Liquid pipeline packaged type connecting method and its device

A liquid pipeline and connection method technology, applied in the direction of pipes/pipe joints/fittings, pipes, branch pipelines, etc., can solve the problems of complex structure, inconvenient manufacturing and installation, etc., and achieve improved mechanical strength, convenient installation and construction, and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

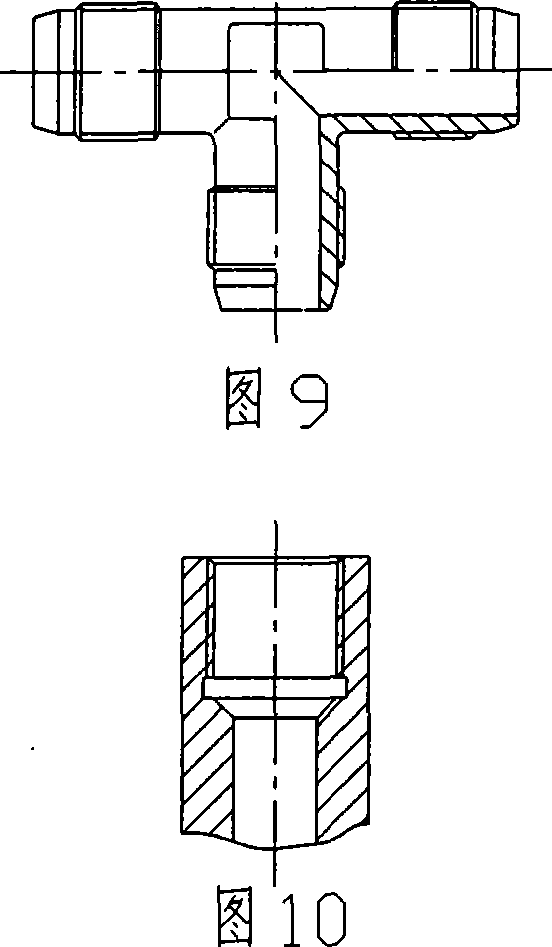

[0034] Liquid pipe sleeve connection method, the liquid main pipe is drilled out of the hole, and the platform is milled out around the drilled hole. The connecting head of the main pipe is set, and the connecting head and the branch pipe are connected by threads. Gaskets are used to seal the connection between the branch pipe and the main pipe hole. The branch pipe and the main pipe are sealed and connected with the corresponding hole of the main pipe through the sleeve connector to realize the communication between the branch pipe and the main pipe.

