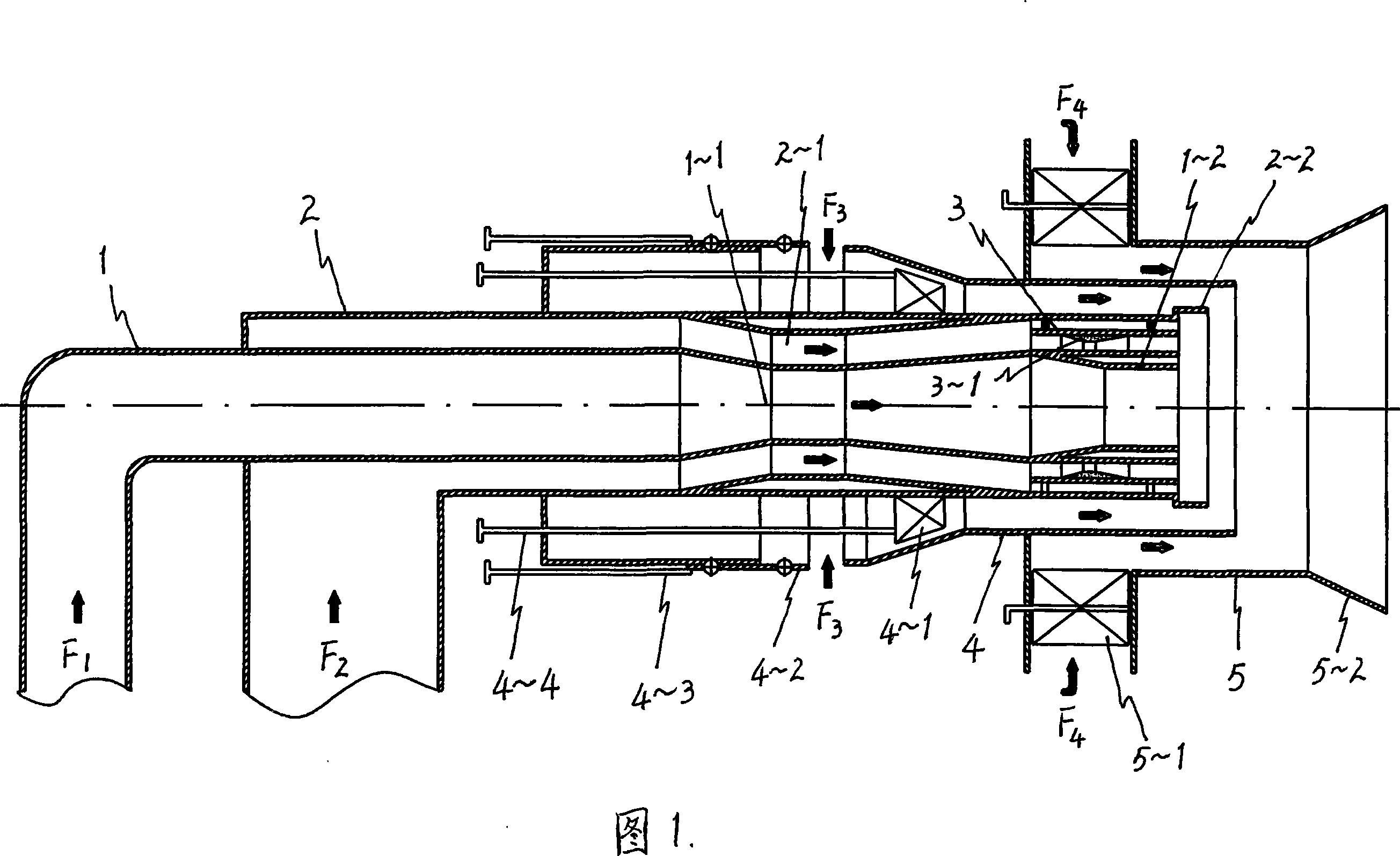

Double cyclone pulverized coal burner

A burner and double-swirl technology, applied in the direction of burners, burners burning powder fuel, combustion methods, etc., can solve the problems of easy wear of oil guns, increase of primary wind resistance, obstruction, etc., and achieve nitrogen oxides Low emissions, small flow resistance coefficient, and good combustion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The total length of the burner is 3834mm, of which: the main body of the central air duct 1 has a length of 2978mm, an inner diameter of φ416mm, and a wall thickness of 10mm. , length 300mm, front funnel-shaped beam tube 1~2 with a flare angle of 7°, inner diameter of straight pipe section φ337mm, both lengths are 300mm; main nozzle 2 length mm, large inner diameter φ700mm, wall thickness 13mm, Venturi section The angles of the tapering section and the expanding section of 2~1 are also 15° and 12° respectively, the inner diameter of the straight section is φ568mm, and the length is also 300mm, and the "L" type flare 2~2 has an inner diameter of φ768mm and an axial length of 120mm; The inner diameter of ring 3 is φ580mm, the axial length is 600mm, and the wall thickness is 4mm. The length of Venturi section 3~1 is 276mm, the angle of tapered section is 16°, the angle of tapered section is 11°, and the inner diameter of straight section is φ283mm (about 50mm in length. );...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com