Laser emission axis and mechanical base level coaxiality measuring method based on secondary light source

A technology of coaxiality measurement and auxiliary light source, which is applied in the field of measurement and can solve the problems of measurement, beam divergence angle, small pointing control accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

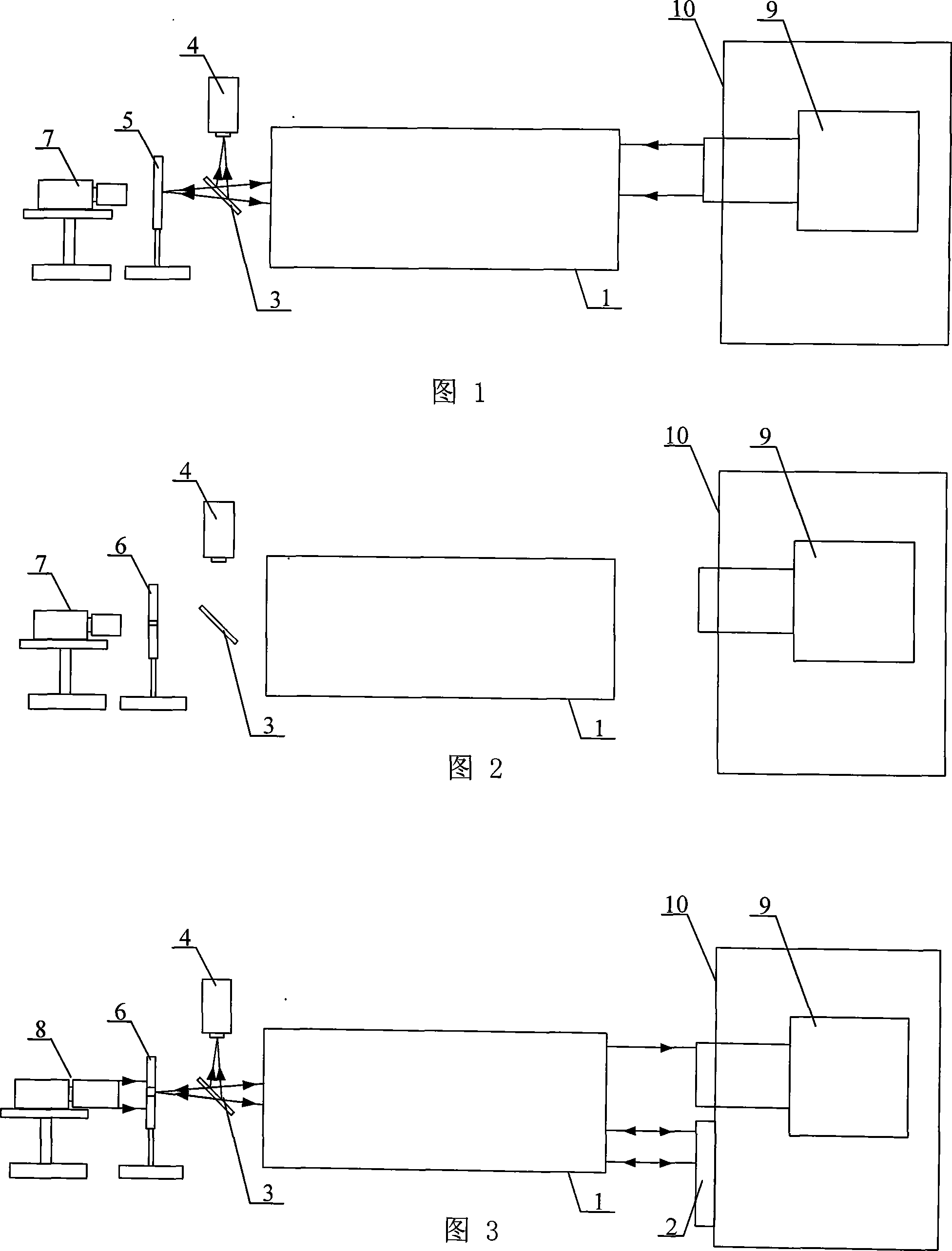

[0013] Specific implementation mode 1: This implementation mode is described in conjunction with FIGS. 1 to 5. The steps of this implementation mode are as follows:

