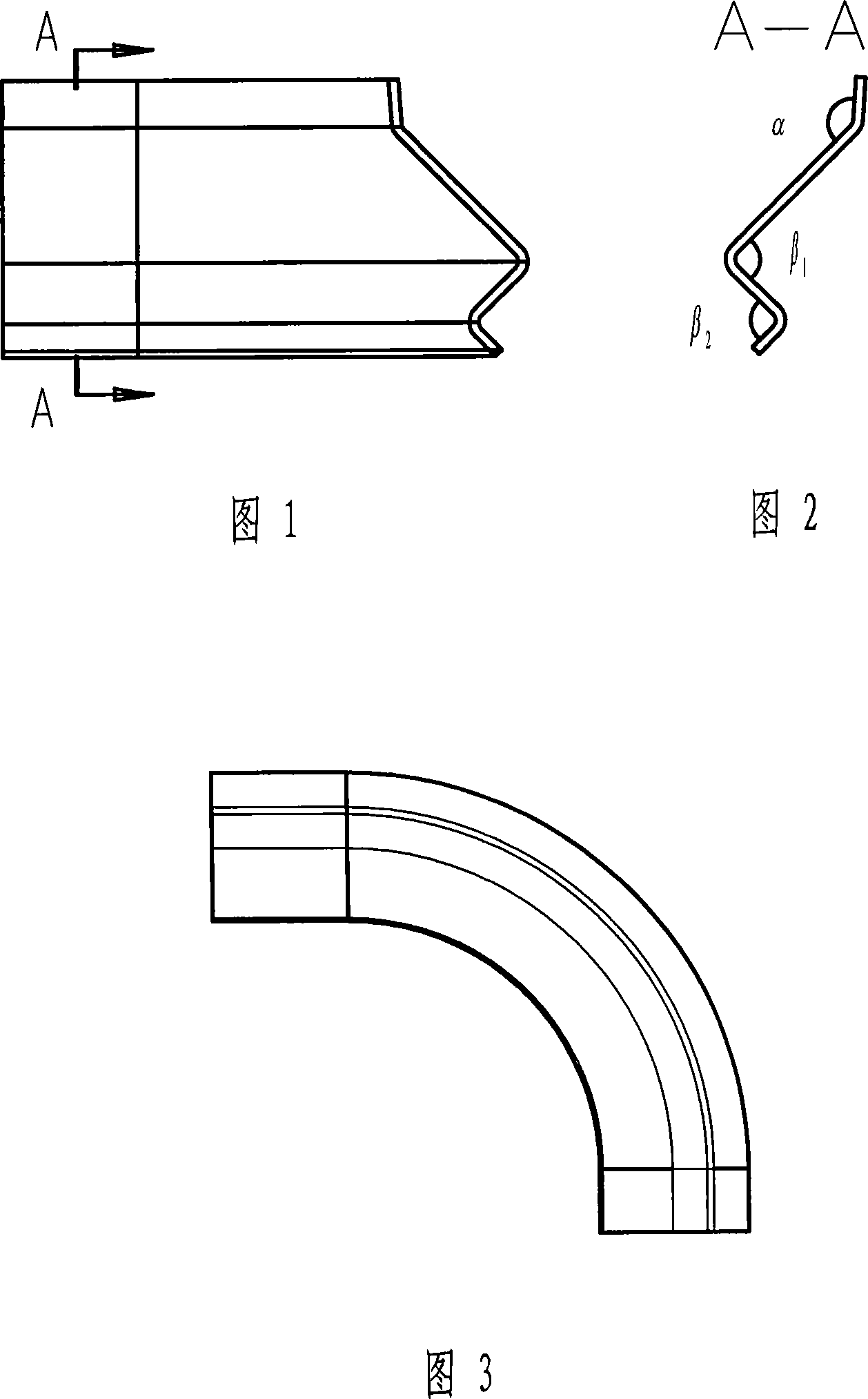

Railway carriage angle part window eaves shaping mold

A technology for railway passenger cars and forming molds, applied in forming tools, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of difficulty in ensuring consistency, complex structure, uneven stress distribution of workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

