Oil-gas mixed flow technique for processing large segment plug flow in primary oil collecting and delivering process

A technology of oil and gas mixed transportation and slug flow, applied in separation methods, chemical instruments and methods, liquid degassing, etc., can solve problems such as waste of associated gas resources, potential safety hazards, and increased collection and transportation costs, so as to eliminate The effect of emptying loss, avoiding pump failure and prolonging the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

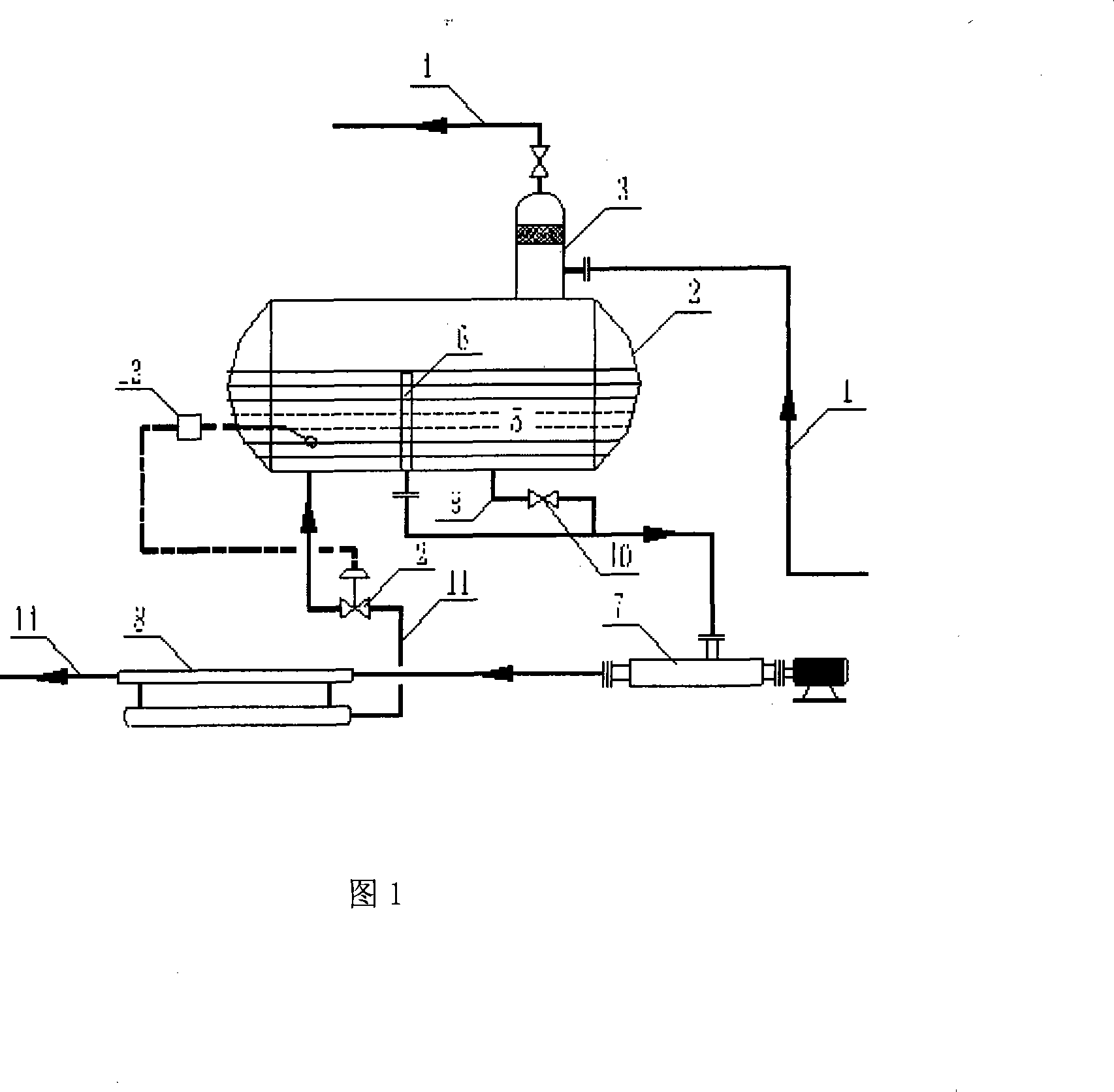

[0013] As shown in Figure 1, the oil-gas separation chamber 3 of the separation buffer device 2 communicates with the input oil-gas 1 through a pipeline, and the input oil-gas 1 enters the oil-gas separation chamber 3 of the separation buffer device 2 through the pipeline, and a part of the separated associated gas is released from the oil-gas separation chamber The associated gas output pipeline of 3 is transported to the input end of the process self-use fuel gas 4 as the process self-use fuel gas 4 . The oil separated by the oil-gas separation chamber 3 enters the liquid collection chamber 5 through the channel communicating with the separation buffer device 2 . There is an overflow outlet pipe 6 inside the separation buffer device 2, and the overflow outlet pipe 6 is connected to the input end of the oil and gas conveying screw pump 7, and the oil and gas conveying screw pump 7 is connected to the pipeline liquid separator 8, and the pipeline liquid separator 8 has external...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com