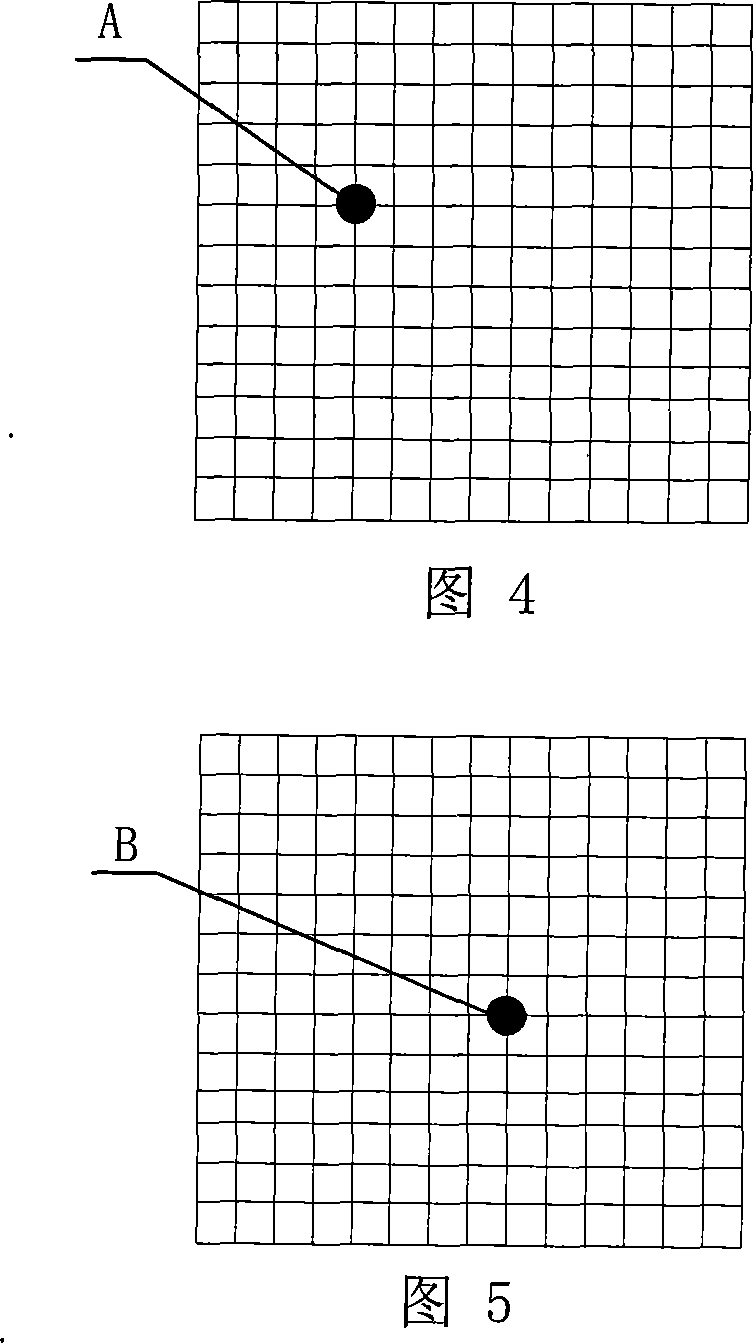

[0014] Step 1: Detect the exit spot of the laser emission system 9 under test: the laser emission system 9 under test emits a laser beam, the laser beam is focused by the telephoto collimator 1, and after focusing, the measured laser beam is irradiated on the light outlet of the telephoto collimator 1 On the 1:1 beam splitter 3 between the focal point, 50% of the measured laser beam is reflected by the beam splitter 3 and focused on the CCD detector 4, and the position of the imaging spot is recorded as A(x 1 ,y 1 ), another 50% of the measured laser beam forms a point image on the imaging screen 5, and the spot position is recorded by the microscopic CCD detector 7;

[0015] Step 2: Install the pinhole diaphragm: turn off the laser emitting system, remove the imaging screen 5, replace the shading plate 6 with t...

specific Embodiment approach 2

[0020] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the center position of the small hole of the light shielding plate 6 is adjusted in the step 2, and the small hole is placed at the focal plane of the telephoto collimator 1. The CCD detector 7 monitors the position of the center of the pinhole while the position of the CCD detector 7 remains unchanged, and adjusts it at the same time so that the center of the pinhole of the shading plate 6 coincides with the position of the imaging spot of the emitted light path of the measured laser emitting system 9 . Other components and steps are the same as those in Embodiment 1.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 in that the telephoto collimator 1 has a focal length of 12 m and an aperture of 400 mm. Other components and steps are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com