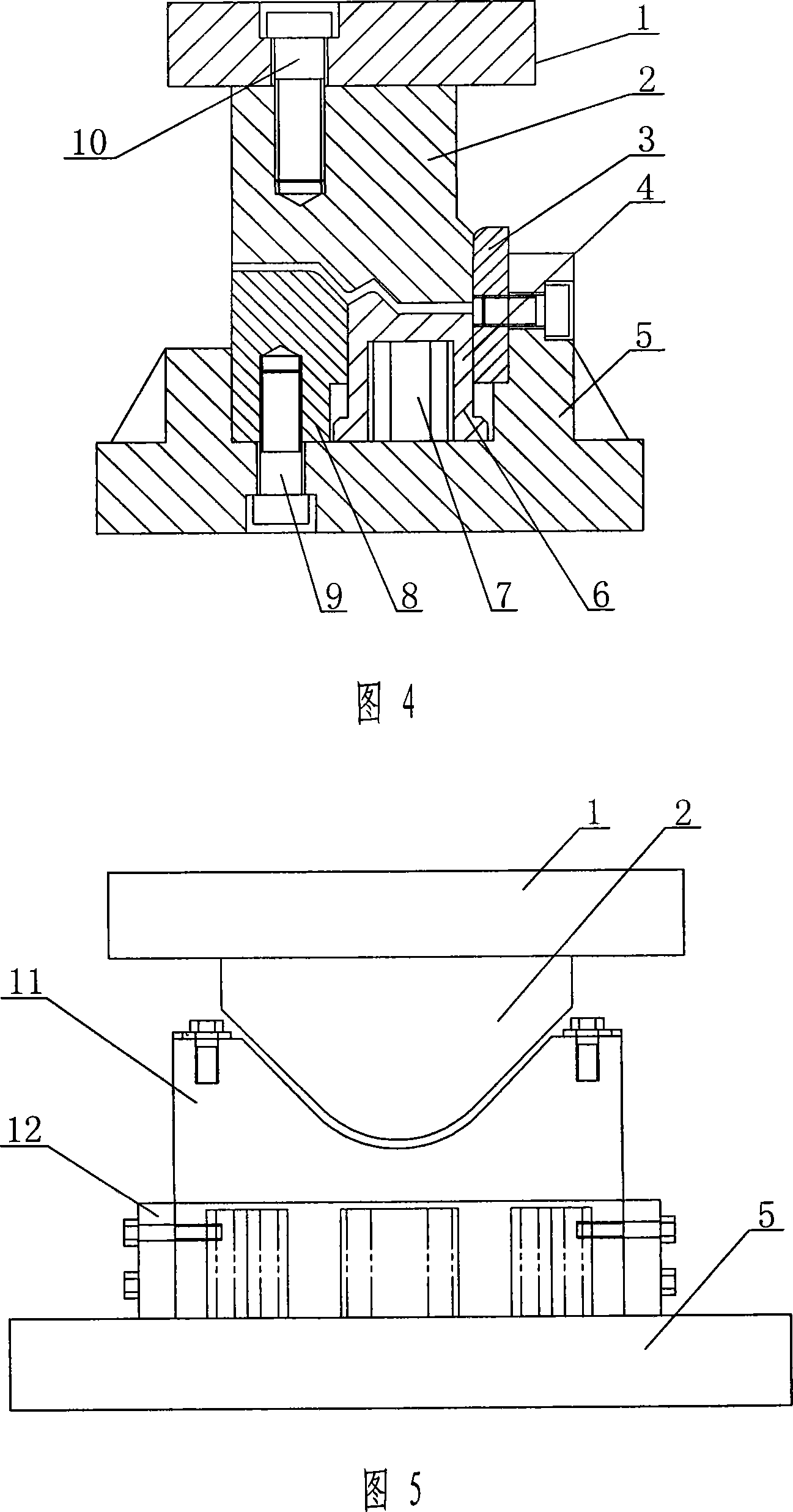

[0014] The present invention will be further described in detail below with reference to the accompanying drawings and examples. However, the invention is not limited to the examples given.

[0015] As shown in Fig. 4 and Fig. 5, the composition of the cornice molding mold at the corner of the railway passenger car of the present invention comprises a lower mold (i.e. a fixed lower mold 8) fixedly connected with the lower mold base 5 by screws 9, and is fixed with the template 1 by screws 10 Connected upper mold 2, the lower mold is composed of a fixed lower mold 8 arranged longitudinally, an elastic lower mold 6 and a rectangular spring 7 thereof, and the rectangular spring 7 is placed in the slot on the back of the elastic lower mold 6 on the lower mold base 5 Middle; the longitudinal outer side of the elastic lower mold 6 is provided with the side plate 3 fixedly connected with the lower mold base 5 by screws 4; ; The interface between the fixed lower die 8 and the elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com