Embodiment 2

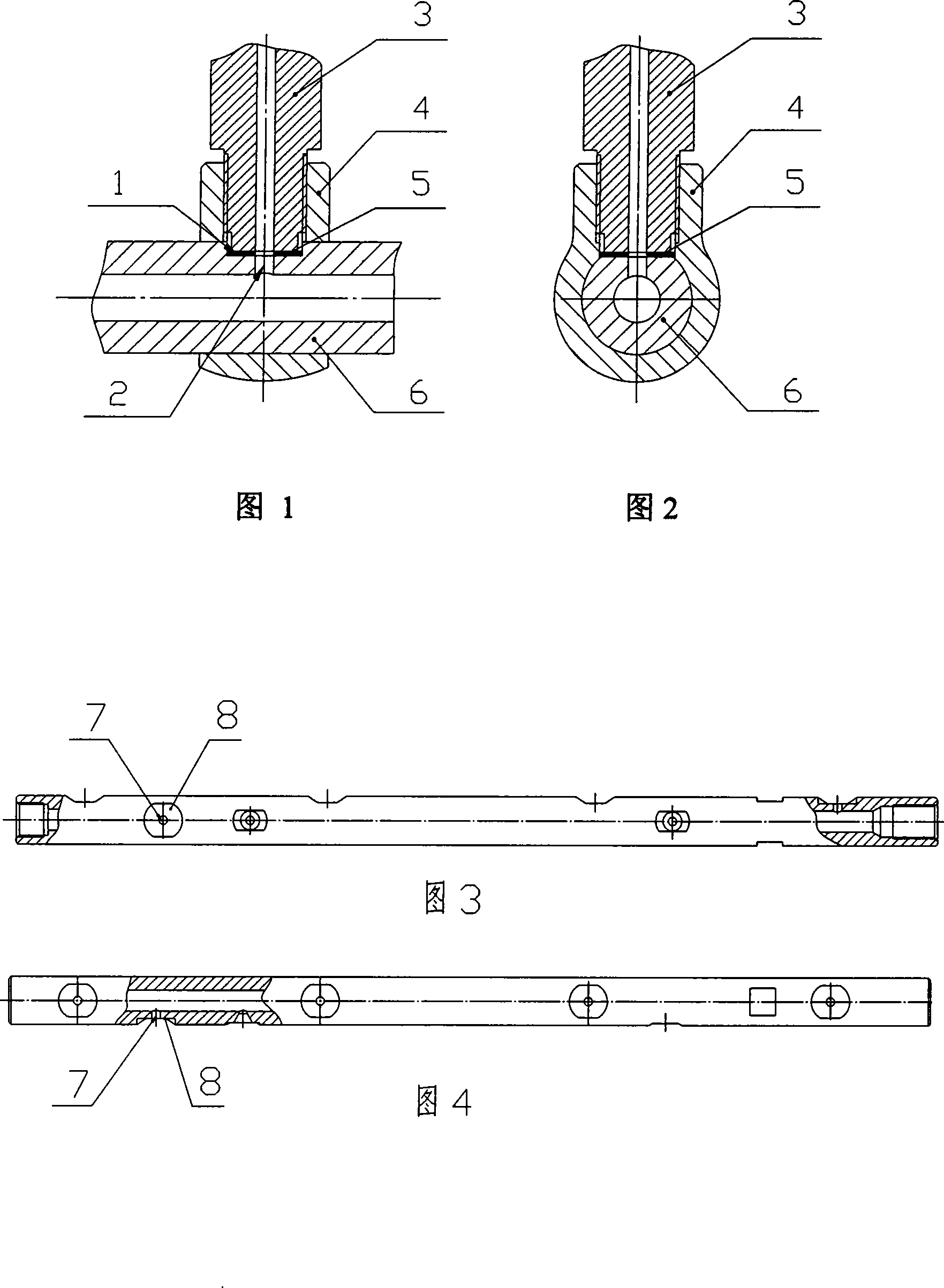

[0036] See Figures 1 and 2. The liquid pipeline set connection device has a milling platform 1 on the outer circle of the main oil pipe 6, and an oil hole 2 is drilled on the platform 1. The branch pipe 3 and the main oil pipe 6 are connected by a sleeve joint 4, and the sleeve joint 4 is set on the On the main oil pipe 6, the sleeve joint 4 and the branch pipe 3 are connected in a threaded structure. A sealing gasket 5 is installed between the branch pipe and the main pipe hole. The sleeve connector connects the branch pipe with the corresponding sealing fitting of the main pipe hole.

Embodiment 3

[0038] The application of the liquid pipeline sleeve connection on the high-pressure common rail pipe of the EFI diesel engine.

