Electric motor with permanent magnet excitation and rotor cooling

A technology for exciting motors and permanent magnets, applied in electromechanical devices, cooling/ventilation devices, magnetic circuits, etc., can solve problems such as complex implementation, and achieve the effects of improving motor efficiency, increasing magnetic flux, and high anti-demagnetization stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

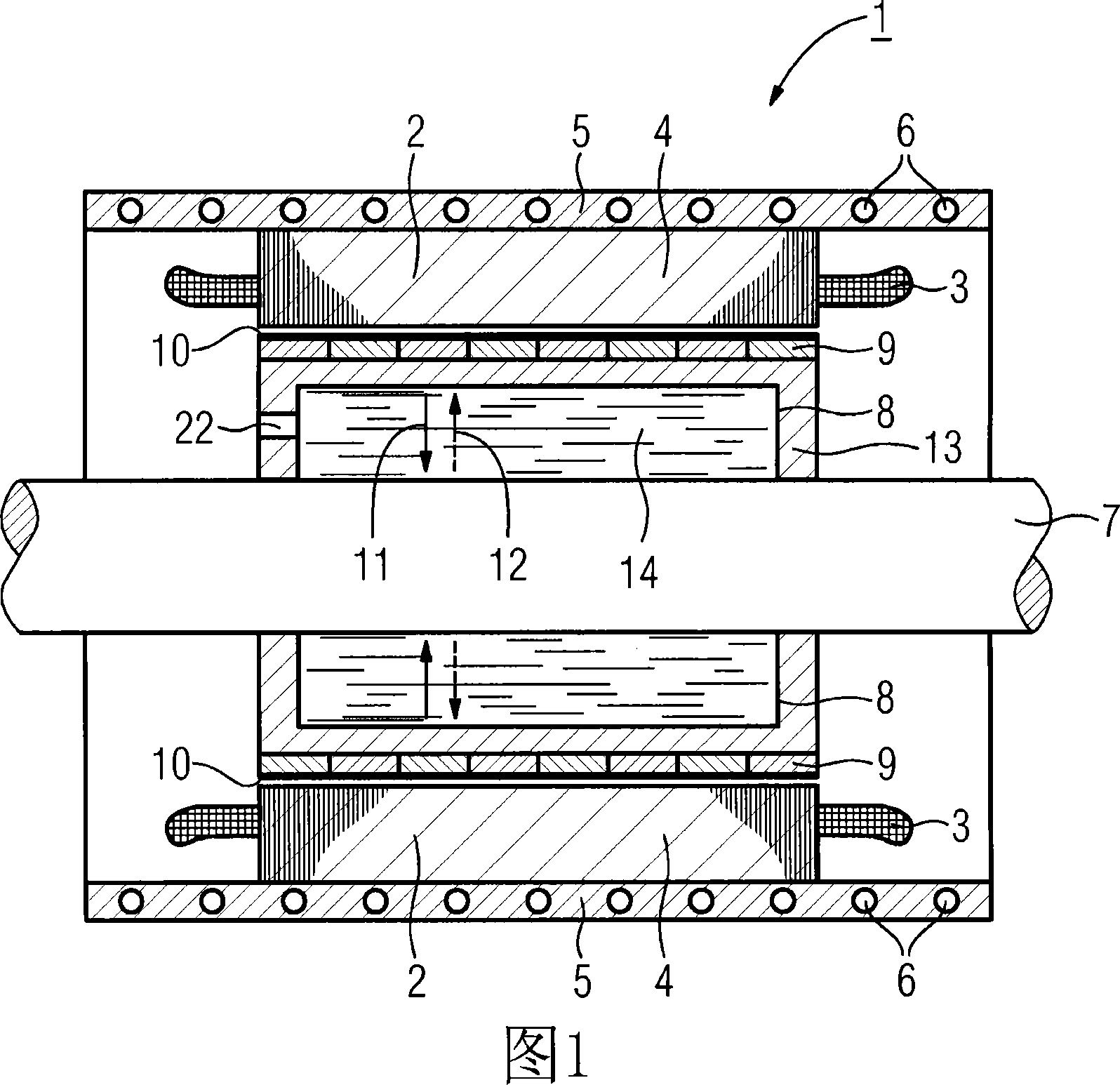

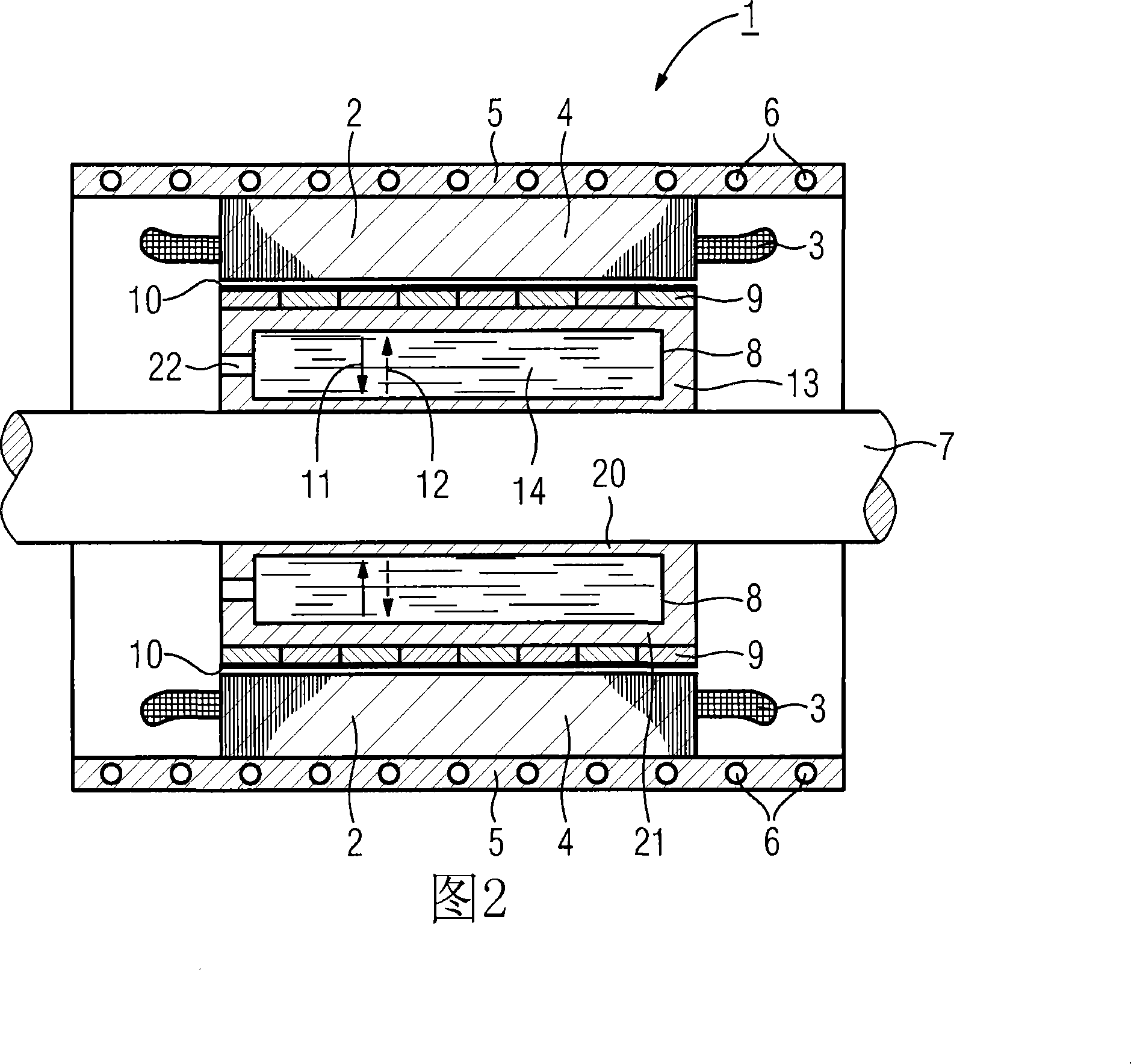

[0022] FIG. 1 shows a longitudinal section through a direct drive designed as a permanently excited synchronous machine 1 . This schematically represented permanent-magnet-excited synchronous machine 1 has a stator 2 consisting of laminated laminations 4 . Windings are arranged in slots (not shown in detail) of the stator 2 , which form end windings 3 on the end faces of the stator 2 . Most of the heat generated by these windings in the laminations 4 during the operation of the synchronous motor 1 is discharged from the stator through the heat dissipation sleeve 5 and the cooling medium (such as air or some kind of liquid) existing in the heat dissipation channel 6 . Wherein, the heat dissipation channel 6 extends around the stator 2 in a corrugated or helical shape.

