Single slideway sleeve barrel mechanical arm

A manipulator and mechanical arm technology, applied in the field of manipulators, can solve the problems of heavy weight, difficult wiring, high energy consumption, etc., and achieve the effects of large lifting stroke, compact structure and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in more detail below in conjunction with accompanying drawing example:

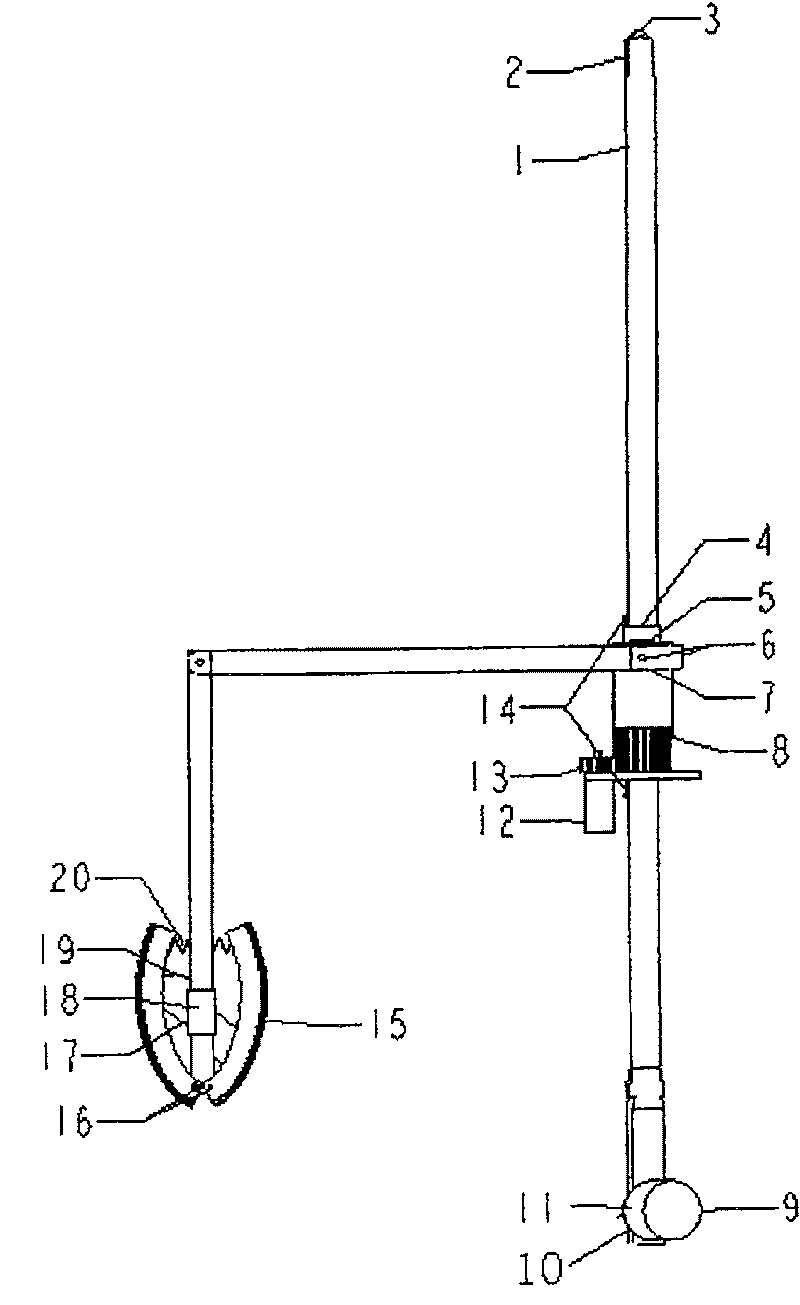

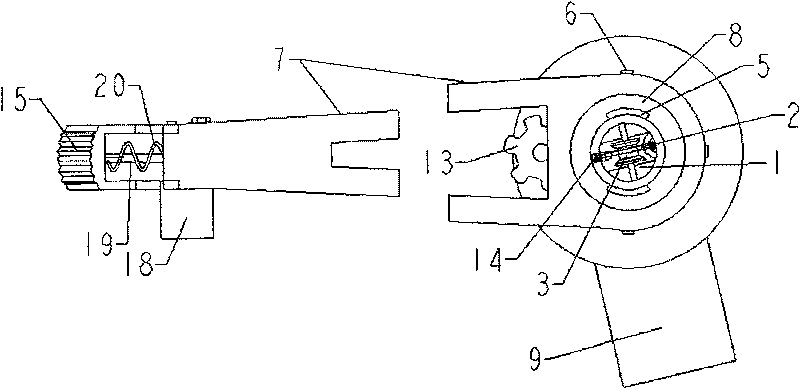

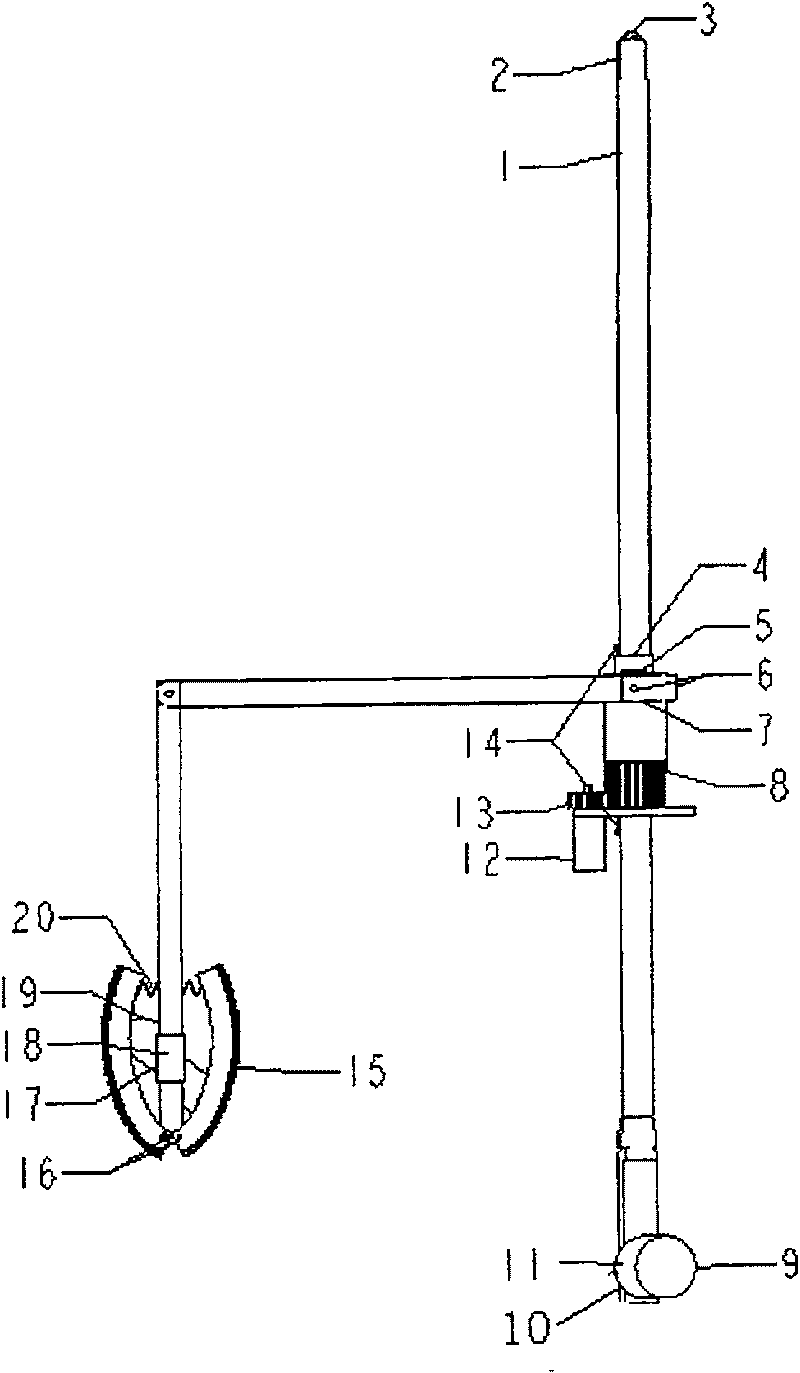

[0014] combine figure 1 with figure 2 , The composition of the single-slide sleeve manipulator includes slideway 1, steel wire rope 2, fixed pulley 3, inner sleeve 4, limit scraper 5, limit pin 6, mechanical arm 7, outer sleeve 8, winding motor 9 , coupling 10, reel 11, rotating motor 12, driving gear 13, connecting screw 14, pawl 15, rotating pin 16, steering gear coupling 17, steering gear 18, cam 19 and rubber band 20. The single-rod slideway 1 is grooved on both sides, and the inner sleeve 4 with a convex key is installed on it. The cooperation between the convex key and the groove can completely limit the circumferential movement of the inner sleeve relative to the slideway; the inner sleeve 4 is installed outside The outer sleeve 8, the boss of the inner sleeve 4 and the limit scraper 5 can completely restrict the relative movement of the outer sleeve 8. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com