Variable angle electric iron

An electric soldering iron and angle technology, which is applied in the direction of soldering iron, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient welding work and affecting the quality of work, and achieve the effect of not easy to fatigue, light hand feeling, and convenient angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

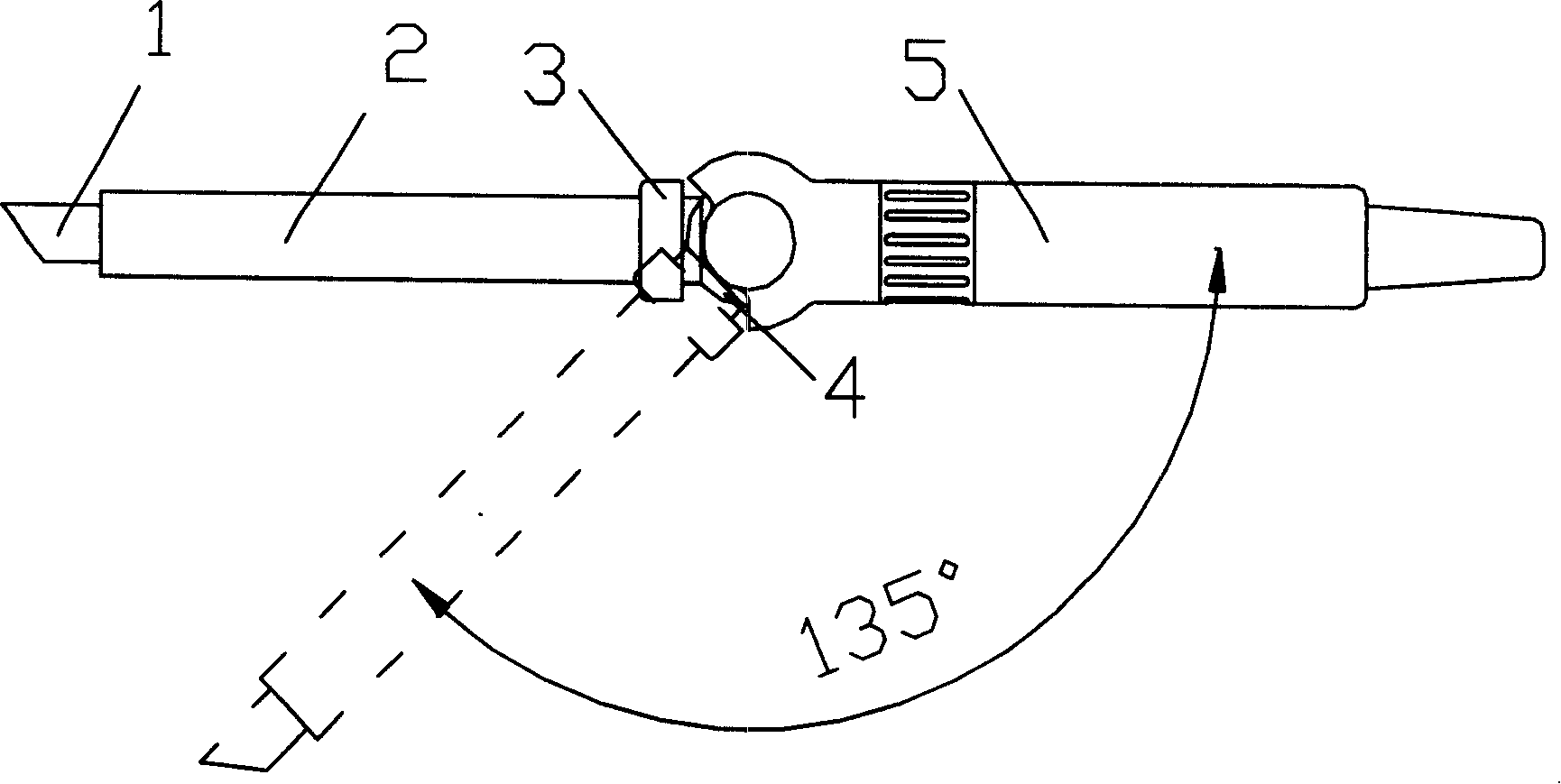

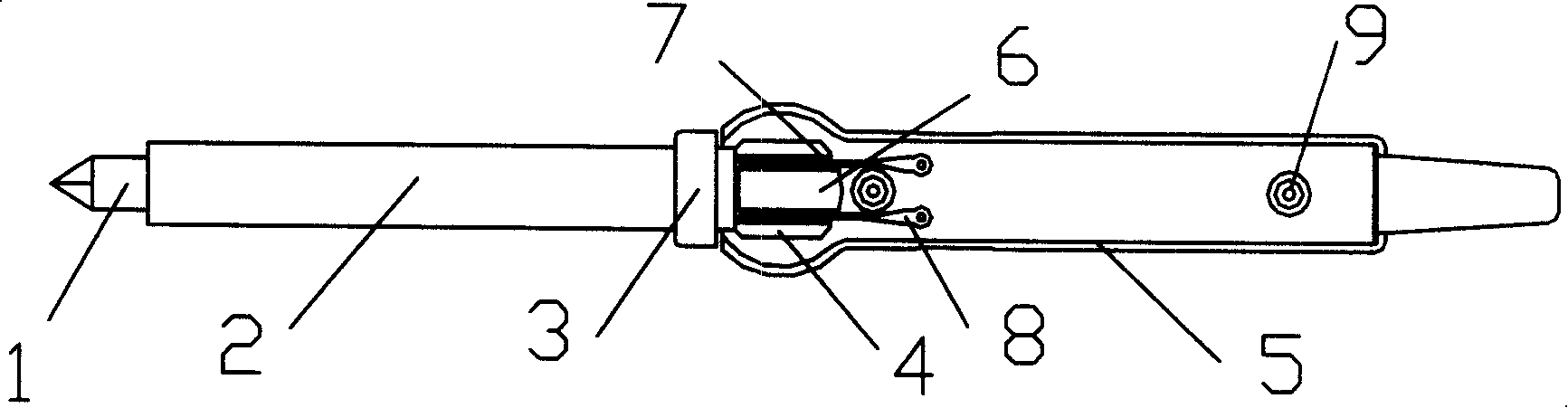

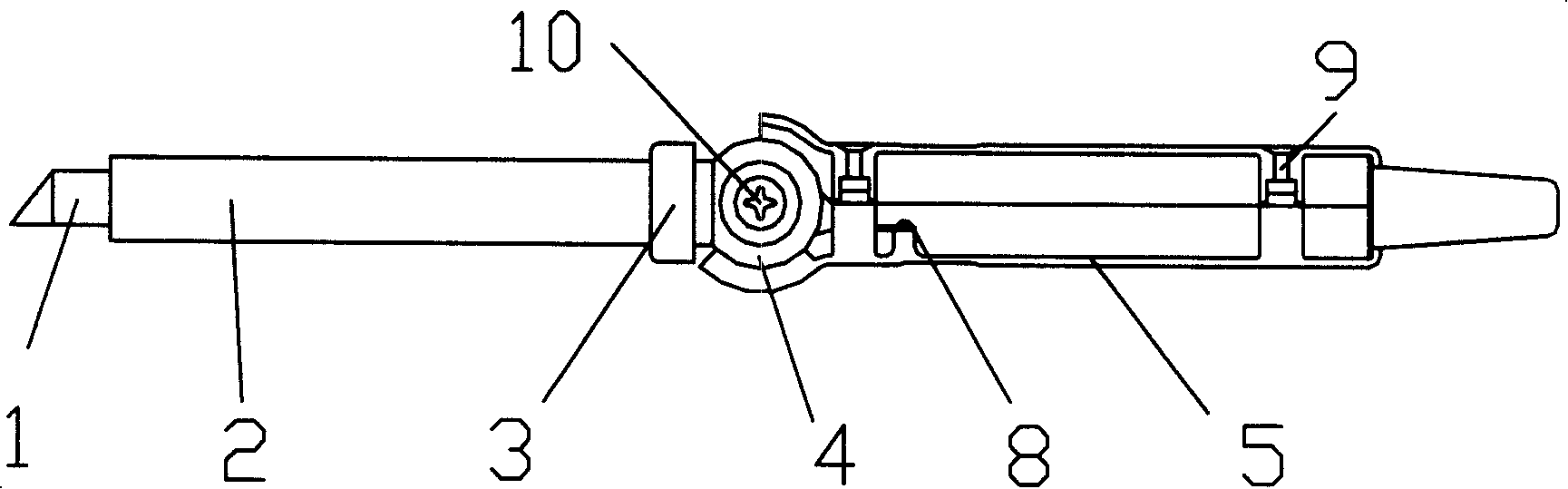

[0009] Examples: figure 1 , figure 2 , image 3 The variable angle electric soldering iron shown is composed of a soldering tip (1), a heating device (2), a lock nut (3), a ball head (4), a handle (5), a ball head post (6), and a heating tube lead ( 7), the outer lead (8), the handle fastening screw (9), the ball head fastening screw (10), the angle of the welding nozzle and the handle can be adjusted freely between 180 degrees and 135 degrees according to actual needs, the operator When using an electric soldering iron, it is more suitable for ergonomics requirements, and it feels lighter and more comfortable, and it is not easy to be fatigued for long-term operation. The invention adopts a ball joint connection between the handle and the heating device, and the power supply of the heating device is provided by the heating tube lead and the outer lead that are locked between the ball head and the ball head post. Therefore, the heat generated by the heating device cannot be direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com