Ultrasonic liquid combusting oven

An ultrasonic wave and stove body technology, which is applied in the field of ultrasonic liquid-burning stoves, can solve problems such as insufficient combustion, easy fires, and easy fuel leakage, etc., and achieve the effects of being conducive to burning, not easy to fire, and stable flames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

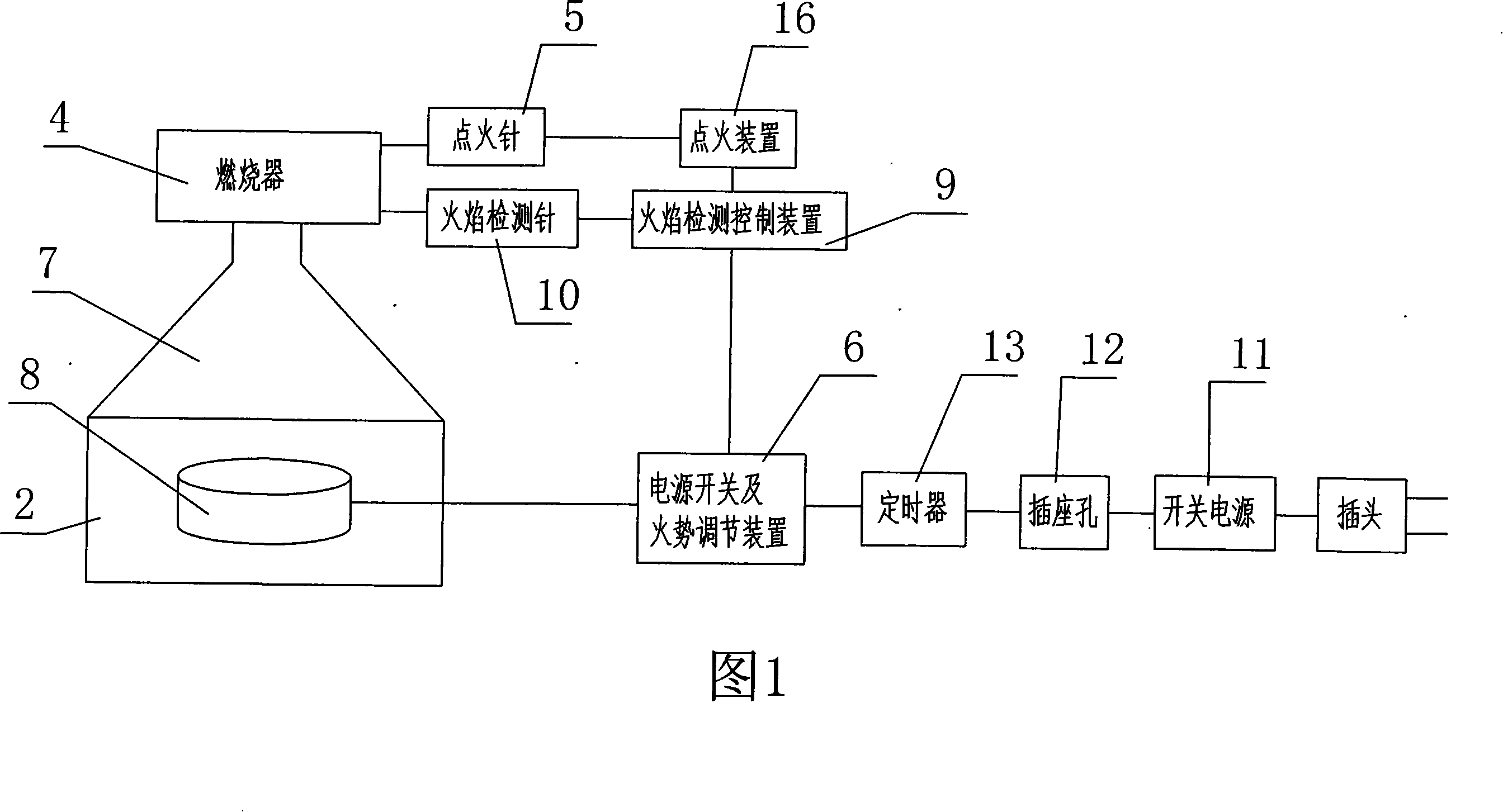

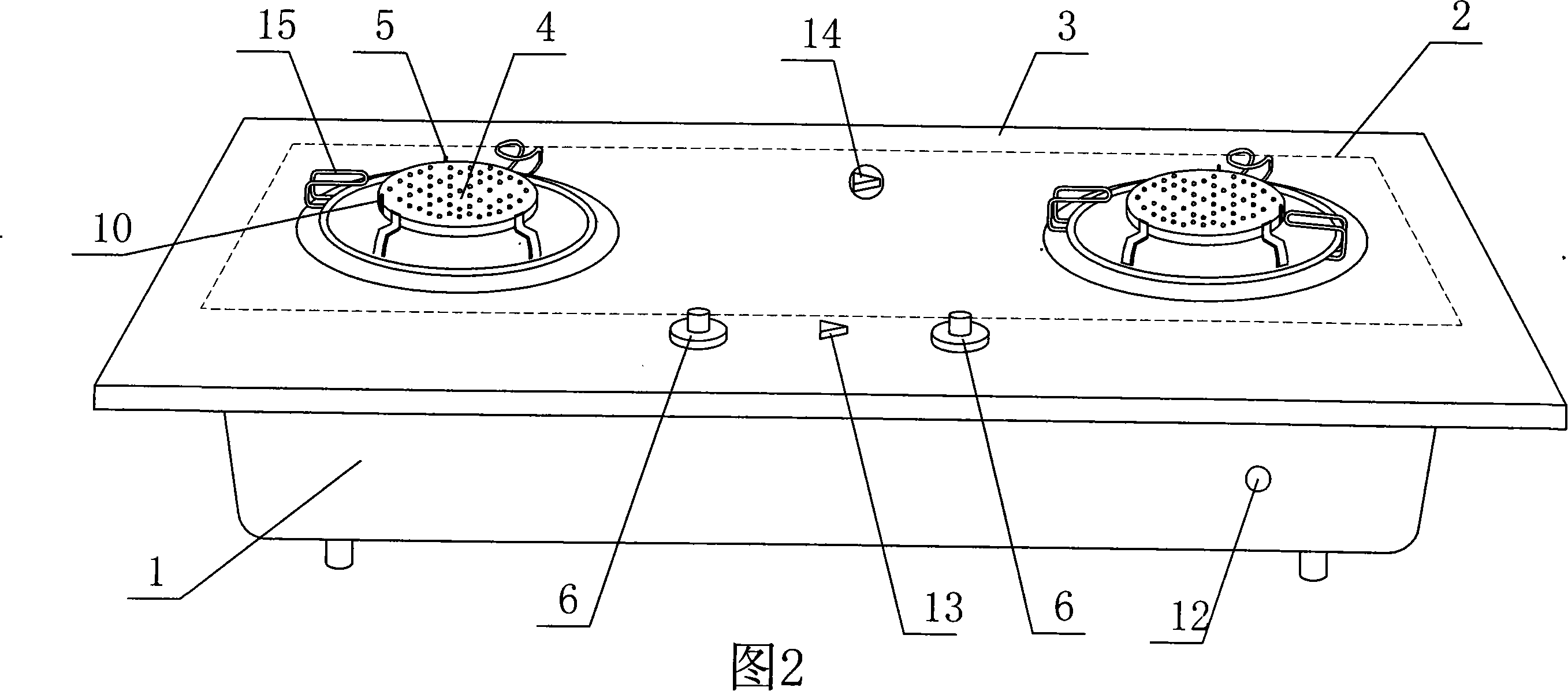

[0017] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments:

[0018] As shown in Fig. 1 and Fig. 2, it is an embodiment of an ultrasonic liquid-burning stove provided by the present invention, which includes a stove body 1 and a container box 2 for containing liquid fuel, and a burner 4 is installed on the panel 3 of the stove body, A fuel conveying device 7 is provided between the container box and the burner, and it is characterized in that: an ultrasonic oscillator 8 is provided in the container box, the ultrasonic oscillator is connected to the power supply through the power switch 6, and the ultrasonic oscillator is started when the power switch is turned on Generates oscillating ultrasonic waves used to mist liquid fuel.

[0019] An ignition needle 5 controlled by an ignition device 16 is provided near the burner, and the ignition device is connected to the power supply through a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com