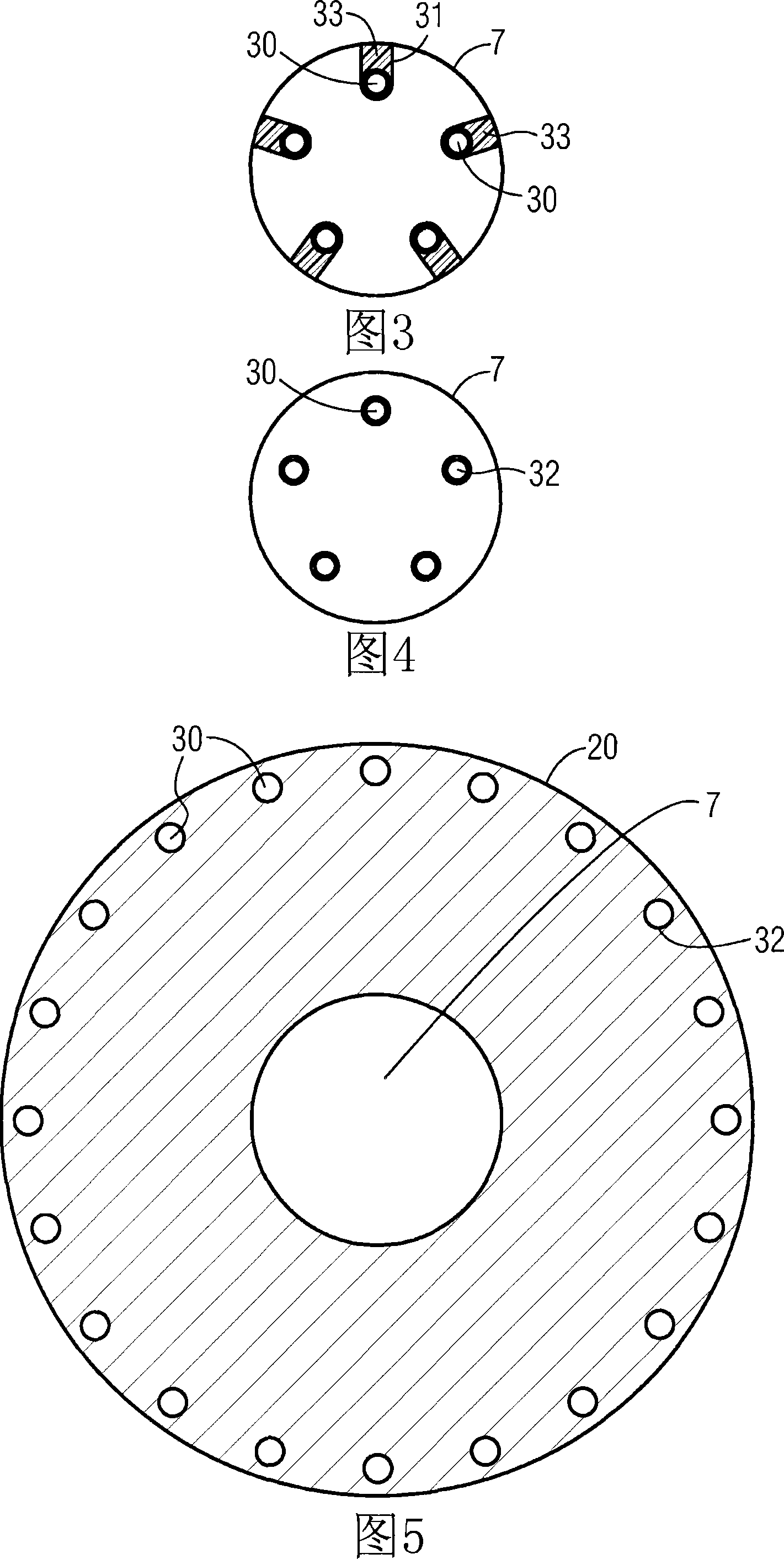

[0023] The rotor 8 has a hollow shaft 13 shrink-fitted with the output drive shaft 7 . On the air-gap side of the permanent-magnet synchronous machine 1 , the rotor 8 has a plurality of permanent magnets 9 , w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com