Mechanism for unhitching and resetting worm wheel endless screw

A technology of worm gear and reset mechanism, which is applied in mechanical equipment, belts/chains/gears, portable lifting devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

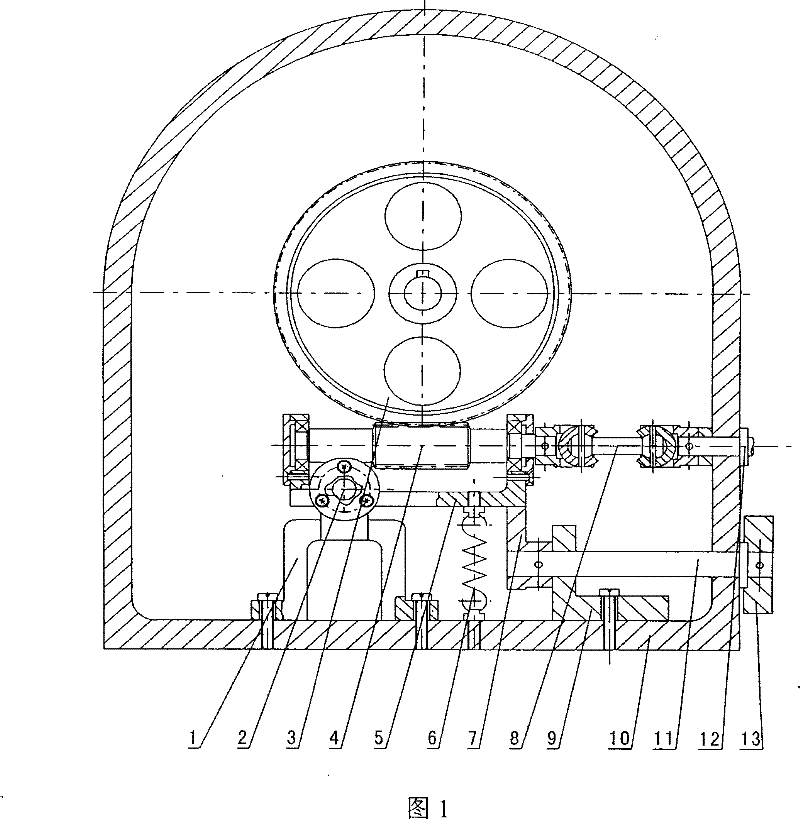

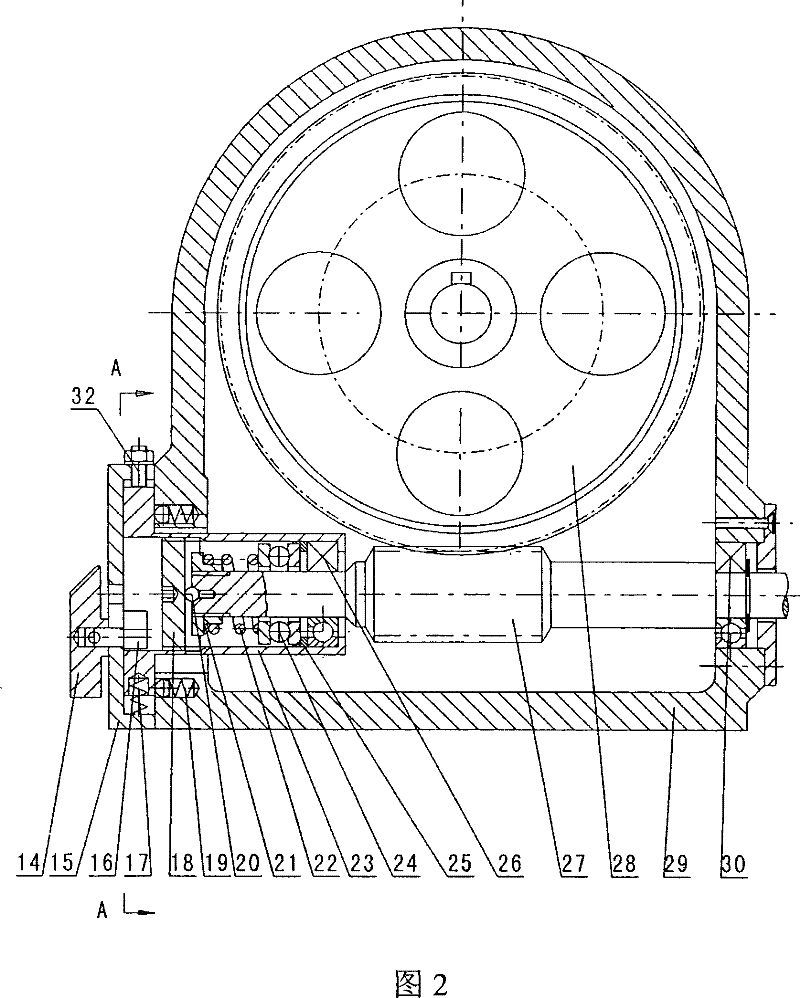

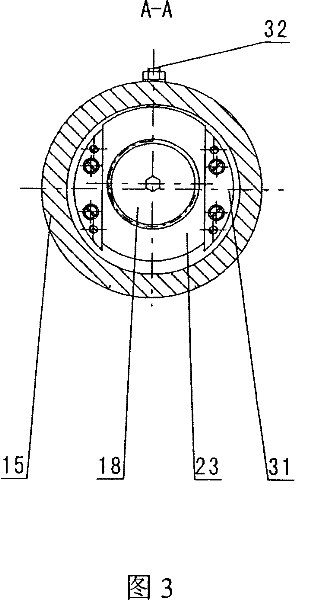

[0016] The invention according to figure 2 and image 3 The structure shown is implemented, and the material and technical requirements of the other parts: H62 is used for the hand twist 14; H62 is used for the limit cover 15; 45 steel is used for the cam 16; 65Mn is used for the radial top slide rail spring 17; GCr18 is used for the threaded top 18 Quenching treatment; steel ball 20 adopts GCr18, quenching hardness HRC 58~62; axial spring seat 21 adopts H62, worm axial spring 22 adopts 65Mn; slide rail sleeve 23 adopts H62; thrust ball bearing 24 adopts standard parts reformation; bearing The sleeve 25 adopts H62; the first radial ball bearing 26 adopts standard parts (this part may use self-aligning ball bearings); the worm 27 adopts 40Cr quenching and tempering treatment; the worm wheel 28 adopts tin bronze; Two radial ball bearings 30 adopt standard parts (this part or adopt self-aligning ball bearings); Guide rail 31 adopts H62; Limit screw 32 adopts 45 steel.

[0017]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com