Device and method for preparing carbon/carbon composite material with gradient distribution density

A carbon composite material and gradient distribution technology, which is applied in the field of devices for preparing carbon/carbon composite materials, can solve the problem of insignificant gradient distribution characteristics and achieve the effect of small dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

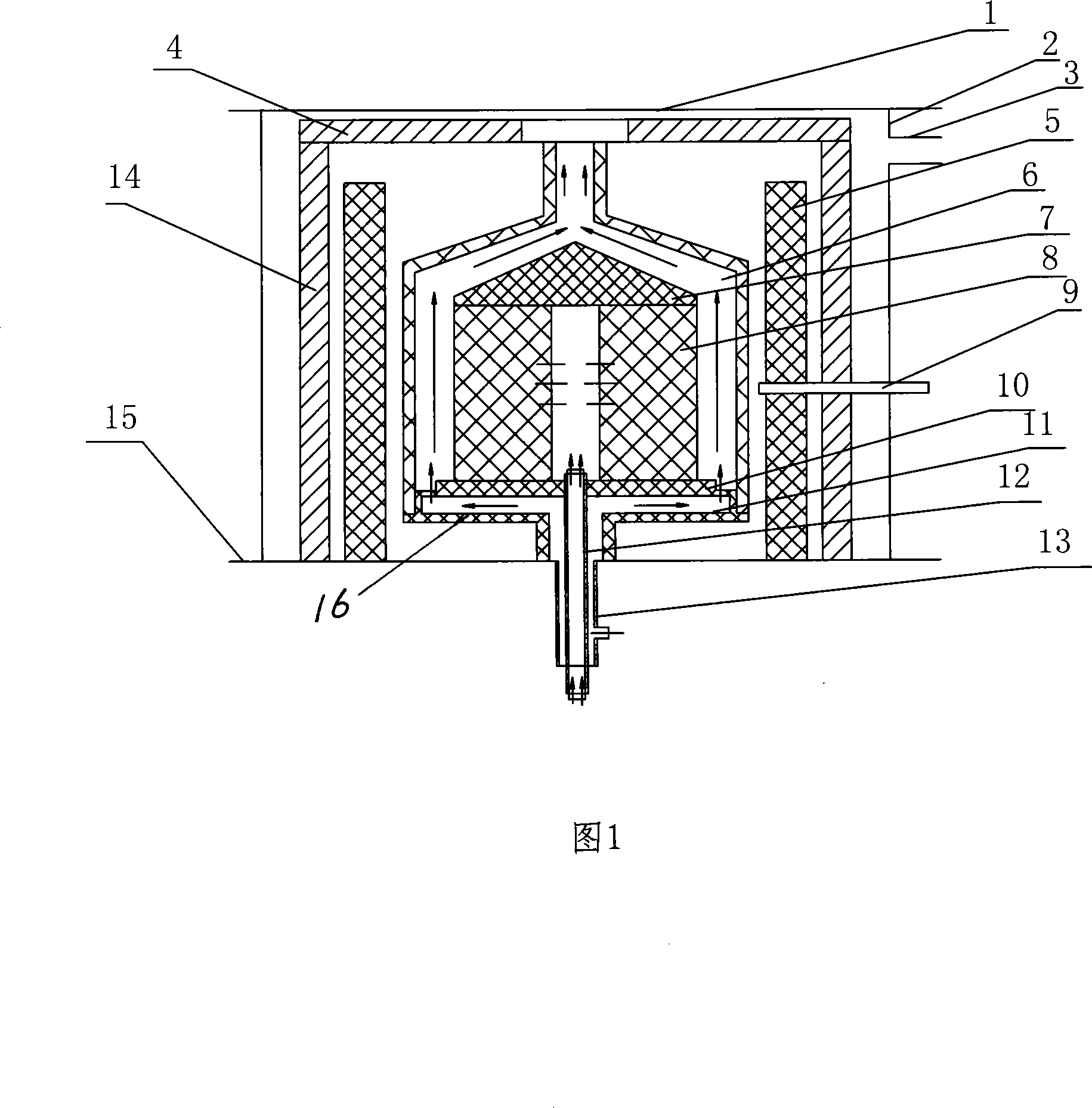

[0025] As shown in Figure 1, a device for preparing a carbon / carbon composite material whose density is distributed in gradients comprises a chemical vapor infiltration furnace body 2, a furnace cover 1 and a furnace bottom cover 15, and the upper part of the furnace body 2 is provided with a vacuum The air inlet 3, the furnace body 2 is provided with a thermal insulation blanket 14 and a thermal insulation cover plate 4, the thermal insulation blanket 14 is provided with a graphite heating element 5, and the inner part of the graphite heating element 5 is equipped with a graphite gas collector 16, so The graphite gas collector 16 is provided with a perforated cover plate 10 for the air distribution chamber to be infiltrated with the prefabricated body 8, and the upper part of the graphite gas collector 16 is located at the perforated cover plate 10 of the gas distribution chamber. The lower part of the perforated cover plate 10 of the gas distribution chamber is a gas distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com