Non-pump high volume water purifier

A high-flow, pure water machine technology, applied in water/sewage multi-stage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. Low problems, to achieve the effect of saving energy, increasing safety and reliability, and reducing machine costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

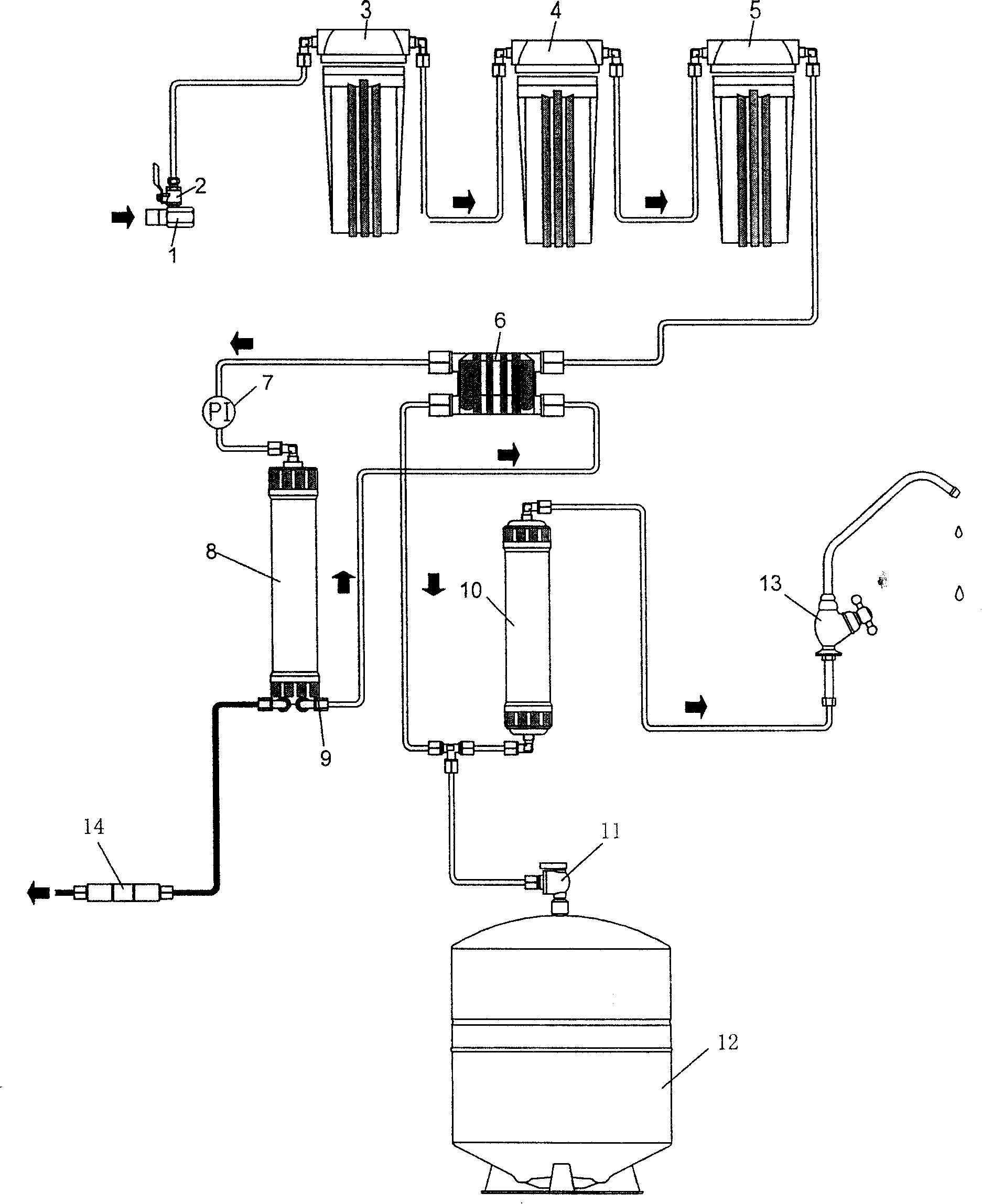

[0023] Such as figure 1 The shown pumpless high-flow pure water machine of the present invention includes a dust cover (not shown in the figure), water inlet tee 1, 2-point ball valve 2, 5 μm PP cotton filter 3, granular activated carbon filter 4, 1 μm PP cotton Filter 5, four-sided valve 6, pressure gauge 7, reverse osmosis filter 8, rear activated carbon filter 10, pressure water storage tank 12, water outlet tap 13 and waste water proportional regulator 14.

[0024] Wherein, the four-sided valve 6 has two water inlets and two water outlets, wherein one water inlet and one water outlet are respectively marked with IN symbols and OUT symbols, and the other water inlet and another water outlet are located at the aforementioned water inlet and outlet respectively. directly below the water outlet.

[0025] Water inlet tee 1, 2-point ball valve 2, 5μm PP cotton filter 3, and granular activated carbon filter 4 are connected in series in sequence, and the water outlet of granular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com