High-vacuum packing machine with primary heater unit

A preheating device and packaging machine technology, applied in electric heating devices, packaging, transportation packaging, etc., can solve problems such as uneven heat conduction, and achieve the effect of improving the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

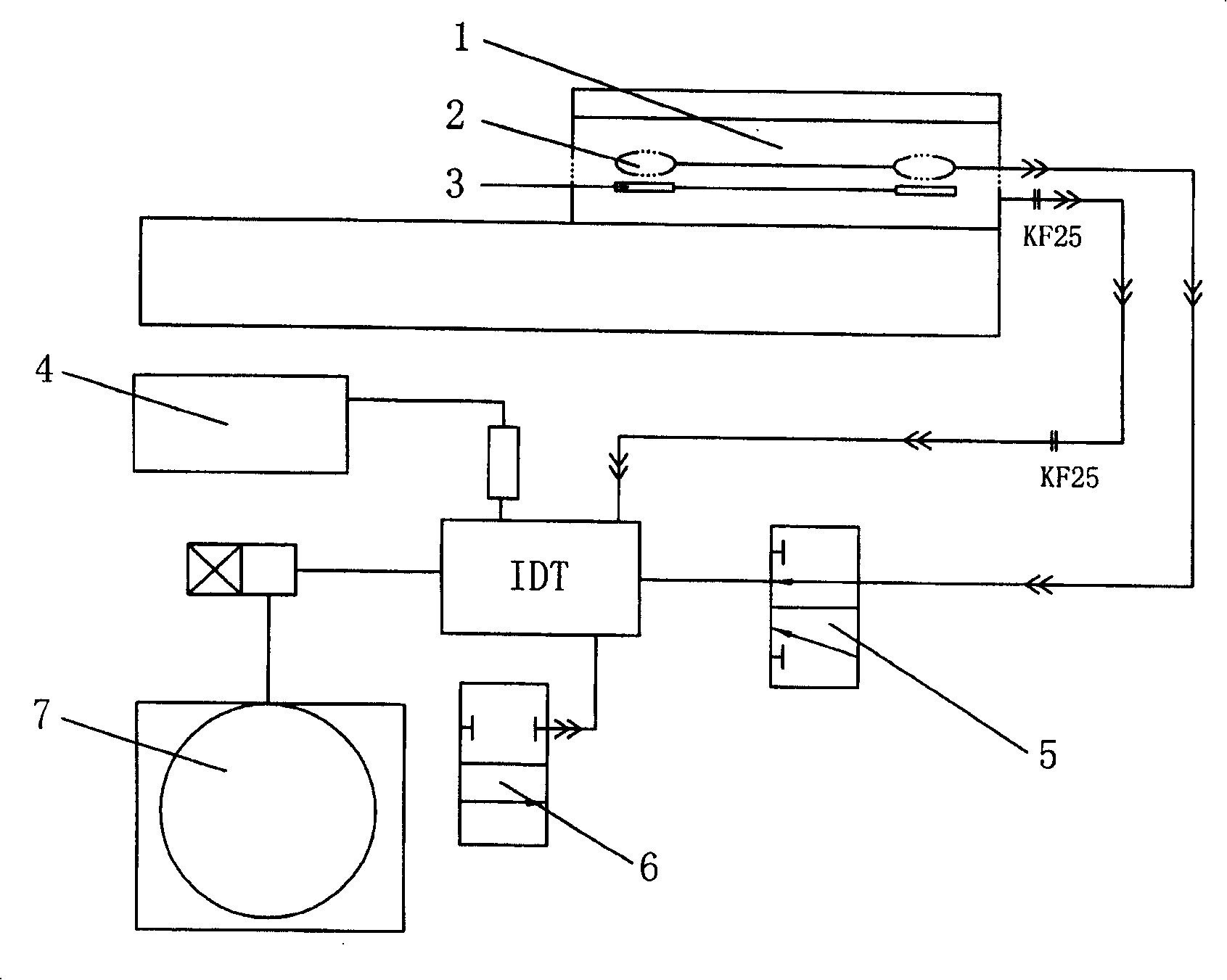

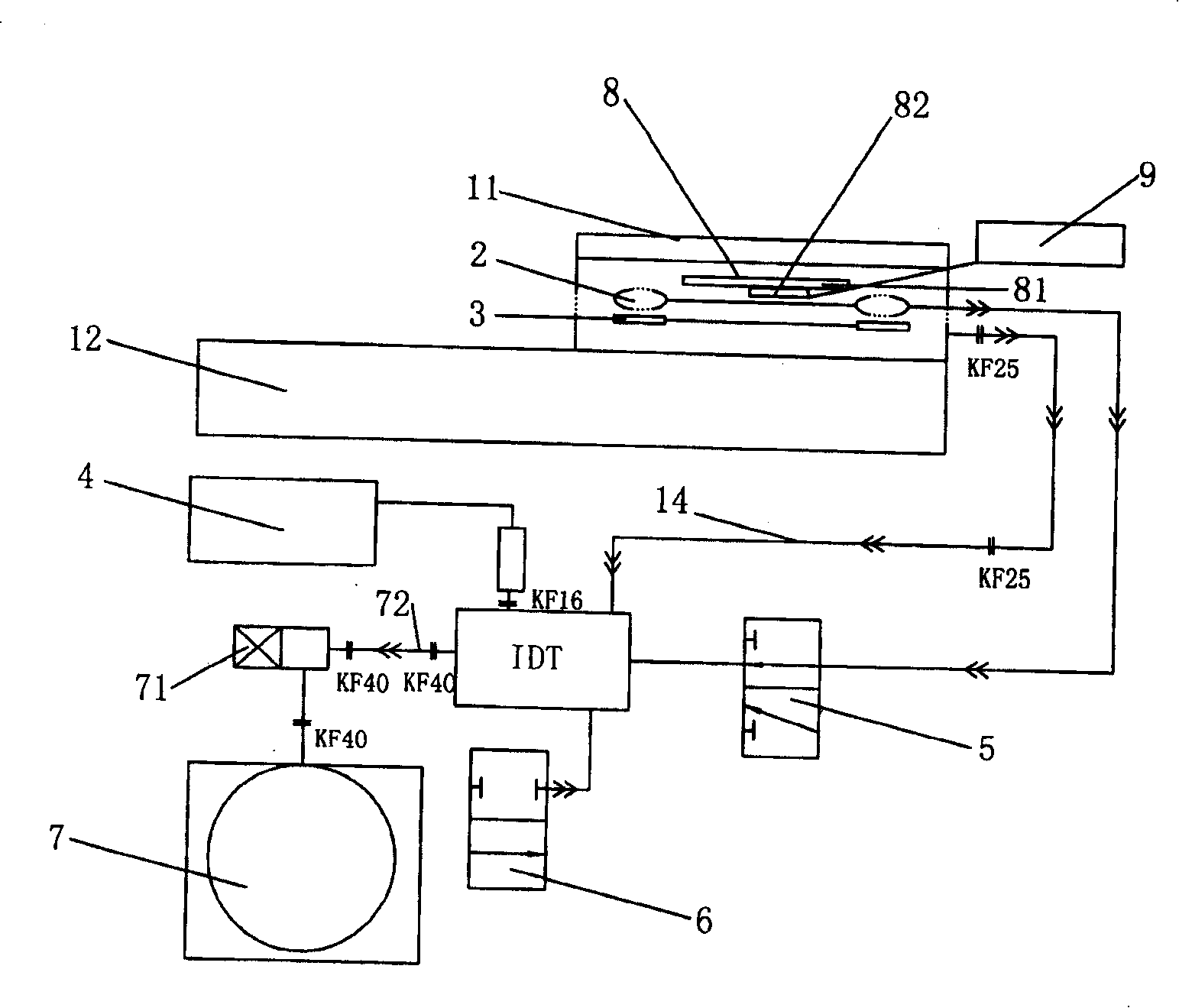

[0025] Such as figure 2 As shown, a high-vacuum packaging machine with a preheating device includes a vacuum chamber 1, a hot-pressed air chamber 2 located in the vacuum chamber, a heat-sealing strip 3 located below the hot-pressed air chamber 2, a vacuum gauge 4, and two-position three-way Solenoid valve IDT, heat-sealing valve 5, inflation valve 6 and vacuum pump 7; Above-mentioned equipment connection and working principle are the same with existing vacuum packaging machine, and vacuum chamber 1 comprises vacuum chamber 1 upper cover 11 and lower cover 12 and passes vacuum The valve 13 and the pipeline 14 are connected to one interface of the two-position three-way solenoid valve IDT, the hot press chamber 2 is connected to one interface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com