Micro-wave oven

A microwave oven and microwave emission technology, which is applied in the field of microwave ovens, can solve problems such as microwave distribution and uneven distribution that are not considered, only considered, and achieve the effects of preventing dead angle areas, improving microwave heating efficiency, and reducing anode temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

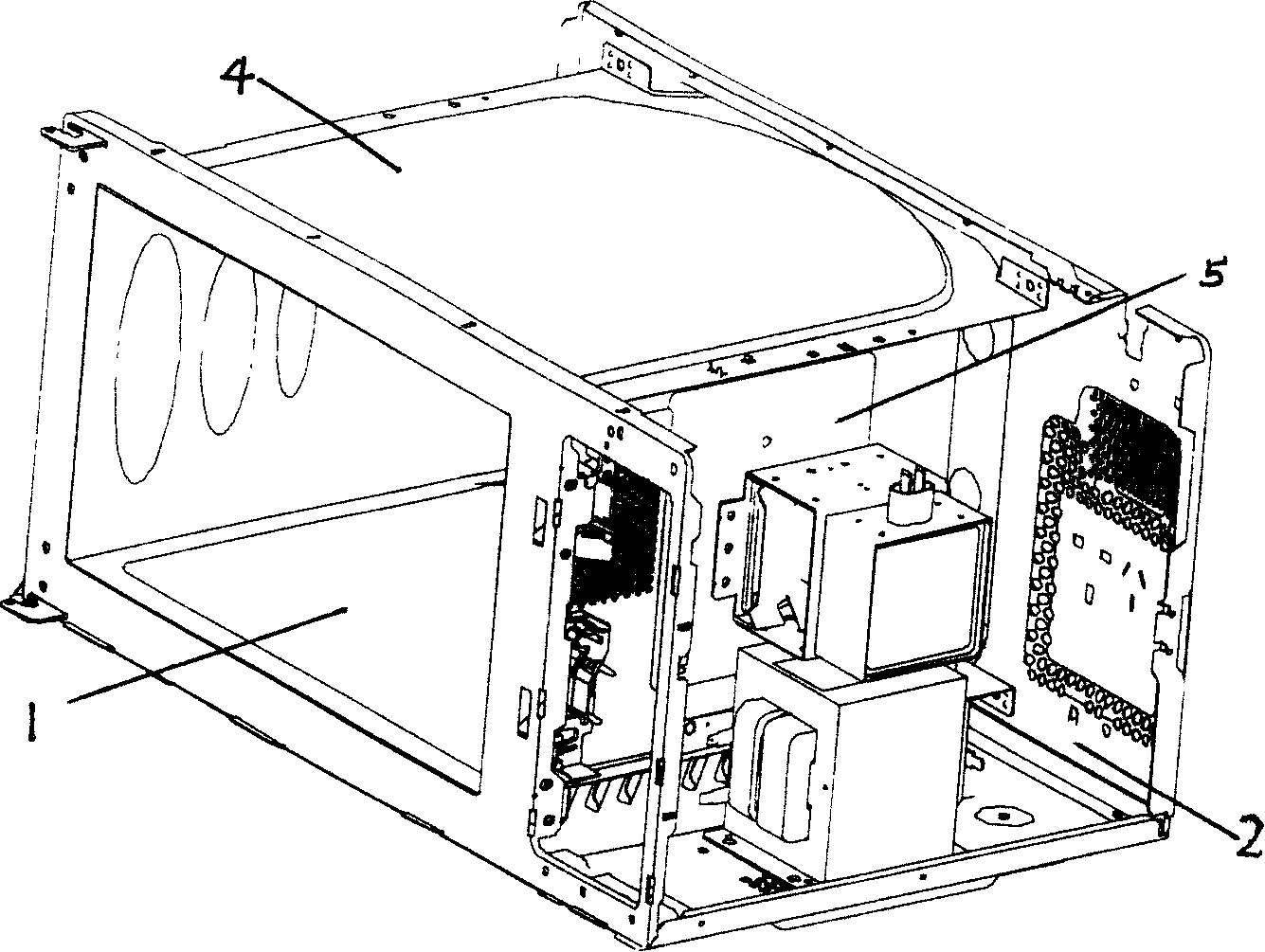

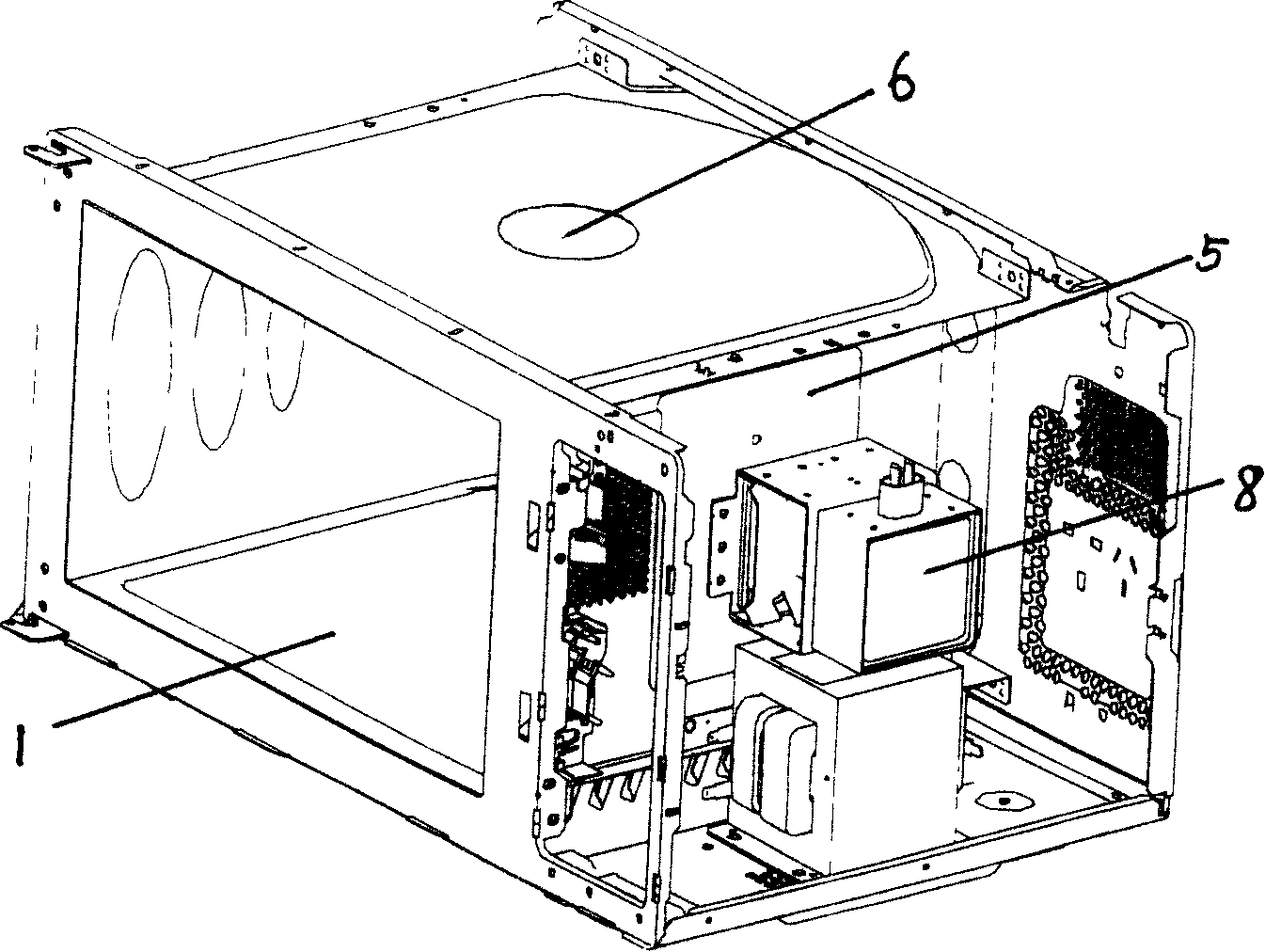

