Filter element

A filter element and inner core technology, which is applied in fixed filter element filters, filtration and separation, water/sludge/sewage treatment, etc. The effect of low differential pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

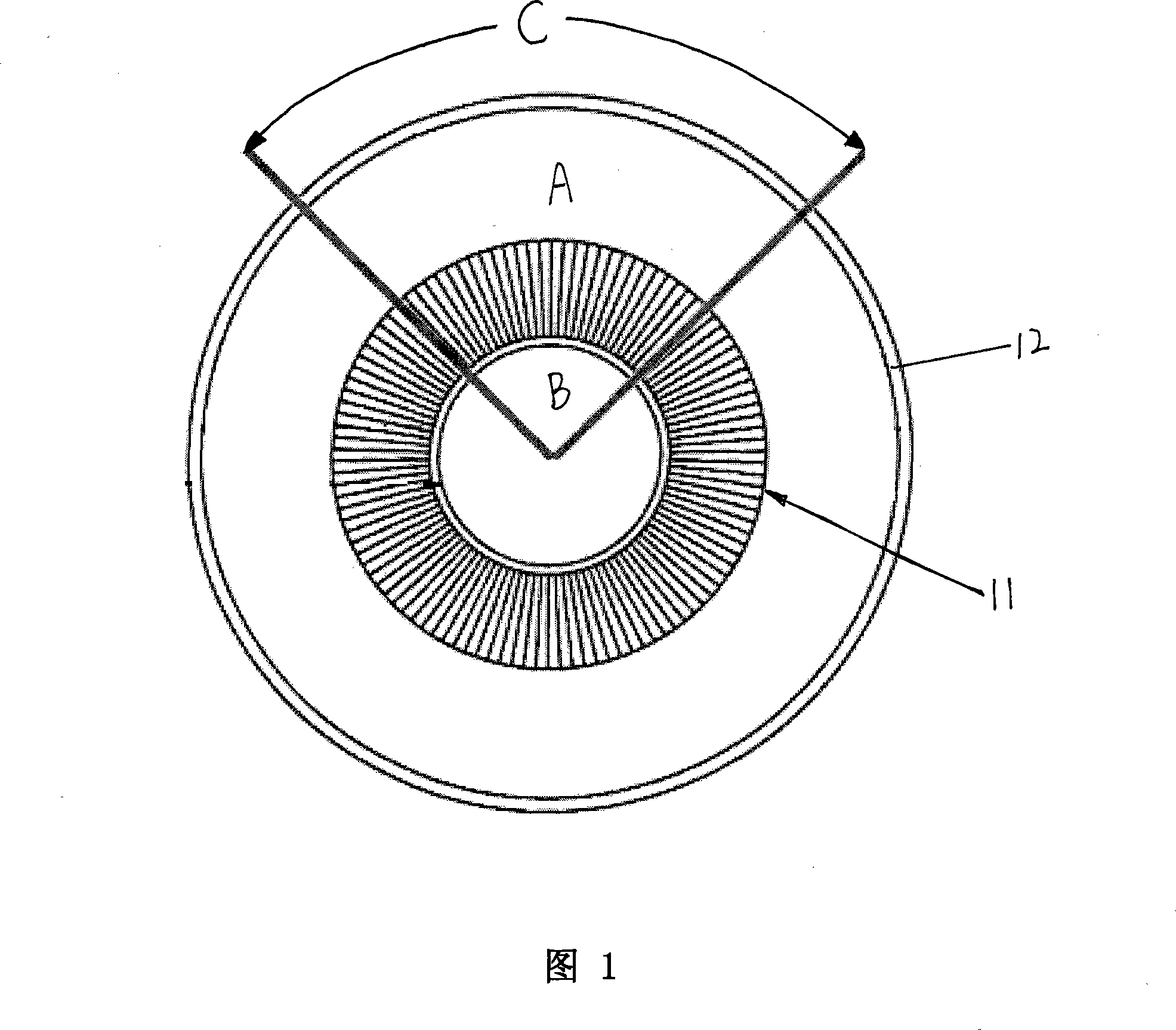

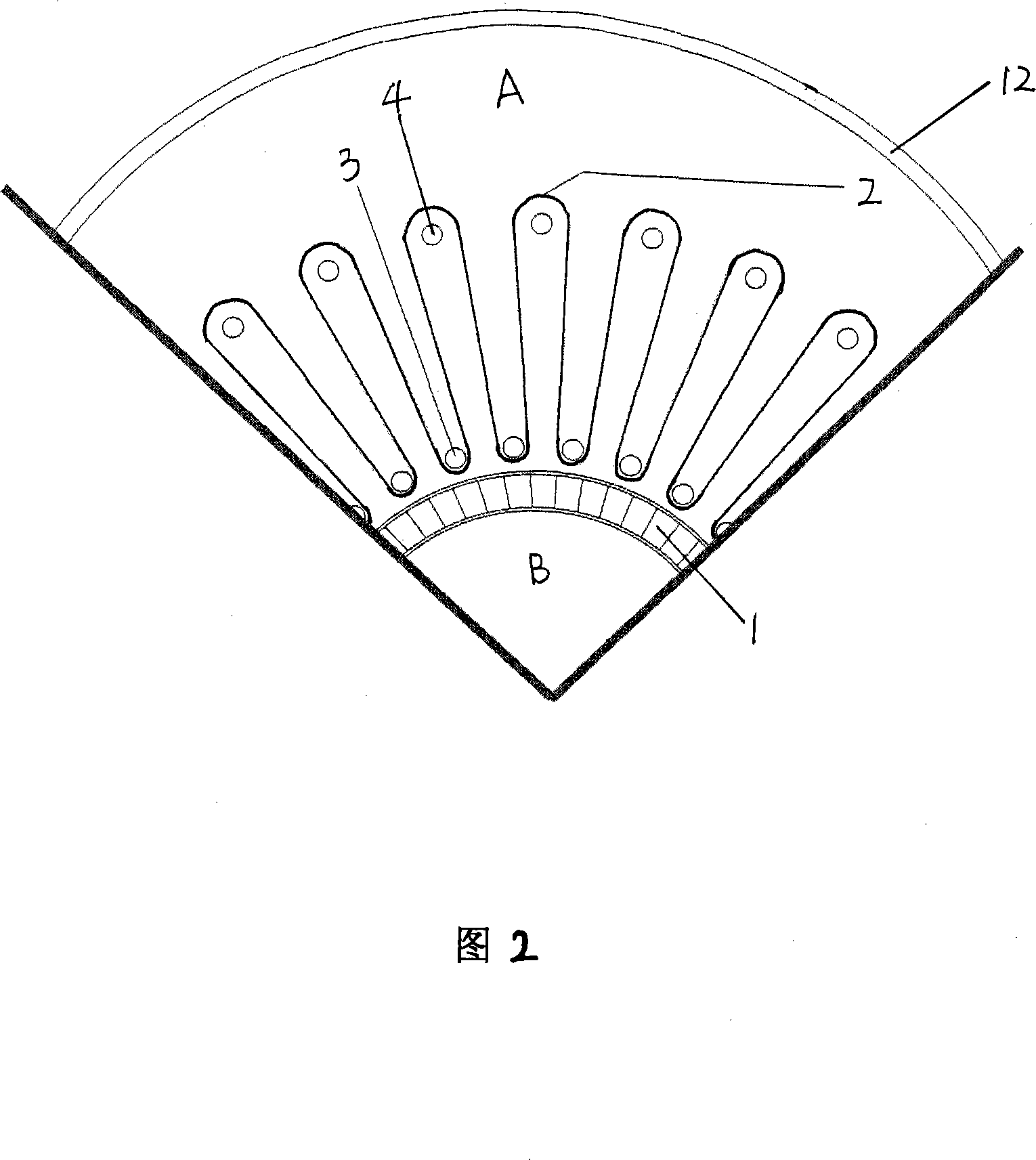

[0017] As shown in Figures 1 and 2, a filter element 11 includes a porous stainless steel inner core 1 and a biological filter membrane 2 arranged on the periphery of the porous stainless steel inner core 1, and the filter element also includes a porous stainless steel inner core 1 arranged at intervals. A plurality of inner ring stainless steel brackets 3 and a plurality of outer ring stainless steel brackets 4 on the periphery, the spacing between every two adjacent inner ring stainless steel brackets 3 is equal, and the spacing between every two adjacent outer ring stainless steel brackets 4 equal. Inner ring stainless steel brackets 3 and outer ring stainless steel brackets 4 are staggered, and the distance between two adjacent inner ring stainless steel brackets is smaller than the distance between adjacent two outer ring stainless steel brackets; the biological filter membrane is γ - polyglutamic acid composite membrane, its pore size is 0.7 μ m, biological filtration me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com