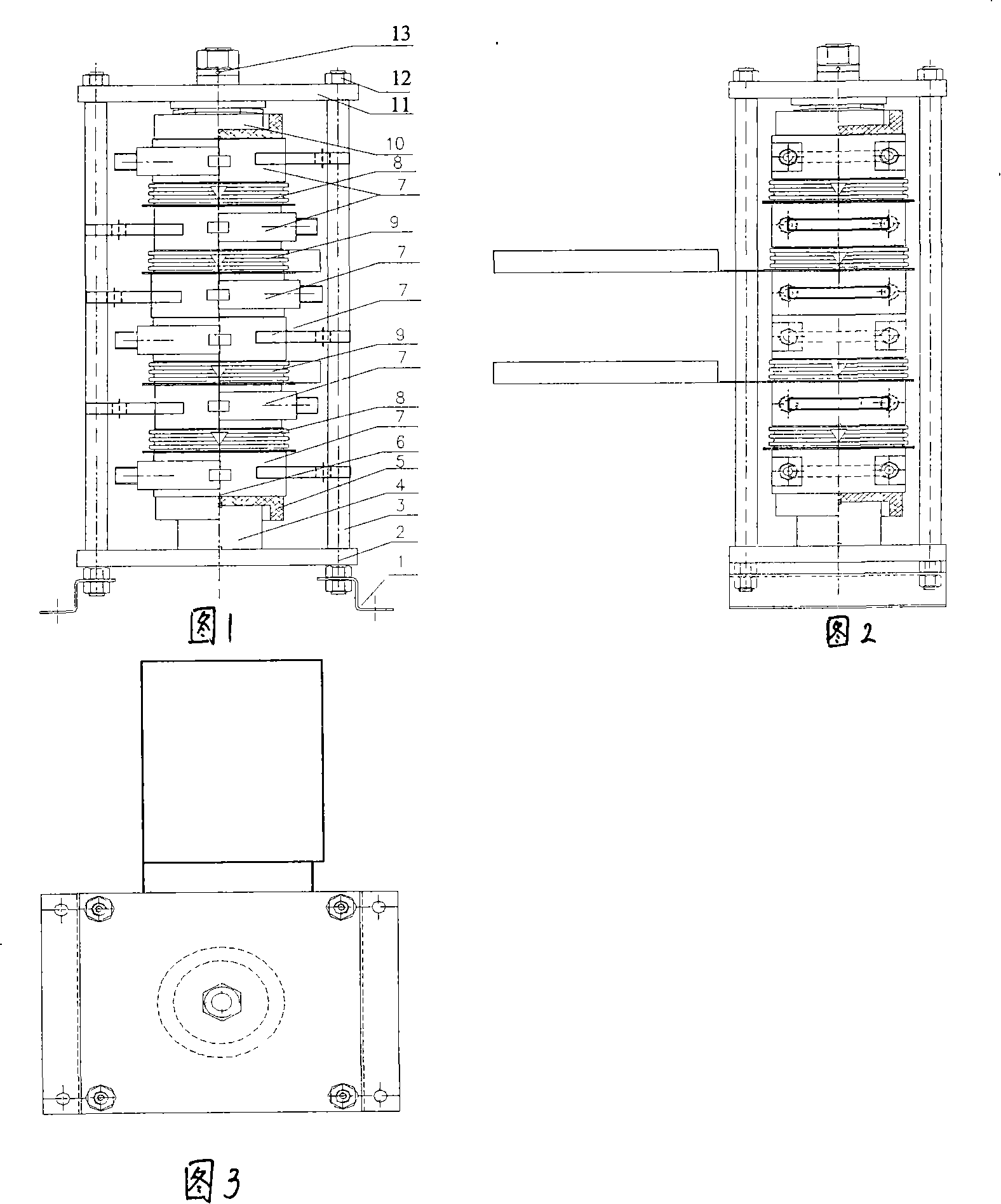

Press-loading valve stack for large power all-controlled semiconductor device

A technology for power devices and press-fit valves, applied in the field of press-fit valve stacks, can solve problems such as the difficulty of press-fit methods, and achieve the effects of simple press-fit, uniform force on devices, and improved insulation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The site requirements must meet the conditions. First, the frame of the device is combined with the bottom and the screw in order, and then the power device and the radiator are arranged in series, and the positioning pins are used between the two devices. It comes with its own positioning pins), but in the middle of the two power devices in the middle are two heat sinks in opposite directions. There is an insulating pad at both ends of the device arrangement (its insulation degree determines the voltage insulation degree of the entire device), at the bottom is a lower assembly with two planes with variable relationship, and at the top is a multi-layer disc The upper support of the shaped spring (after being pressed, the stress generated by it is used to achieve the purpose of the pressing force of the element). The outer sides of the lower support and the upper support are respectively a lower spring plate and an upper spring plate, and a positioning pin is also arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com