As a result, it was found that in order to make these properties coexist, Ti, N, and B are used among the components in the steel, and it is sufficient to control the shape of the old γ grains into a flat shape as the pre-structure of the base material. In detail, it was found that: (a) Mainly, the maximum Maximize the HAZ toughness effect of fine TiN; and (b) for N, ensure hardenability by excessively adding Ti and B (in addition, Nb as needed), and by suppressing ferrite transformation, it is possible to maximize Minimizes the softening of the HAZ. Then, as a result of repeated studies in order to find the constituent requirements for effectively exerting such an effec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com