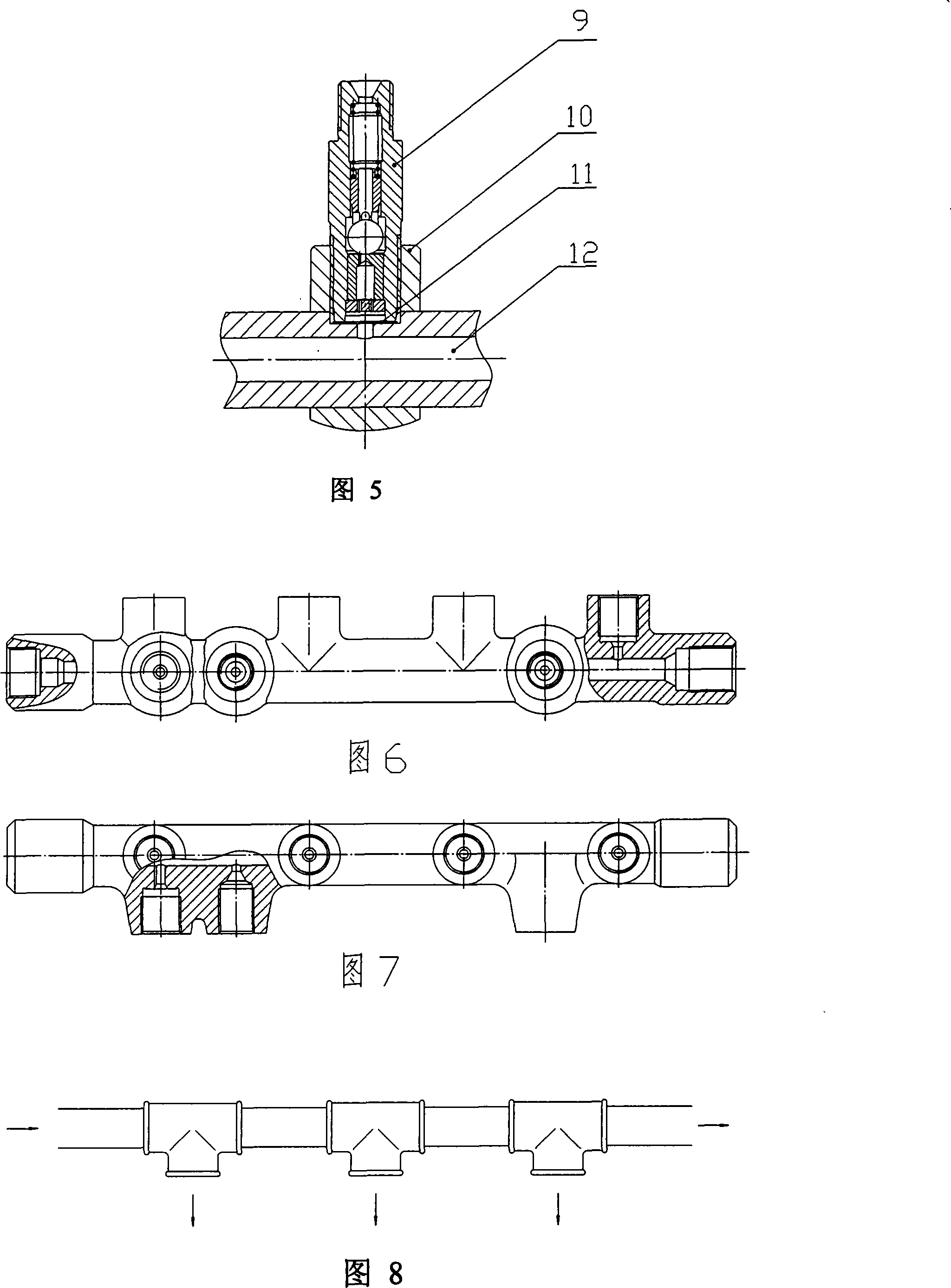

[0039] Figure 6 and Figure 7 show the traditional one-piece common rail pipe. Its main pipe, oil inlet joint, oil outlet joint, safety valve joint, and oil pressure sensor joint are made of cast steel to form a whole. Oil pipe joint (connected to high-pressure pump), flow limiting valve (connected to fuel injector), safety valve (drain oil when oil pressure is too high) and oil pressure sensor. The common rail pipe accepts the high-pressure fuel from the high-pressure pump, and the fuel pressure is above 120MPa. The traditional common rail pipe is made of cast steel. Since the cast steel is prone to defects such as pores, sand holes, and shrinkage porosity, the scrap rate is high.

[0040] The application structure of the present invention on the high-pressure common rail pipe of the electric injection diesel engine. See Figure 3, Figure 4, Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com