An experimental device for welding recondition on tubes in service

A welding repair and experimental device technology, applied in the direction of educational appliances, instruments, teaching models, etc., can solve the problems of high cost, high risk of in-service welding evaluation, etc., and achieve the effect of convenient operation, simple structure and safe process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

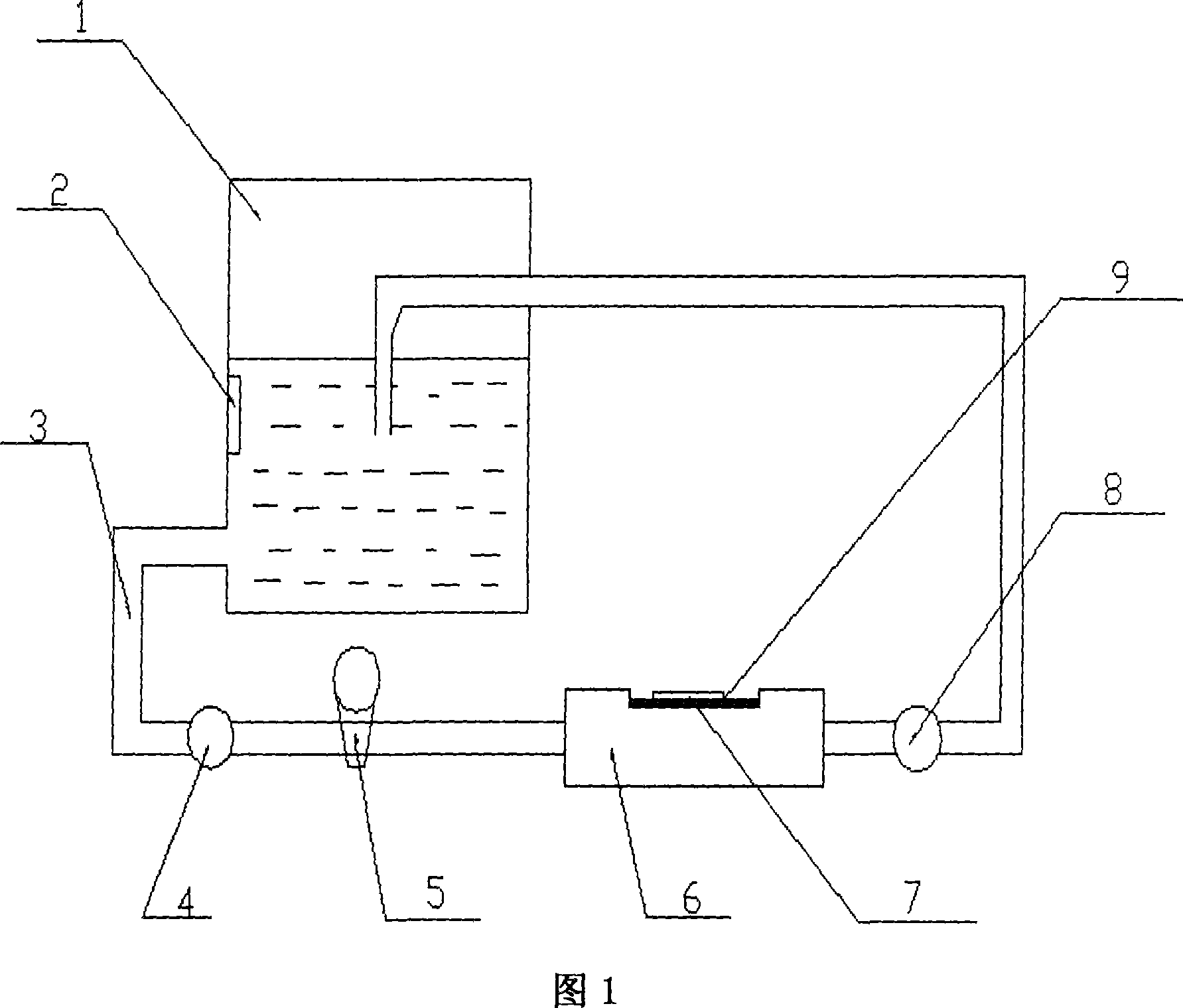

[0008] Figure 1 shows the in-service welding experimental device for pipelines provided according to the above technical characteristics. First cut out a groove in the pipe 6, process the pipeline steel material into bottom plates 7 of different thicknesses, stick the bottom plate on the groove of the pipe with 502 glue, and seal it well. Restoration plate 8 is placed on base plate, to be welded. Open the valve 5, adjust the high-pressure water pump 4, and measure different water flow rates through the flow meter 9. The water in the water tank returns to the water tank through the circulation loop 3. After the water flow rate measured by the flow meter is stable, the repair plate is welded on the bottom plate. After welding, the flowing medium inside the pipe performs forced convection heat exchange on the welded bottom plate, thereby rapidly reducing the temperature of the welded joint. After the welded joint is lowered to room temperature, the welded bottom plate and repai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com