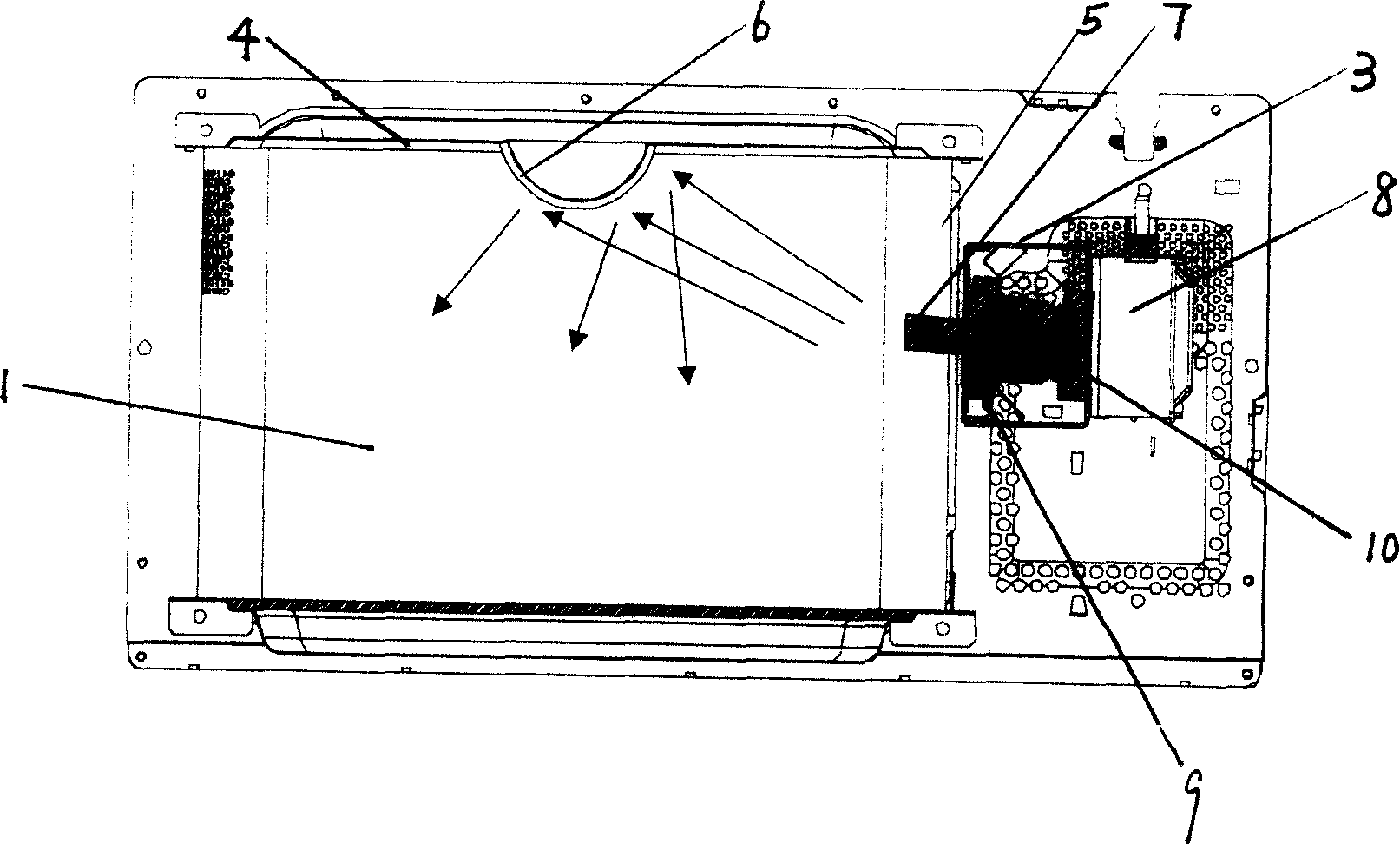

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0033] Such as figure 2 , 3 , 4, the microwave oven of the present invention includes a furnace chamber 1, a power distribution chamber 2, and a magnetron 8. A spherical surface 6 protruding to the inside of the furnace chamber 1 is formed on the furnace chamber loam cake 4, and the magnetron 8 is installed in the furnace chamber. On the cavity side plate 5 , the microwave transmitting antenna 7 on the magnetron 8 is aligned with the focal point of the spherical surface 6 .

[0034] The magnetron casing 3 that magnetron 8 is installed inside is installed on the furnace cavity side plate 5, and the magnetron support 9,10 in the magnetron casing 3 inner side is non-equal thickness, makes the magnetron casing 3 The microwave transmitting antenna 7 is inclined upwards.

[0035] The spherical surface 6 on the furnace chamber loam cake 4 is stampe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com