Suction pump jet driving device without delivery lift

A driving device and jet technology, applied in pump devices, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of heavy environmental pollution, abnormal power supply, and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

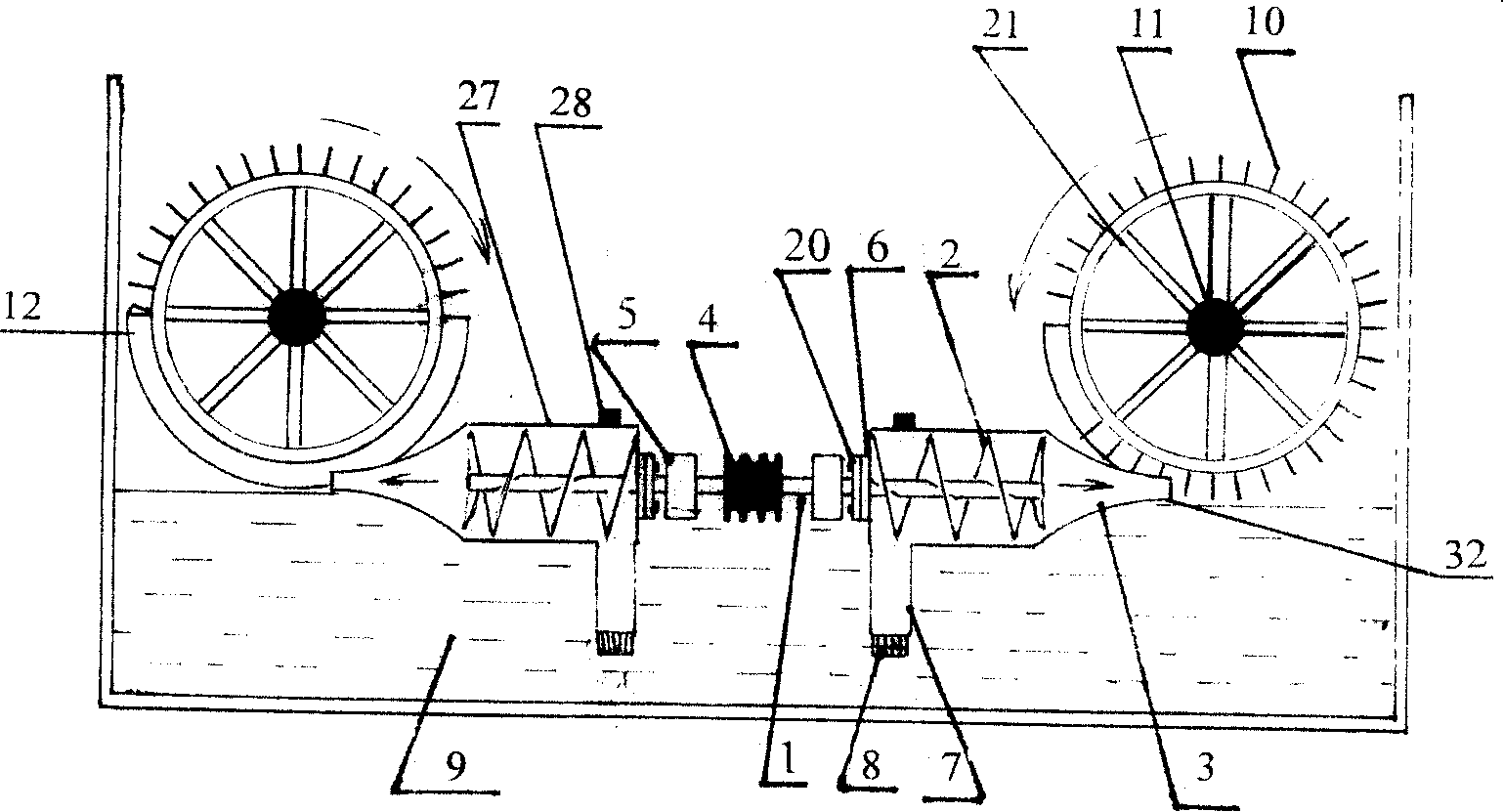

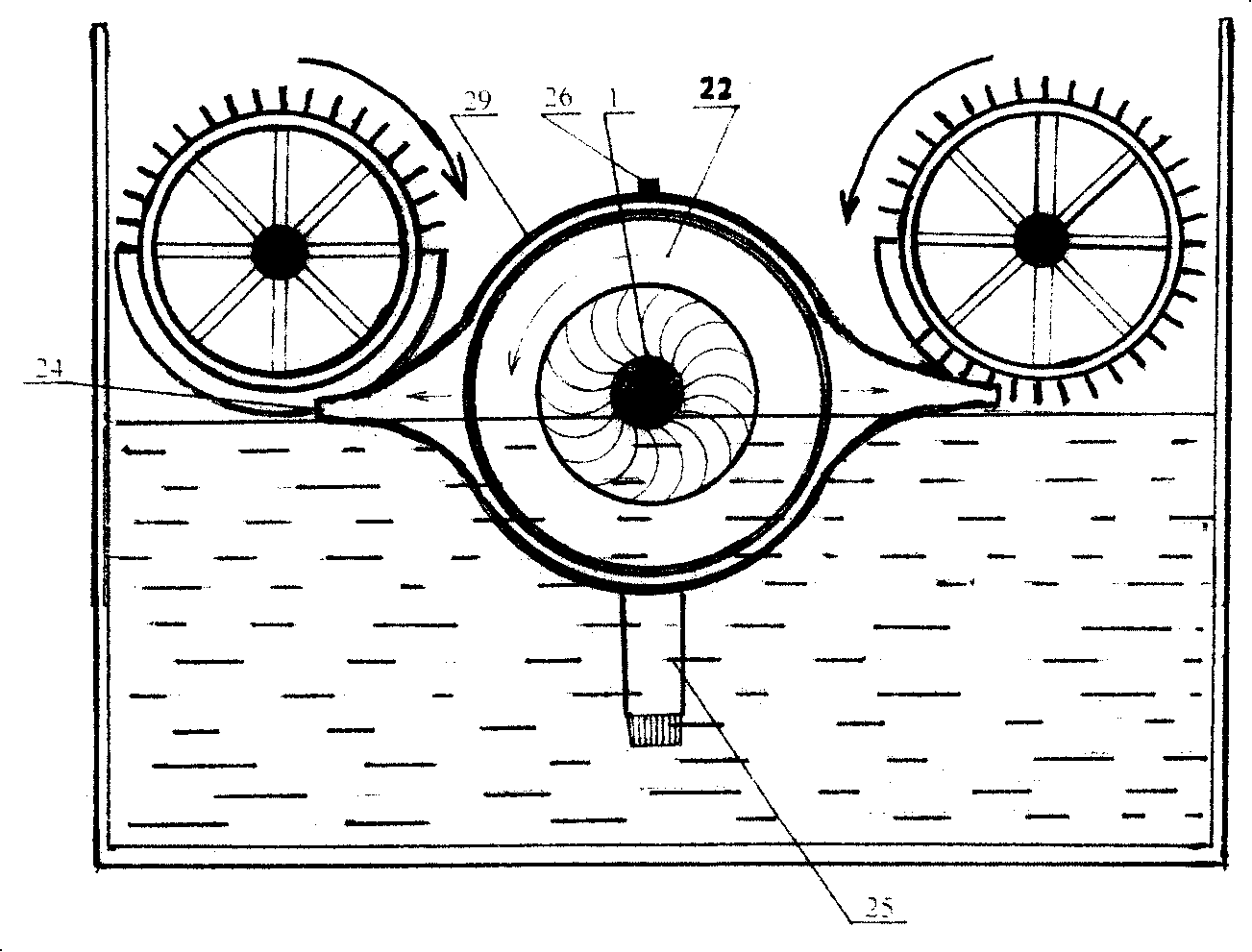

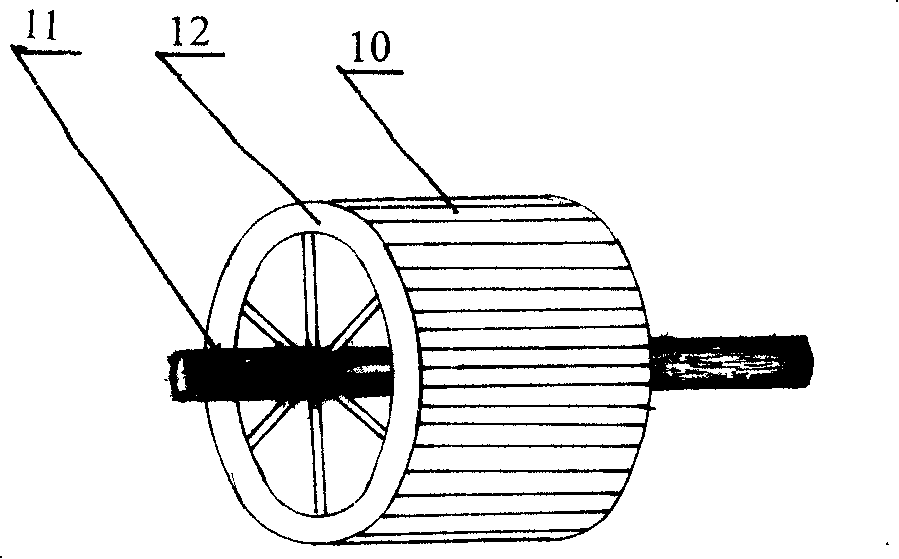

[0044] Embodiment 1, water turbine φ 2.2 meters, width 0.7 meters, 14 units are installed on the same combined shaft, including 6 units on the left and right sides, 12 units on both sides, and one at the front and rear ends. The length of the combined shaft = the width of the left and right water turbine rollers 0.7 × the number of 6 + the length of the runners of the axial flow suction and discharge pump at both ends 1.2 meters × the number of runners 2 + the position occupied by the installation of the drive wheel, bearings, bearing seats and coupling joints A total of 1.6 meters=8.2 (meters) with the gap, and each water turbine is fitted with a generator, which can drive 14 generators in total.

Embodiment 2

[0045] Embodiment 2, water turbine φ0.7m, roll body width 0.3m, 18 units are installed on the same combined shaft, including 8 units on each side of the left and right sides, 16 units on both sides, and 1 unit at the front and rear ends. The length of the long axis of the formula = the width of the turbine 0.3 × the number of units 8 + the length of the runners of the axial flow suction and discharge pump at both ends 0.8 × the number of runners 2 + the positions and gaps occupied by the drive wheel, bearings, bearing seats and coupling joints are 1 m=5 (m). Eight water turbines on each side of the left and right sides are installed on the same long root to jointly drive the same generator, and the 18 water turbines drive a total of 4 generators of different sizes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com