Chamber type limit self-tightening type seal

A self-tightening and limiting technology, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problem of poor self-limiting and positioning functions of box-type sealing devices, reducing the reliability of box-type equipment and the convenience of operation. It can reduce the processing difficulty and processing requirements, the structure is simple, and the processing requirements are low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

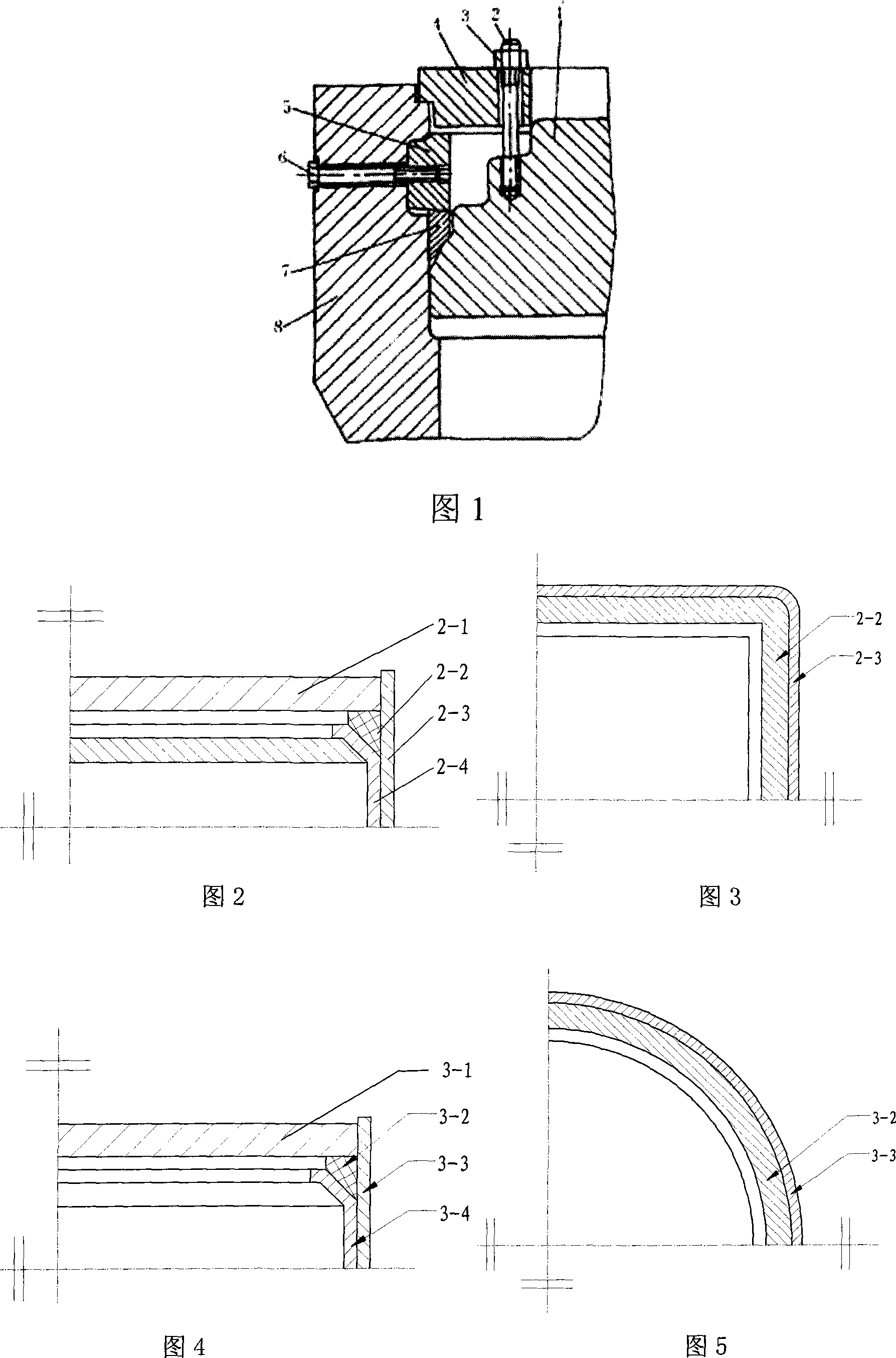

[0023] Embodiment 1: In Fig. 2, the mechanical contact surface 2-1, the trapezoidal gasket 2-2, the mechanical outer shell 2-3, and the "Y" shaped waist strip 2-4. There is a right-angle "Y" groove on one flange face of the flange pair, a trapezoidal gasket, and the trapezoidal gasket is located in the right-angle "Y" groove of the flange. The other flange surface of the flange pair is a plane, and the right-angle "Y" groove on the flange surface is processed by a conventional milling machine. The mechanical housing is a square box, and the trapezoidal gasket corresponds to the square box.

Embodiment 2

[0024] Embodiment 2: The other flange surface of the flange pair is a curved surface, and the right angle "Y" groove on the flange surface is welded or spot welded with a flat plate and a matching "Y" waist strip. Others are the same as embodiment 1, omitted.

Embodiment 3

[0025] Embodiment 3: In Fig. 3, the mechanical contact surface 3-1, the trapezoidal gasket 3-2, the mechanical outer casing 3-3, and the "Y" shaped waist strip 3-4. The mechanical housing is a round box, and the trapezoidal gasket corresponds to the round box. Others are the same as embodiment 1, omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com